No-pickling cold drawing processing method of steel wire

A processing method, no pickling technology, used in metal processing equipment, manufacturing tools, grinding machines, etc., can solve problems such as operator injury and environmental pollution, and achieve the effect of eliminating pollution and eliminating bodily harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following specific examples further illustrate the present invention.

[0015] Steel wire of the present invention does not have pickling cold drawing processing method, it comprises the following steps:

[0016] (1) Select a steel wire rope with an outer diameter of φ5.50mm and first spheroidize and anneal;

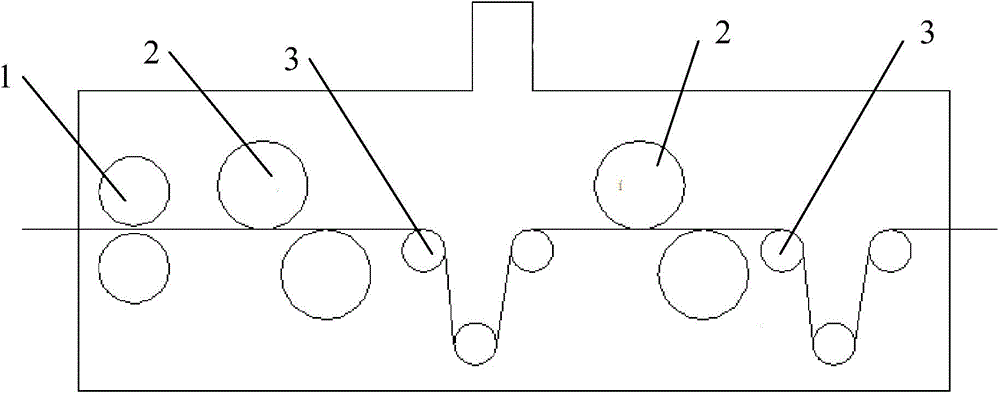

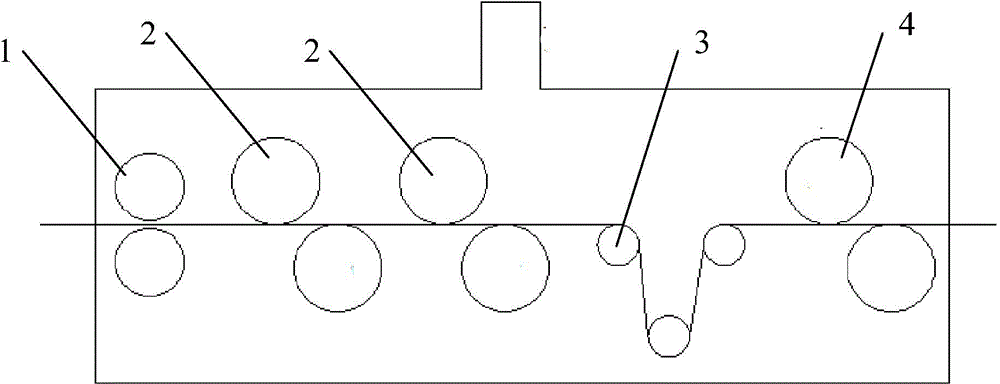

[0017] (2) The first cold drawing: cold drawing is carried out through a joint drawing machine, and the steel wire rope passes through a set of guide wheels for straightening the steel wire rope after entering. Steel brush 2, a group of rollers 3, another group of steel brushes 2 with a dislocation distribution up and down and at 45 degrees to the horizontal plane, and another group of rollers 3; then pass through four groups of inner holes with sizes of φ4.70mm and φ4 .16mm, φ3.66mm, φ3.26mm rolling head through the mold, so that the final steel wire rope with an outer diameter of φ3.26mm; the wire speed of the steel wire rope passing through the puller is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com