Steel frame insulation exterior wall panels

A technology of exterior wall panels and thermal insulation panels, which is applied in building components, thermal insulation, sound insulation, etc., to achieve the effects of improving room availability, convenient construction, and easy positioning and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

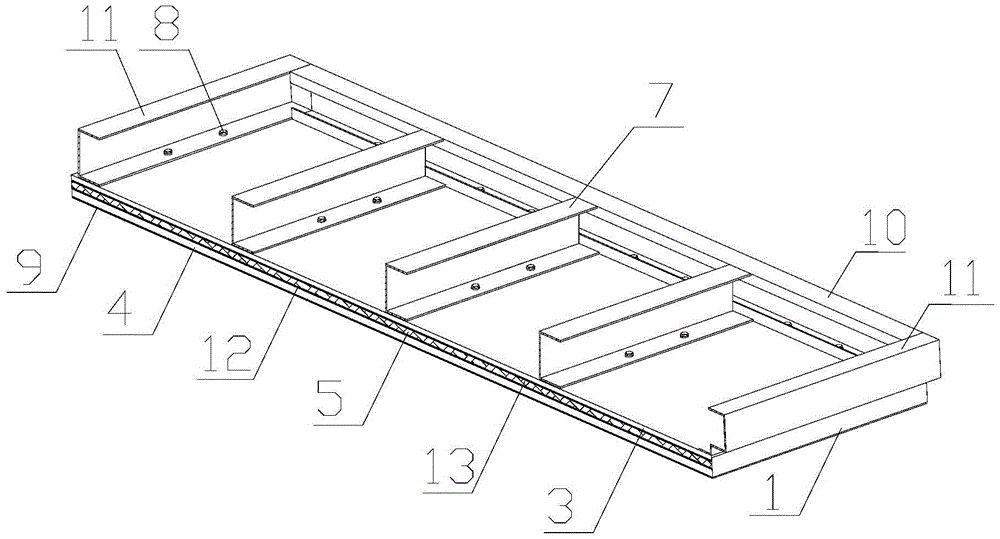

[0041] figure 2 It is a cross-sectional view of the three-dimensional structure of the steel frame heat-insulating exterior wall panel of the present invention (both the inner and outer protective layers are calcium silicate boards treated with waterproofing), Figure 4 It is a joint joint diagram between the steel frame thermal insulation exterior wall panels of the present invention.

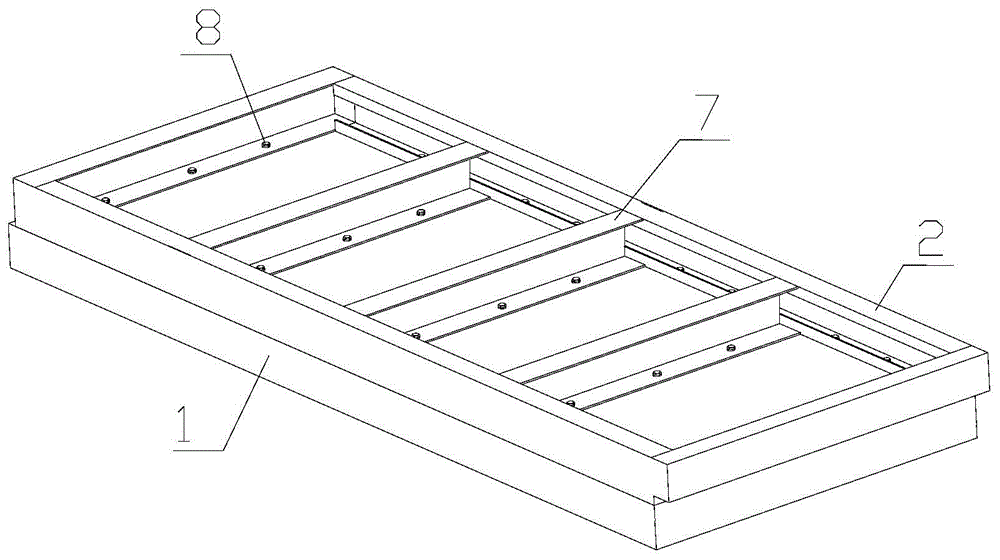

[0042] like figure 1As shown, the steel frame thermal insulation exterior wall panel provided by the present invention includes a composite thermal insulation panel 1 with a thickness of 45 mm, a steel frame 2 with a height of 100 mm and bolts 8 . The steel frame 2 includes longitudinal side ribs 10 with a height of 100mm, transverse side ribs 11 with a height of 100mm and stiffeners 7 with a height of 100mm. The longitudinal side ribs 10 and the transverse side ribs 11 form a rectangular frame, and there are multiple stiffeners 7 arranged in the rectangular frame surrounded by the longitud...

Embodiment 2

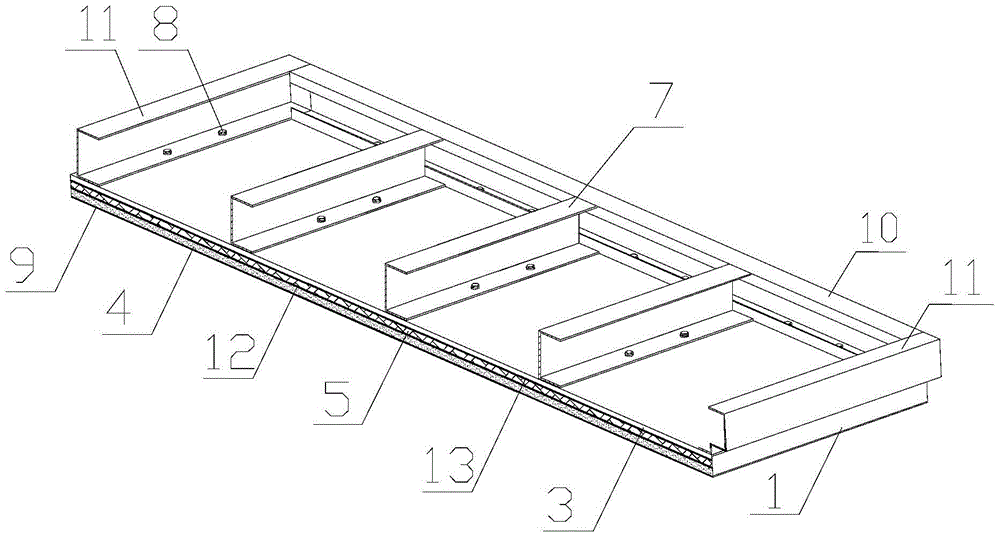

[0045] image 3 It is a sectional view of the three-dimensional structure of the steel frame thermal insulation exterior wall panel of the present invention, Figure 4 It is a joint joint diagram between the steel frame thermal insulation exterior wall panels of the present invention.

[0046] like image 3 As shown, the steel frame thermal insulation exterior wall panel provided by the present invention includes a composite thermal insulation panel 1 with a thickness of 45 mm, a steel frame 2 with a height of 100 mm and bolts 8 . The steel frame 2 includes longitudinal side ribs 10 with a height of 100mm, transverse side ribs 11 with a height of 100mm and stiffeners 7 with a height of 100mm. The longitudinal side ribs 10 and the transverse side ribs 11 form a rectangular frame, and there are multiple stiffeners 7 arranged in the rectangular frame surrounded by the longitudinal side ribs 10 and the transverse side ribs 11 . The composite thermal insulation board 1 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com