Non-contact type converter valve temperature on-line monitoring method and device

A non-contact, converter valve technology, applied in the application of measuring devices, thermometers, thermometers, etc., can solve the problems of changing the electric field distribution of the converter valve, increasing the electric field, and being unsuitable for the on-line measurement method of the converter valve temperature, etc. Achieve the effect of good safety and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

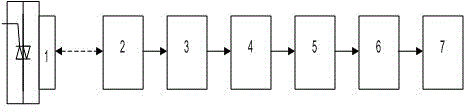

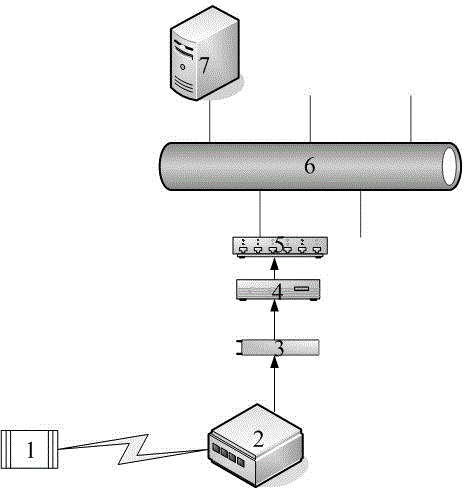

[0038] See figure 1 , The terminal of the present invention includes a passive RFID temperature sensor (1), a non-contact card reader (2) and a processor (3). The passive RFID temperature sensor (1) does not need power supply, it is pasted on the surface of the radiator of the converter valve, and it is in the high potential area. The model of the passive RFID temperature sensor (1) used in this implementation is SAW-C1.

[0039] The non-contact card reader (2) that can emit and receive electromagnetic signals is placed in the safe area on the edge of the valve hall of the converter station, the passive RFID temperature sensor (1) and the non-contact card reader (2) are not in direct contact and There is no electrical connection, the two transmit signals through electromagnetic waves, the non-contact card reader (2) transmits energy and reads tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com