Method for detecting subsurface crack of casting blank

A crack and slab technology, applied in the direction of color/spectral characteristic measurement, etc., to achieve the effects of fast cycle, improved contract fulfillment rate, and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

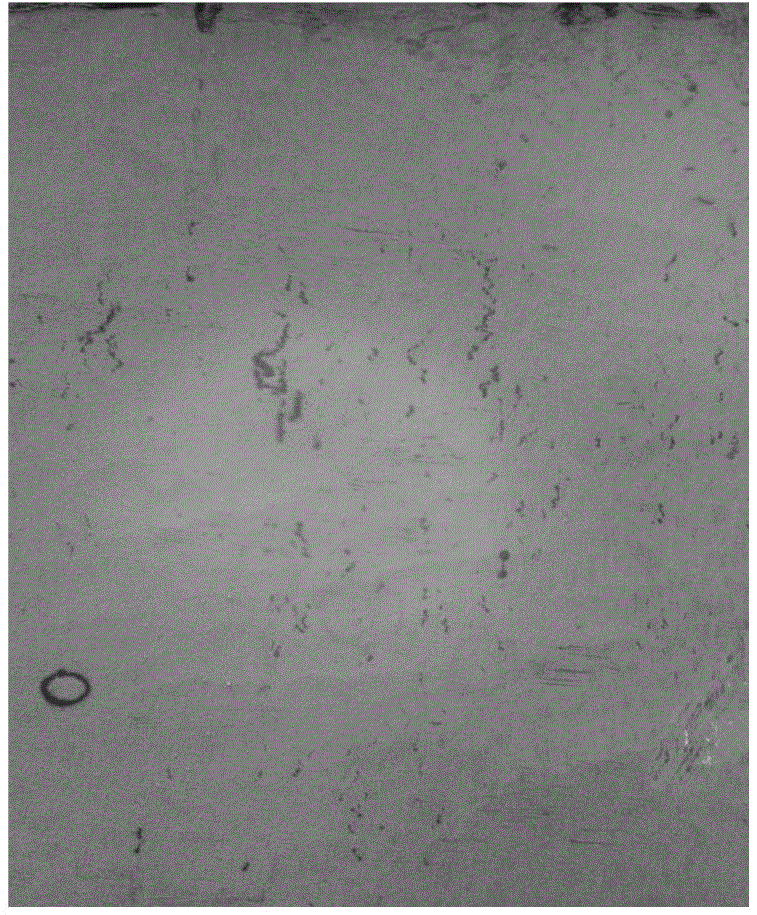

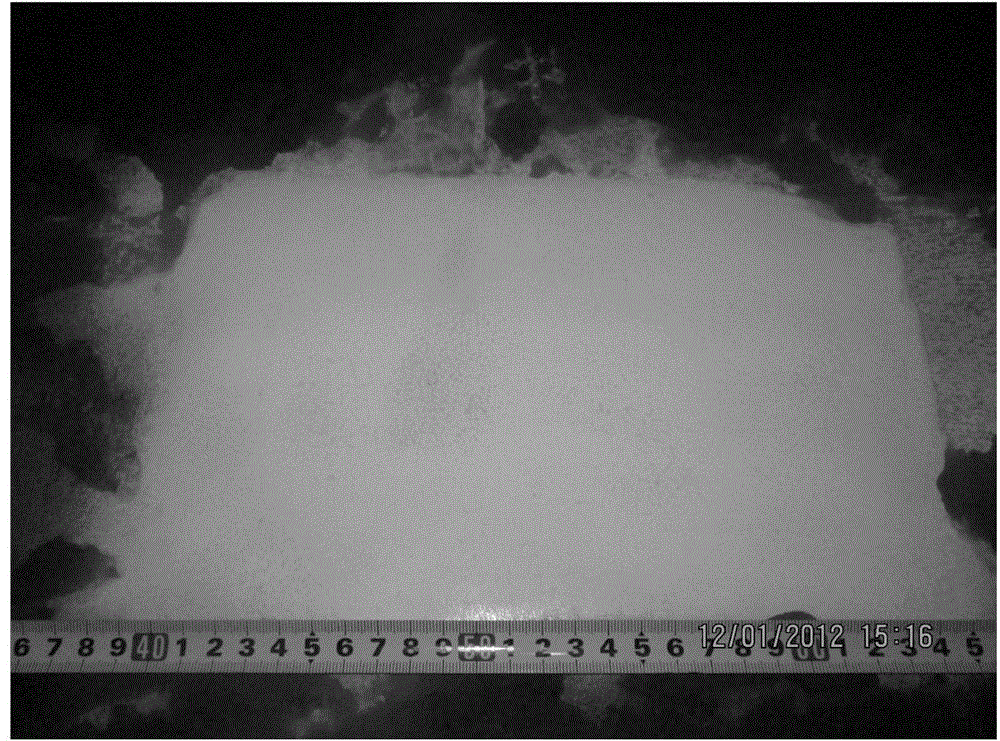

[0046] Taking the detection of cracks on the surface of the slab as an example, after using the above steps 1 to 5; if there are micro-cracks or cracks in the slab, the detection surface on the upper surface obviously shows dark stripes that are the same as the micro-cracks or cracks (Such as figure 1 shown), red stripes on site; if the slab has no micro-cracks or cracks, the detection surface on the upper surface of the slab only shows white developer (such as figure 2 shown).

Embodiment 2

[0048] The cracks in various parts such as the corners of the slab, which are difficult to sample, are used for detection.

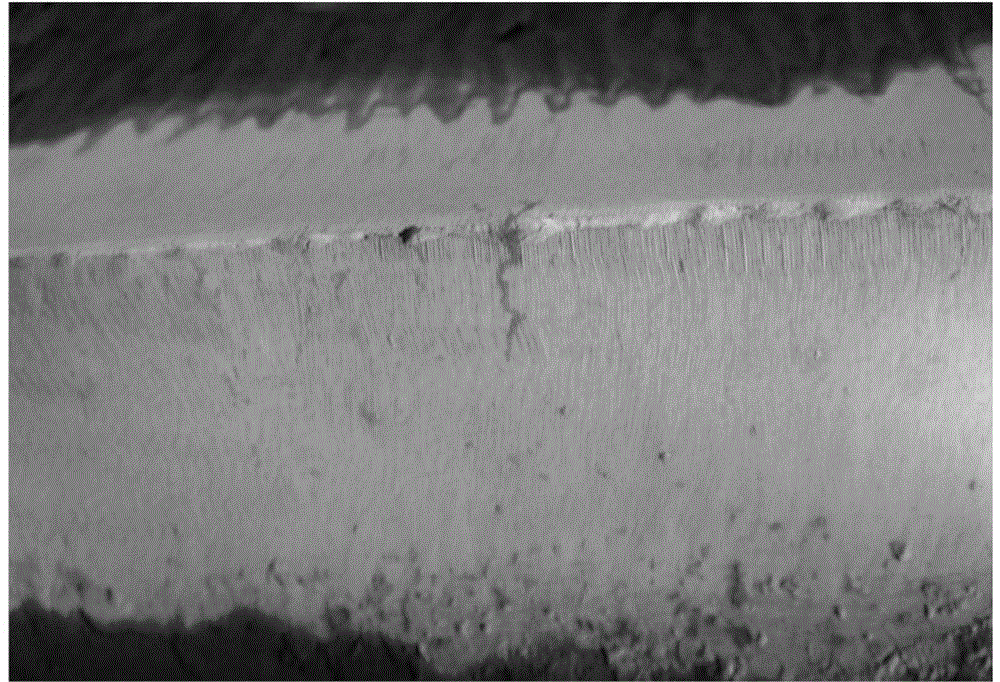

[0049] Taking the detection of cracks at the corners of the slab as an example, after using the above steps 1 to 5; if there are micro-cracks or cracks at the corners of the slab, the detection surface on the corner of the slab will obviously show the same morphology as the micro-cracks or cracks dark stripes (such as image 3 shown), red streaks in the field; if the slab has no micro-cracks or cracks, the detection surface of the corner surface of the slab only shows white developer (such as Figure 4shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com