Flat-end milling cutter

An end mill and flat head technology, applied in the field of flat head end mills, can solve problems such as unreasonable design, low processing efficiency, tool breakage, etc., and achieve the effects of good surface roughness, improved product quality, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

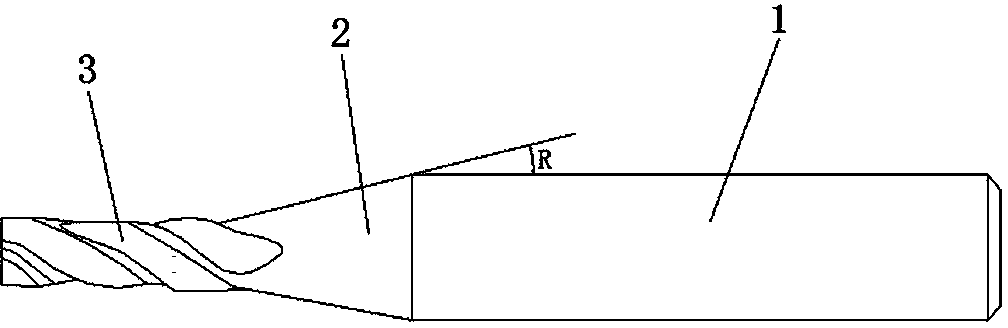

[0010] Such as figure 1 As shown, the flat head end mill includes a handle part 1, a neck 2 and a flat head cutter head 3, and the neck 2 is arranged between the handle part 1 and the flat head cutter head 3, and the neck 2 One end of the neck is fixedly welded with the handle part 1, and the other end of the neck 2 is fixedly welded with the flat-headed cutter head 3, and a transition angle is set between the neck 2 and the handle part 1, wherein the handle part and the neck are both It is made of metal material and is designed in such a way that the maximum processing hardness of the milling cutter can reach 52HRC, and the flat head 3 is a hard aluminum alloy flat head. Wherein, the flat head type cutter head 3 is provided with an ALC coating; the transition angle R is 10 to 15 degrees. In this embodiment, the transition angle R is 14 degrees. , so the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com