Automatic drilling machine and its control method for drilling holes in equal diameter positions of workpieces

An automatic drilling machine and equal-diameter technology, which is applied in the direction of automatic control devices, drilling/drilling equipment, boring/drilling, etc., can solve the problems of high production cost, labor consumption, unstable product qualification rate, etc., and achieve processing The effect of short time and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

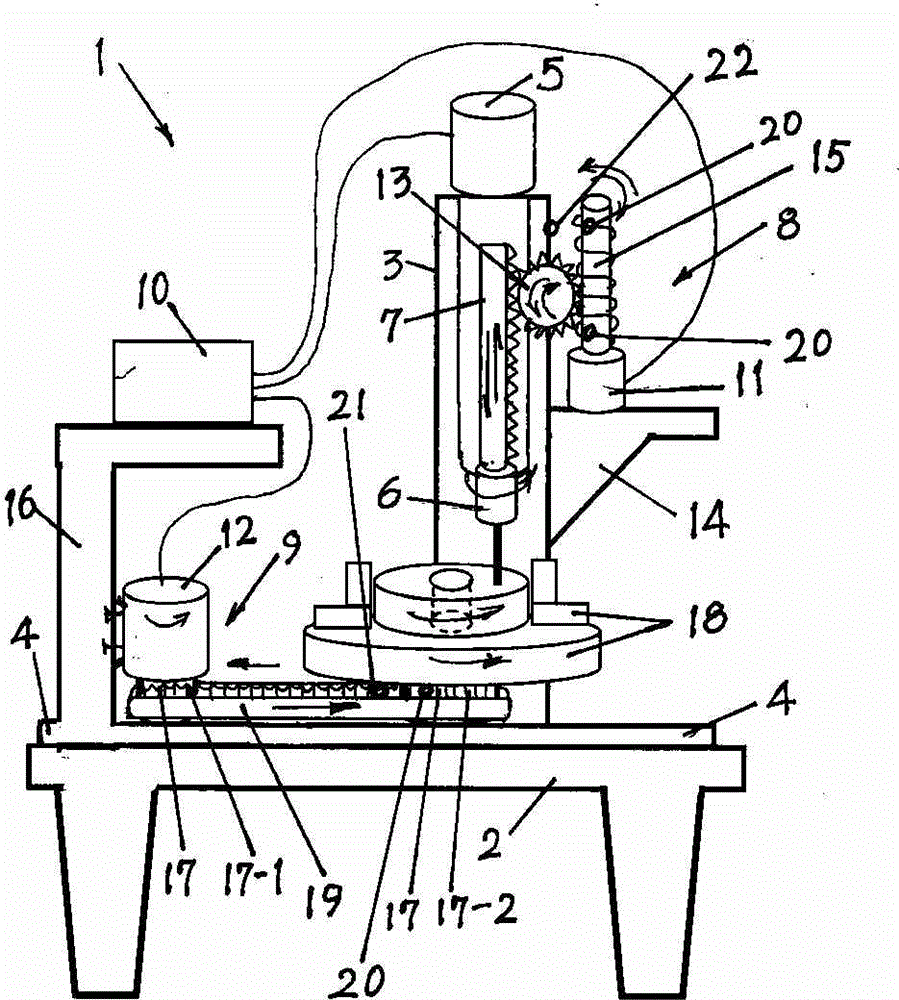

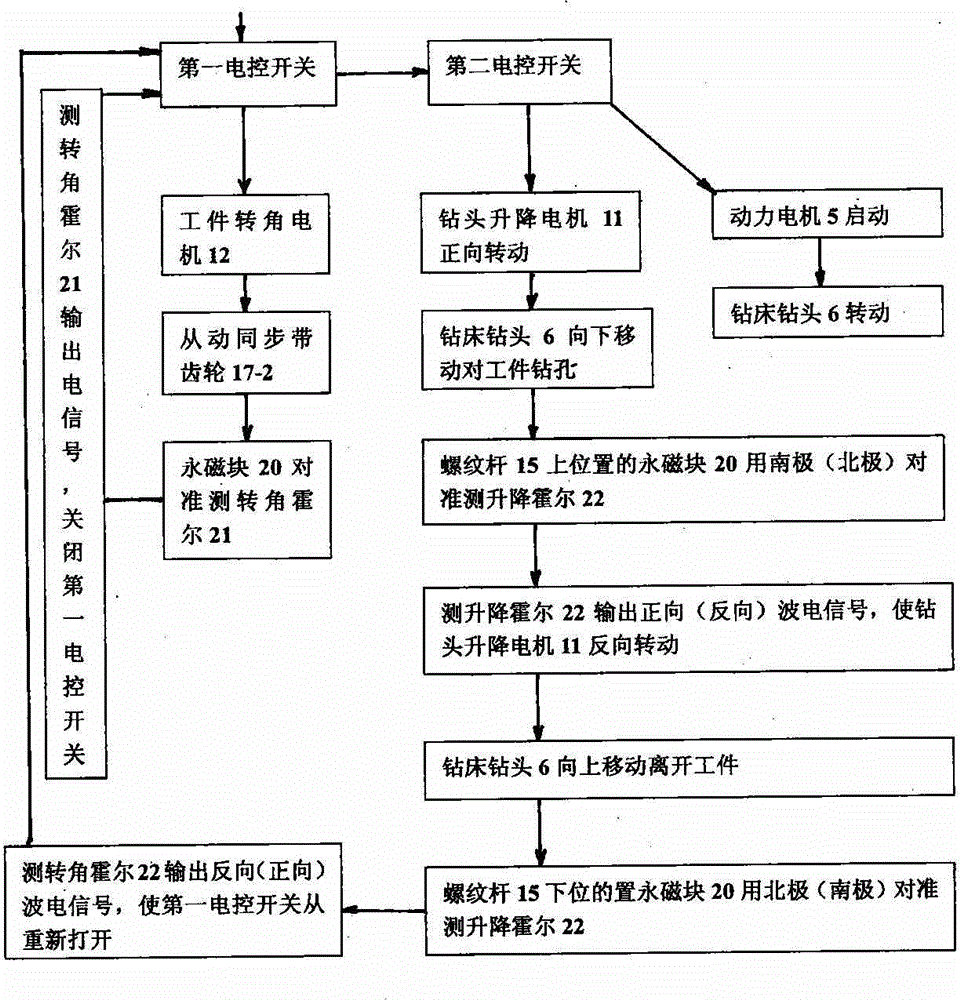

[0026] Embodiment 1, an automatic drilling machine and its control method for drilling holes at workpieces with equal diameters

[0027] An automatic drilling machine that drills holes in equal diameter positions of the workpiece, such as figure 1 , including a drill press 1 with the drill bit running vertically, a fixed drill bit support column 3 is erected on the base 2 of the drill press 1, a carrier plate 4 that is engaged and slidably connected with the base 2 is provided on the surface of the base 2, and the base 2 and the carrier A fixing mechanism for temporarily fixing the relative position is provided between the platen 4, and a power motor 5 is provided on the top of the drill support column 3, and the power motor 5 drives the drill bit 6 to rotate to process the workpiece, and the drill bit 6 is also connected to a control drill bit 6 The vertical toothed column 7 at the upper and lower positions, the rack of the vertical toothed column 7 is engaged with a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com