Method for reconstructing three-dimensional temperature field positioned on blast furnace wall and computer monitoring system

A technology of three-dimensional temperature and blast furnace, which is applied in the direction of blast furnace, blast furnace details, furnace, etc., can solve the problems of unintuitive overall temperature distribution, abnormal temperature measurement point data, and isolated temperature measurement point data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

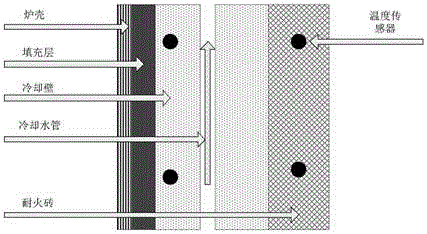

[0051] figure 1 It is a schematic diagram of the structure of the blast furnace wall, in which the installation position of the temperature measuring thermocouple is marked, the inner wall is installed at the center of the refractory brick, and the outer wall is installed at the center of the outer stave. The data of the temperature measurement points on the furnace wall (that is, the positions where the temperature measurement thermocouples are installed) are the data sources in the subsequent method and system design. In order to better understand the technical solution of the present invention, the implementation of the present invention will be further described below in conjunction with the accompanying drawings in the description and the specific blast furnace production data of a large-scale high-speed iron and steel enterprise in Hunan. The company is using a concrete blast furnace with an effective volume of 1000m 3 , chunky type, hearth diameter 7.7m 3 , 20 air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com