Dimensionally stable polyester yarn and preparation thereof

A technology of dimensional stability and polyester yarn, which is applied in the field of impregnated cords and the manufacture of such polyester multifilament yarns. It can solve the problems of non-usable yarns, unstable spinning process, etc., and achieve the effect of stable yarn production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0076] DMT-based polyethylene terephthalate chips having a relative viscosity of 2.04 have been spun at a temperature of 305°C, where the relative viscosity is measured in an Ubbelohde Viskosimeter (DIN 51562) at 25°C at 125 In-solution measurements in grams of 2,4,6-trichlorophenol in a mixture of phenol with a TCF:F ratio of 7:10 on a weight basis. A yarn count of 1440 dtex has been spun using a spinneret having 331 holes with a diameter of 800 μm. A 150 mm heating sleeve at a temperature of 200° C. was used below the spinneret. The spun filaments are then solidified in two steps by a gaseous cooling medium, wherein in a first cooling step the gaseous cooling medium flows transversely through a bundle of filaments and exits the bundle substantially on the side directly opposite the inflow, and in the second cooling step In the second cooling step, the tow is further cooled by self-absorption of a gaseous cooling medium around the tow. Heating sleeves and cooling have been ...

example 2

[0079] The spinning of polyester yarn was carried out as in Example 1, but the polyethylene terephthalate core was based on PTA, the relative viscosity was 2.18, and the spinning speed at the first godet was set as in Example 2A It is 4667m / min, and it is set to 4827m / min in Example 2B.

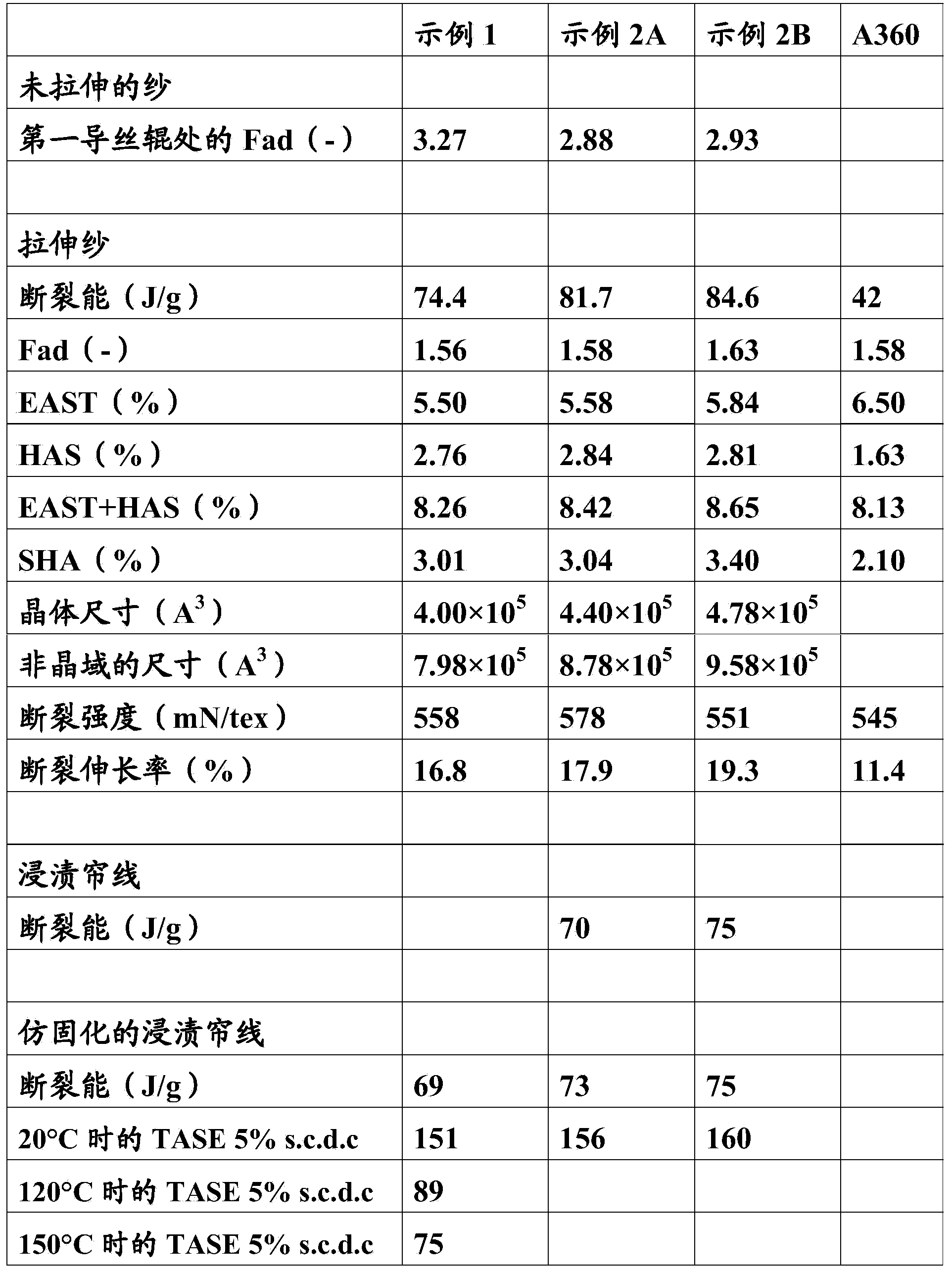

[0080] The properties of undrawn polyester yarns, drawn polyester yarns and simulated cured dipped cords are summarized in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture energy | aaaaa | aaaaa |

| Fracture energy | aaaaa | aaaaa |

| Fracture energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap