Cooling tower packing with inclined folded waves

A cooling tower and waveform technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of insufficient cooling surface area, insufficient cooling effect, large ventilation resistance, etc., and achieve saving The effect of glue dosage, improved gluing method, and small ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

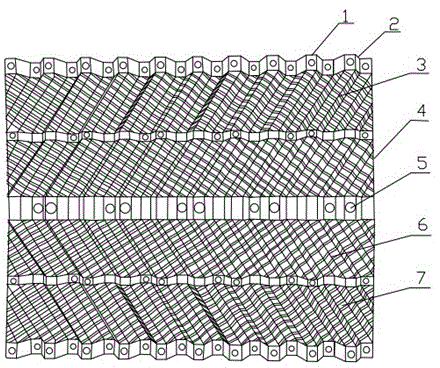

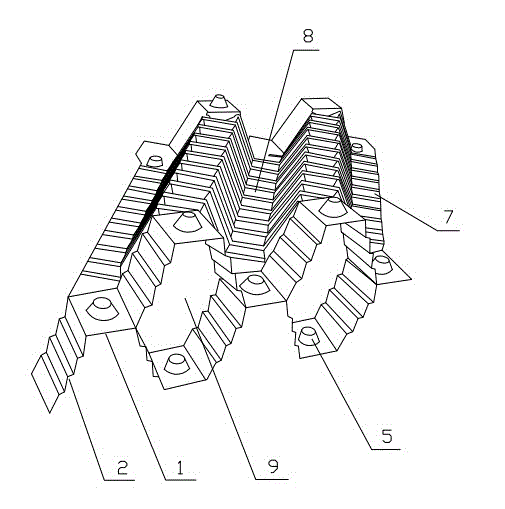

[0015] Such as figure 1 and 2 As shown, a kind of oblique wave packing for cooling towers includes a water spray plate 4, and the transverse edge of the water spray plate 4 is provided with a wave-shaped connecting edge 1; the cross-sectional shape of the wave-shaped connecting edge 1 is continuous without a bottom isosceles trapezoid, the two waists of the isosceles trapezoid are broken lines, forming a stepped connection side 2; the wave-shaped connection side 1 is provided with bonding points 5; between the step-shaped connection sides 2 There is a cooling wave 8; the cooling wave 8 includes an upper cooling wave 3 and a lower cooling wave 6, and the upper cooling wave 3 and the lower cooling wave 6 are symmetrically distributed with respect to the corrugated connection side in the middle; the surface of the cooling wave 8, etc. The spacing is provided with stagnat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com