Transmission planetary gear carrier with support shaft and production process thereof

A technology of planetary gear carrier and production process, which is applied in the direction of belt/chain/gear, transmission device parts, mechanical equipment, etc., can solve the problems of high production cost, many processing procedures, not easy to loosen, etc., and achieve high internal tissue density, Good comprehensive mechanical properties, reducing the effect of cutting and milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

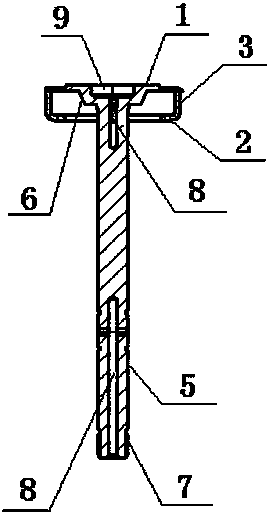

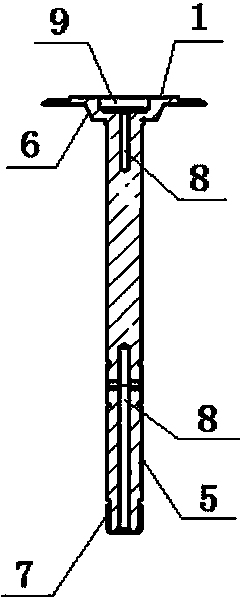

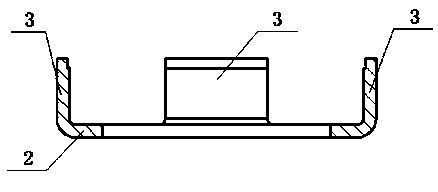

[0043] see figure 1 , figure 2 , image 3 and Figure 4 As shown, a transmission planetary gear carrier with a support shaft includes a support plate 1, a hollow cover plate 2 arranged parallel to the support plate 1, and four legs 3 connecting the support plate 1 and the hollow cover plate 2. The hollow cover plate 2 and the legs 3 are a curved integral structure, the support plate 1 and the legs 3 are welded, the support plate 1 is a circular structure, and the diameter of the support plate 1 is 110 mm. The support plate 1 and the hollow cover plate 2 respectively have a plurality of gear holes 4 for mounting pinions thereon, the middle part of the support plate 1 runs through the hollow cover plate 2 and is provided with a support shaft 5, and the support shaft 5 A frustum-shaped junction 6 is provided with the support plate 1, the supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com