Laser light power self-adaptation control method based on MCU

An adaptive control and laser technology, applied in the field of lasers, can solve the problems of unusable optical transmission modules, low availability of optical transmission modules, changes in laser luminous power, etc. The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

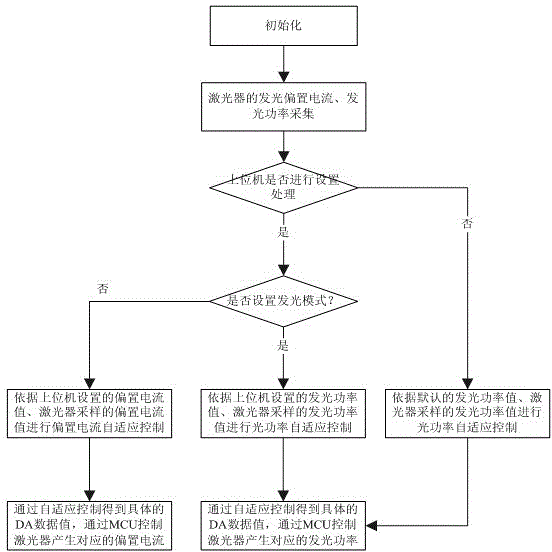

[0038] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail with reference to the accompanying drawings and embodiments below:

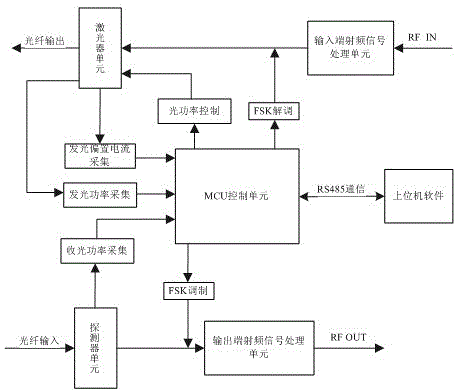

[0039] The Chinese name of MCU (Micro Control Unit) is a micro control unit, such as figure 1 The system used for MCU laser control in the prior art shown includes an MCU control unit, a laser unit, a detector unit, a radio frequency signal processing unit at an input end, and a radio frequency signal processing unit at an output end. The output of the laser unit is output through the optical fiber, the input of the detector unit is input through the optical fiber, the input RF signal of the RF signal processing unit at the input end is marked as RF IN, and the output RF signal of the RF signal processing unit at the output end is marked as RF OUT.

[0040] The system generally sets the RF input port, and the RF signal RF IN is input from the RF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com