Complete period dynamic optimization method for industrial ethylene cracking furnace and based on surrogate model

A technology of ethylene cracking furnace and proxy model, which is applied in the field of full-cycle dynamic optimization of industrial ethylene cracking furnaces, can solve problems such as the lack of implementation precedents in this regard, and achieve the effect of preventing overfitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A kind of full-cycle dynamic optimization method of an industrial ethylene cracking furnace based on a proxy model in this specific embodiment takes naphtha cracking as an example, but it is not limited to this, and it can also be used with gas phase raw materials, light naphtha, fuel oil, etc. Various cracking raw materials such as hydrogen tail oil and light diesel oil.

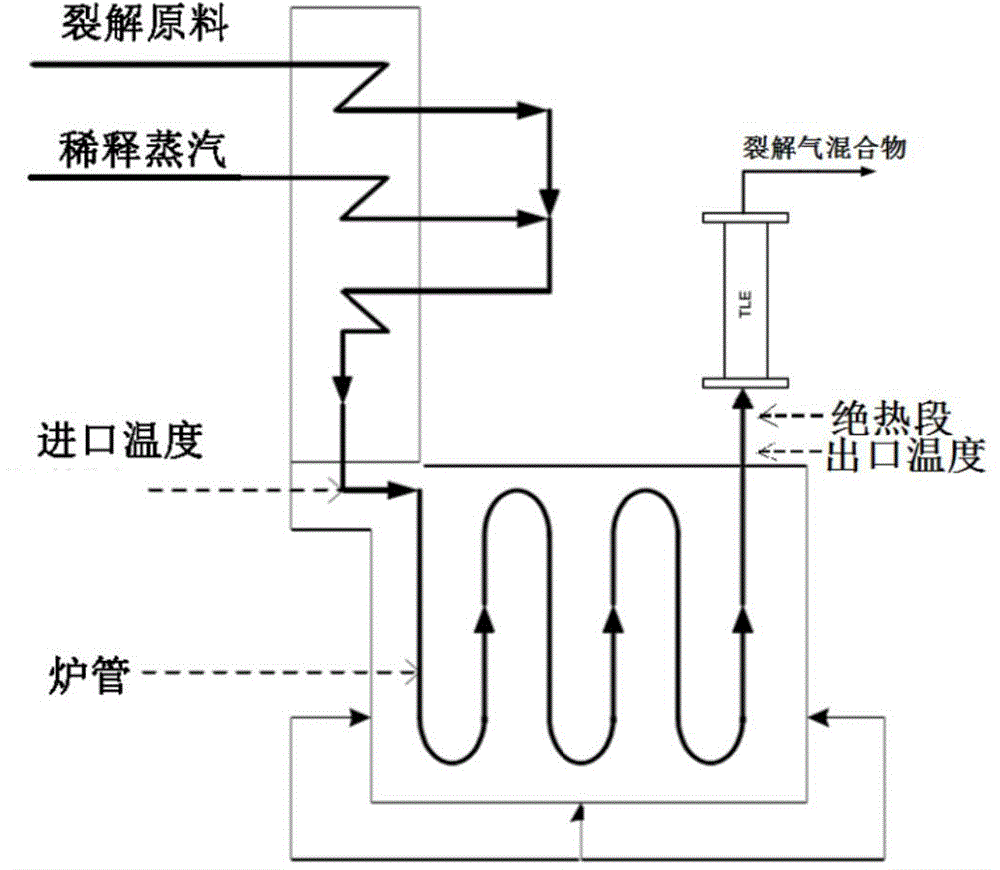

[0032] The industrial ethylene cracking furnace system of this concrete example is as figure 1As shown, the cracking raw material is preheated in the convection section of the cracking furnace, and then further overheated with the dilution steam in the convection section, and the hydrocarbon / steam mixture reaches about 500-600°C and enters the radiant tube of the cracking furnace. The fuel gas burns in the furnace, transfers heat to the radiant tube of the cracking furnace, and further heats the perhydrocarbon / steam mixture in the radiant section. At the outlet of the radiant section, the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com