Fermentation technology for increasing the aureomycin yield by adding metal ions

A technology of adding metal and fermentation process is applied in the field of fermentation process optimization of chlortetracycline, and achieves the effects of low production cost, simple operation, and improvement of fermentation level and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

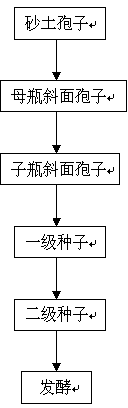

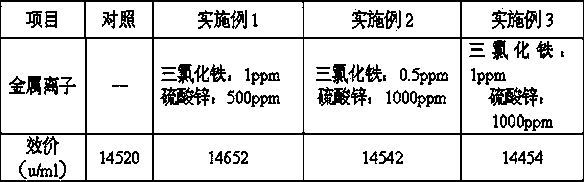

[0009] Example 1: Inoculate the slant spores of the mother bottle to the slant of the child bottle, and cultivate them for 3-5 days at a temperature of 32±1°C and a humidity of 40-65%; take the spores of the child bottle and inoculate them into the seed medium, cultivate at 28°C 20-26h; Inoculate in a fermentation shaker flask with 12% inoculum amount, culture at 28°C, 200r / min, for 166h. When preparing the fermentation medium, zinc sulfate and ferric chloride were added thereto, so that the concentrations of zinc ions and iron ions in the fermentation shake flask were 500ppm and 1ppm respectively.

Embodiment 2

[0010] Example 2: inoculate the slant spores of the mother bottle to the slant of the child bottle, and cultivate for 3-5 days under the conditions of temperature 32±1°C and humidity 40-65%; take the spores of the child bottle and inoculate them into the seed medium, cultivate at 28°C 20-26h; Inoculate in a fermentation shaker flask with 12% inoculum amount, culture at 28°C, 200r / min, for 166h. When preparing the fermentation medium, zinc sulfate and ferric chloride were added thereto, so that the concentrations of zinc ions and iron ions in the fermentation shake flask were 1000ppm and 0.5ppm respectively.

Embodiment 3

[0011] Example 3: Inoculate the slant spores of the mother bottle to the slant of the child bottle, and cultivate them for 3-5 days at a temperature of 32±1°C and a humidity of 40-65%; take the spores of the child bottle and inoculate them into the seed medium, cultivate at 28°C 20-26h; Inoculate in a fermentation shaker flask with 12% inoculum amount, culture at 28°C, 200r / min, for 166h. When preparing the fermentation medium, zinc sulfate and ferric chloride were added thereto so that the concentrations of zinc ions and iron ions in the fermentation shake flask were 1000ppm and 1ppm respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com