Chewing gum scavenger

A technology of scavenger and chewing gum, which is applied in detergent composition, soap detergent composition, surface active non-soap compound and washing composition, etc. It can solve the problems of limited solubility and effect discount of natural rubber, and achieve fast and efficient Clear, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Best Practice

[0026] Add HO (C 4 h 2 o 5 Na) 6 H50g, CH 3 O(CH 3 CH 2 CH 2 O) 18 (CH 2 CH 2 O) 6 CH 3 0100g; 40 grams of ionic liquid, 10 grams of sodium lauryl sulfate, and 800 grams of ethanol were stirred at room temperature for 2 hours to obtain the chewing gum clearing liquid of the present invention.

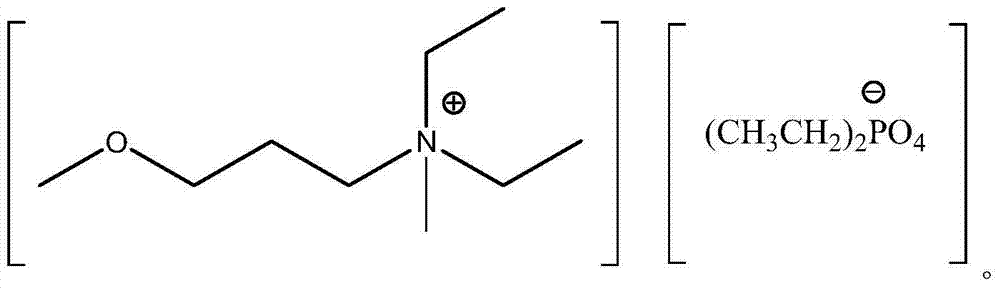

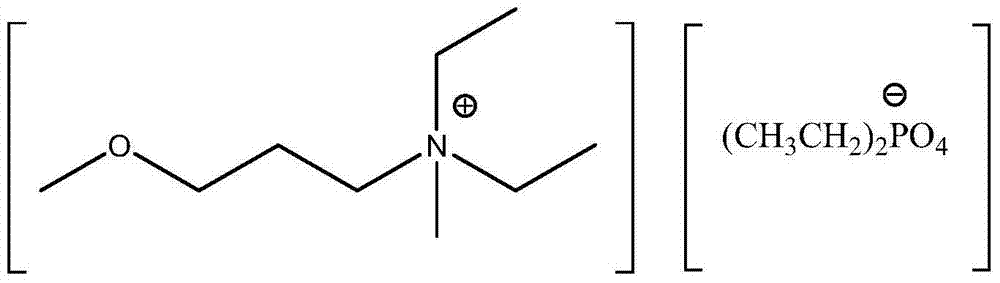

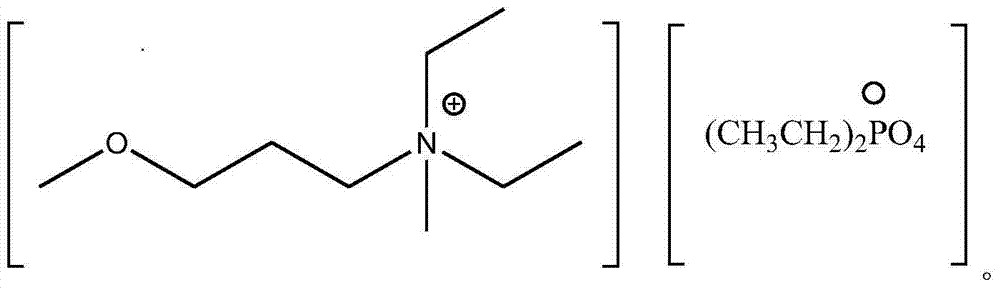

[0027] Wherein, the chemical formula of ionic liquid is:

[0028]

[0029] During use, the chewing gum residue on the ground is moistened with the scavenger of the present invention, fully dissolved, and then the softened and dissolved residue is gently removed with a toothbrush. The evaluation effect is divided into four levels according to complete removal, partial residue, ground damage, and difficult removal: excellent, good, poor, and very poor.

[0030] Effect: Excellent.

Embodiment 2

[0032] Substantially the same as the examples, except that the surfactant is HO (C 4 h 2 o 5 Na) 8 H and CH 3 O(CH 3 CH 2 CH 2 o) 19 (CH 2 CH 2 O) 7 CH 3 O mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com