Automatic locking device of printing plate

An automatic locking and printing plate technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problem of easily scratching the surface of the printing plate cylinder, the long time spent changing the printing plate, and the influence of the degree of fit of the printing plate, etc. problems, to ensure integrity, save printing costs, and secure and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical solutions of the present invention, specific embodiments are used in the following to describe in detail with reference to the accompanying drawings.

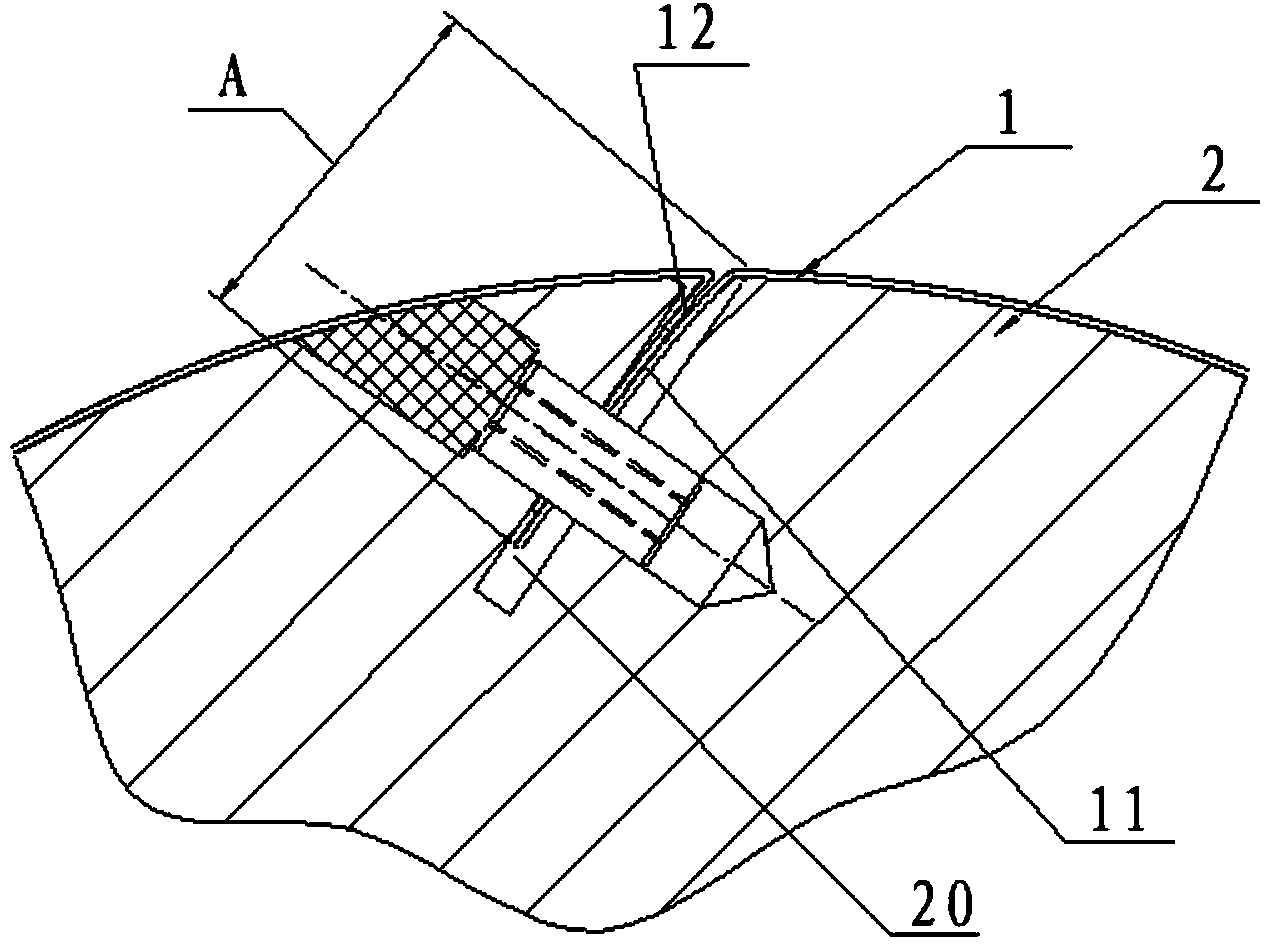

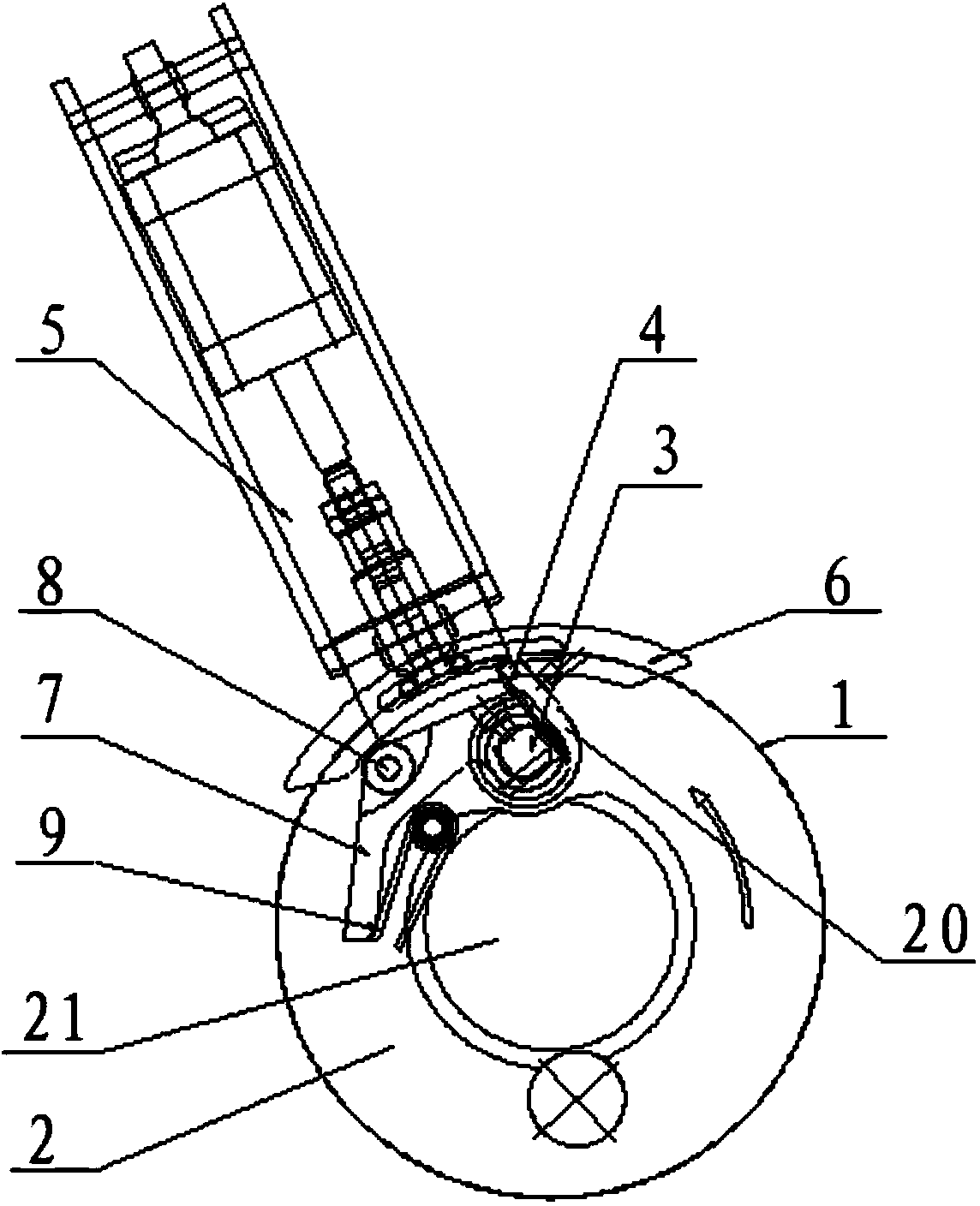

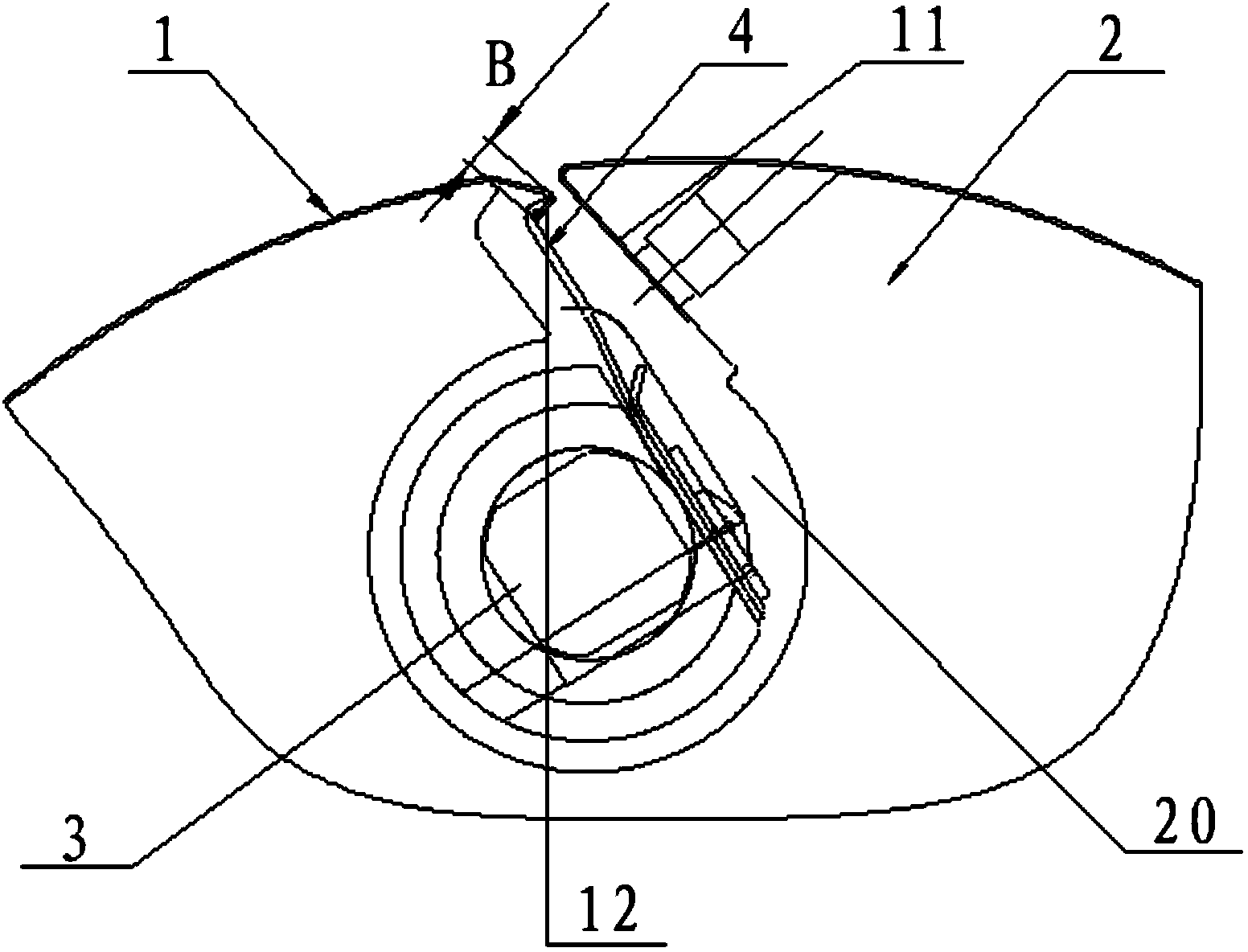

[0021] See Figure 2 to Figure 4 , The automatic locking device of the printing plate of the present invention includes a printing plate cylinder 2 on which a printing plate 1 is installed and a plate groove 20 is axially provided on the surface, and also includes a reel 3, a spring sheet 4, a cylinder 5, a cam 6, Link arm 7, bearing 8 and torsion spring 9, of which,

[0022] The two ends of the printing plate 1 are provided with a plate opening fold 11 and a plate fold 12 corresponding to each other, and the length of the plate fold 1 is B=1.8~2mm;

[0023] The bottom of the plate groove 20 of the plate cylinder 2 is a circular groove, and the upper part is a straight groove, so that the cross section of the plate groove is basically b-shaped, and the mouth of the groove wall on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com