High pressure hydrolysis tower

A hydrolysis tower and high-pressure technology, which is applied in the field of oleochemical industry, can solve the problems of insufficient contact between oil and water, separation of oil and water channels, and insufficient contact, etc., and achieve the effects of prolonging the contact time of oil and water, preventing non-contact, and increasing the contact area of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

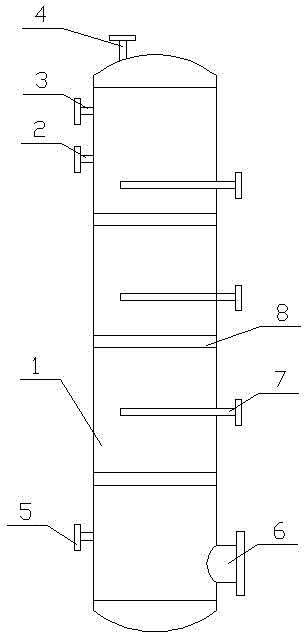

[0017] Such as figure 1 As shown in -3, the present invention comprises a tower body 1, the upper section of the tower body 1 is provided with a water inlet 2 and a discharge port 3, the upper end of the tower body 1 is provided with an exhaust port 4, and the lower section of the tower body 1 is provided with an oil inlet 5 and drain 6, the tower body 1 is provided with several steam distributors 7 from top to bottom, and a plurality of oil-water separators 8 are evenly distributed from top to bottom between the water inlet 2 and the oil inlet 5 in the tower body 1 .

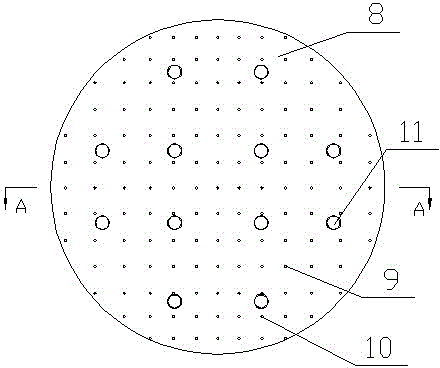

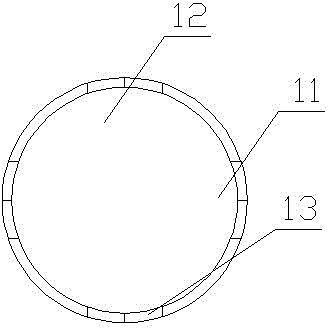

[0018] The oil-water separator 8 includes a circular separation disk 9, the outer wall of the circular separation disk 9 is sealed and fixedly connected with the inner wall of the tower body 1, and the circular separation disk 9 is evenly distributed with a plurality of water holes 10 and a plurality of The oil passage 11, the oil passage 11 passes through the circular separation disc 9 vertically upwards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com