Negative-pressure back-fire smelting energy-saving and environment-friendly furnace for secondary lead

An energy-saving, environment-friendly, and lead-regenerating technology, applied in the field of smelting furnaces, can solve the problems of insufficient energy saving, easy environmental pollution, waste of heat, etc., and achieve the effects of energy saving, high combustion efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

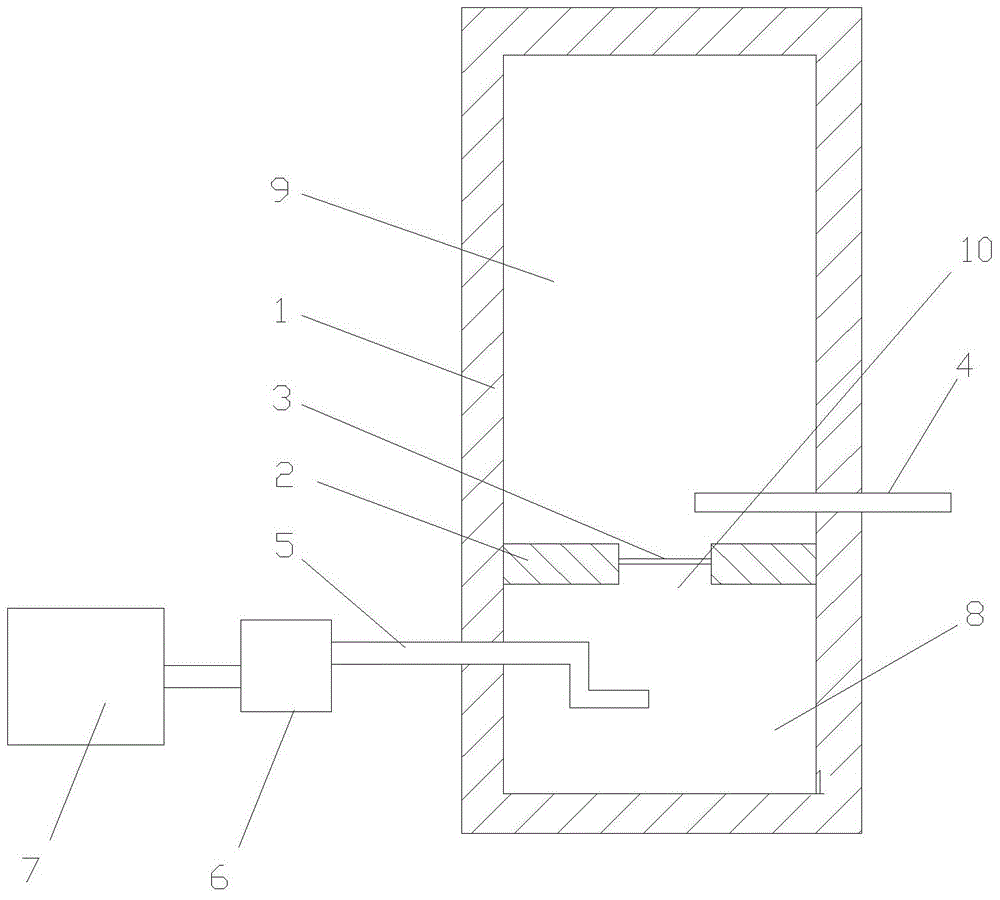

[0012] Such as figure 1 As shown, an energy-saving and environment-friendly furnace for negative pressure back-flame smelting of recycled lead comprises a furnace body 1, an interlayer 2, a filter screen 3, a combustion pipe 4, an exhaust pipe 5, an exhaust fan 6 and a waste gas treatment device 7; an interlayer 2 It is arranged inside the furnace body 1, and the interior of the furnace body 1 is divided into a lower combustion chamber 8 and an upper gas chamber 9, and an air hole 10 is arranged in the middle of the interlayer 2; the filter screen 3 is arranged inside the air hole 10; the combustion The pipe 4 is arranged on the upper part of the furnace body 1, and the inner end of the combustion pipe 4 is arranged in the gas chamber 9; The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com