Method for measuring shrinking percentage of inner cavity of hollow casting

A technology of casting inner cavity and shrinkage rate, which is applied in the direction of material thermal expansion coefficient, etc., can solve problems such as inability to guarantee numerical accuracy, high temperature capability close to the limit, and large gap in ceramic core size, so as to improve quality reliability and cooling efficiency , The effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

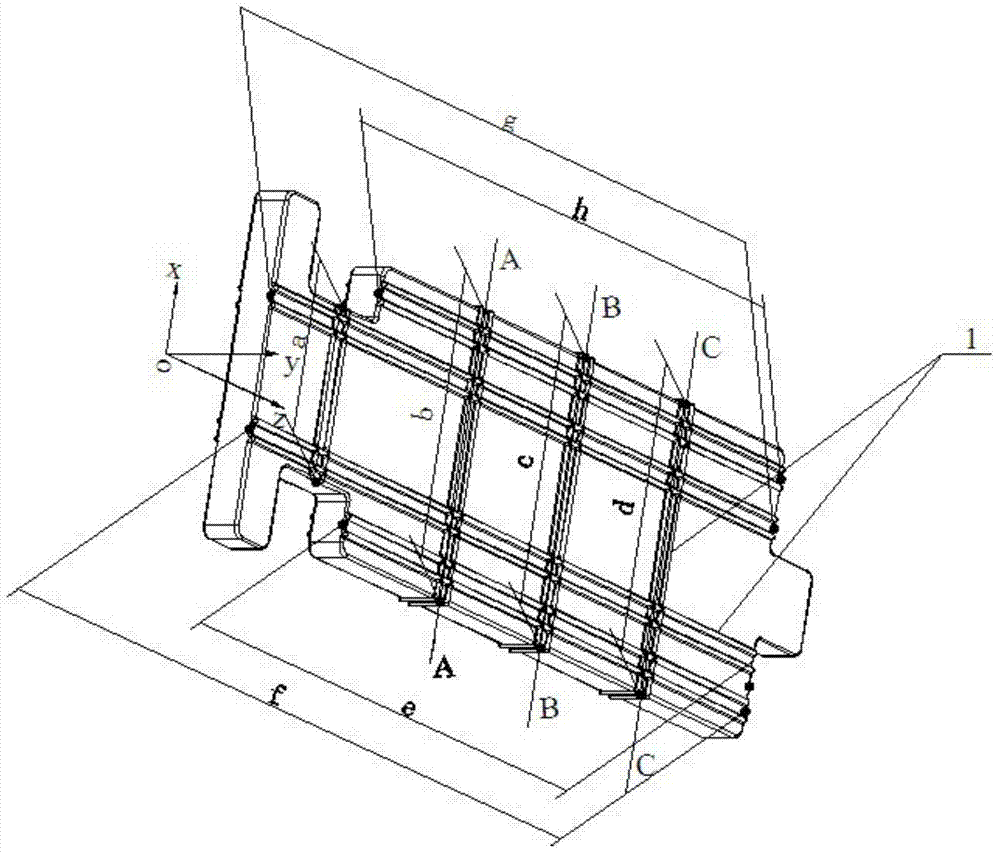

[0040] Embodiment 1, a method for measuring the shrinkage rate of the hollow casting of thick blades, specifically includes the following steps:

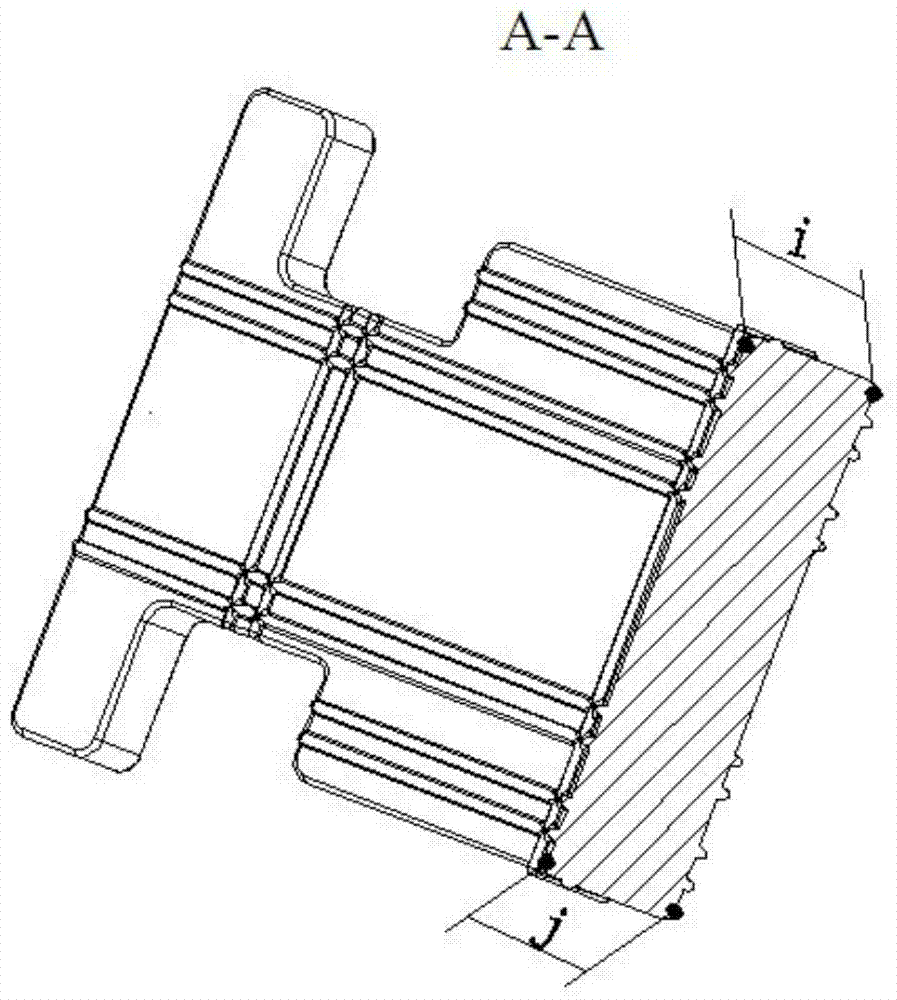

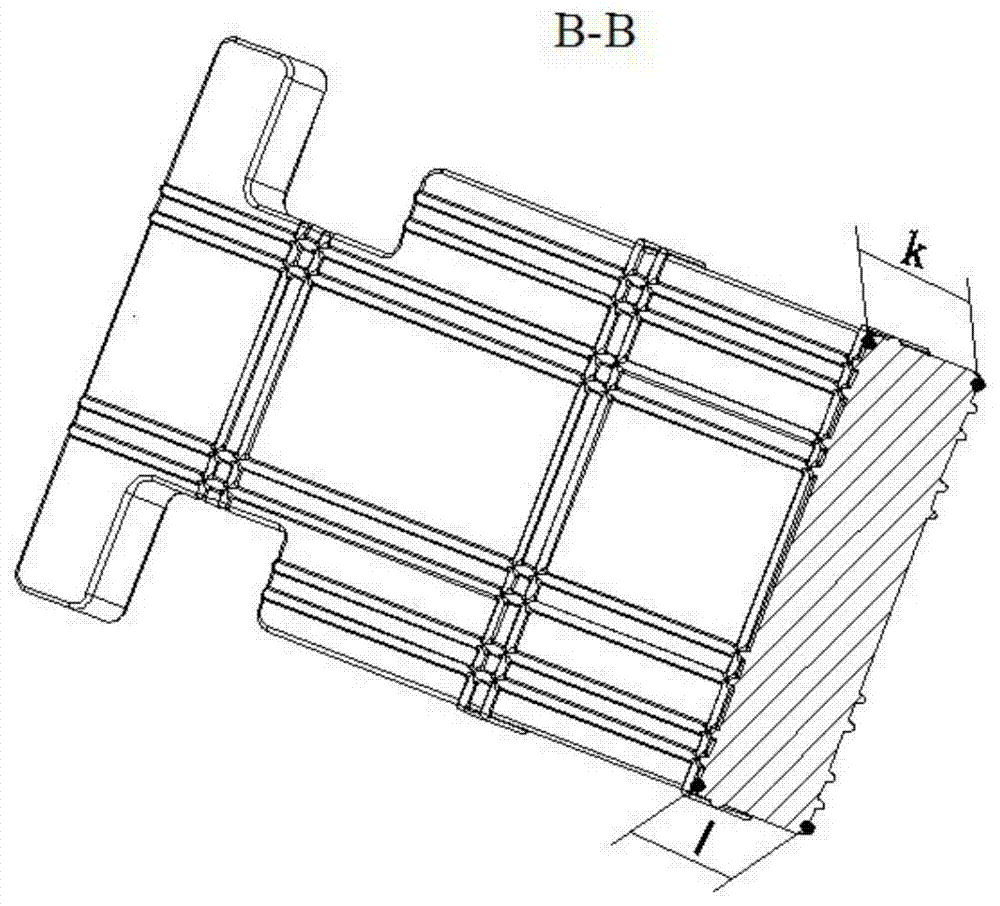

[0041] Step 1) Design a simulation sample of a thick blade casting, such as figure 1 As shown, the simulated sample of the designed thick blade core has a structure size similar to that of the actual thick blade core, and the material characteristics are the same, and the thick blade core can be directly accurately measured in the three directions of X, Y, and Z in each state. For dimension measurement, several measurement points are designed on the analog sample, and these points are accurately marked by the scale line 1;

[0042] Step 2) as in Figure 11 and Figure 12 As shown, the thick blade core mold and the thick blade outer mold are designed and manufactured. The dimensional tolerance of the designed core to be measured should not exceed 0.03mm. The designed thick blade simulation core mold and simulation The external mol...

Embodiment 2

[0049] Embodiment 2, a method for measuring the shrinkage rate of the hollow casting of thin blades, specifically includes the following steps:

[0050] Step 1) Design a simulation sample of a thin blade casting, such as Figure 13 As shown, the simulated sample of the designed thin blade core has a structure size similar to that of the actual thin blade core, and the material characteristics are the same, and the thin blade core can be directly accurately measured in the three directions of X, Y, and Z in each state. For dimension measurement, several measurement points are designed on the analog sample, and these points are accurately marked by the scale line 1;

[0051] Step 2) as in Figure 23 and Figure 24 As shown, the thin blade core mold and thin blade external mold are designed and manufactured. The dimensional tolerance of the designed core to be measured should not exceed 0.03mm. The designed thin blade simulation core mold and simulation The external mold stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com