A kind of equipment and method for manufacturing anhydrous nano montmorillonite

A nano-montmorillonite and nano-technology, applied in lighting and heating equipment, drying solid materials, non-progressive dryers, etc., to prevent agglomeration, eliminate heat resistance, and improve dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

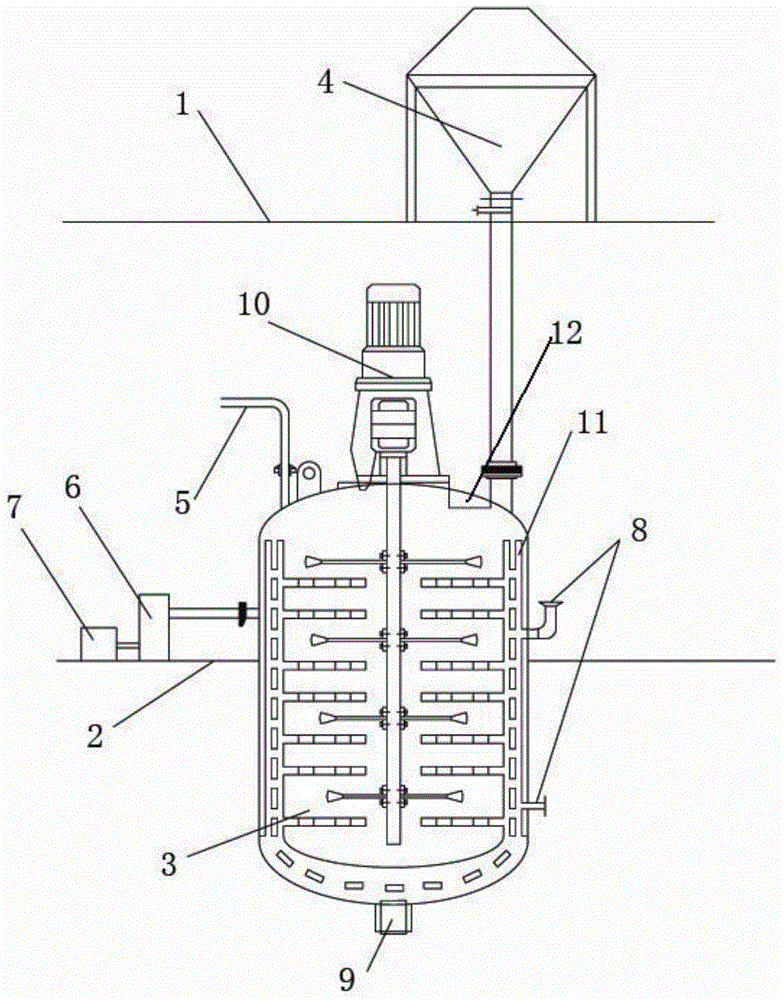

[0015] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and specific examples, the specific implementation, structure, characteristics and features of a three-dimensional dryer for nano-montmorillonite of the present invention will be described. Efficacy, in detail.

[0016] As shown in Figure 1, the present invention mainly comprises a first equipment platform 1, a second equipment platform 2, a dryer 3 and a metering device 4, the metering device 4 is fixed on the first equipment platform 1, and the dryer 3 is fixed on the second device Platform 2, the outer top of the dryer 3 is equipped with vibrating and shearing mixing equipment 10, the left side of the outer top is installed with a nitrogen filling pipeline 5, the right side of the outer top is connected to the metering device 4 through the pipeline, and the left side of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com