Large plastic deformation method for achieving titanium alloy low-temperature superplasticity

A technology of severe plastic deformation and superplasticity, applied in the direction of metal extrusion dies, etc., can solve problems such as wasting time, and achieve the effects of broadening the application field, reducing labor intensity, and widening the extrusion deformation of channel bends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

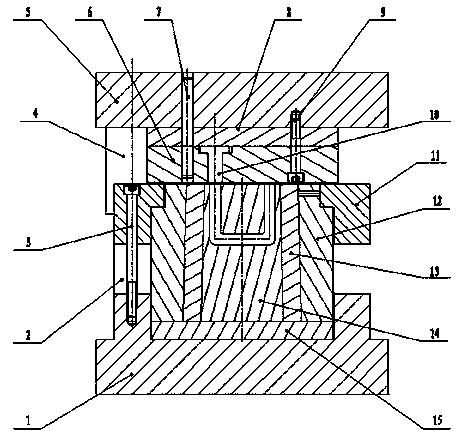

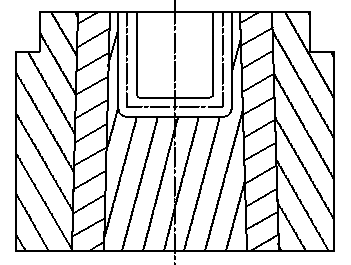

[0016] From figure 1 Shown mold assembly drawing of the present invention, figure 2 As can be seen from the details of extrusion channel design skills in the prestressed combined die structure, the present invention mainly includes 1. Lower formwork 2. Guide pillar 3. Hexagon socket head screw 4. Guide sleeve 5. Upper formwork 6. Convex die fixing plate 7 .Positioning cylindrical pin 8 punch backing plate 9. Hexagon socket screw 10. Punch 11. Die plate 12. Second layer of die pressing sleeve 13. First layer of die pressing sleeve 14. Die die 15. Die die pad, etc. composition. In the extrusion process, the materials used in the extrusion experiment are first cut by wire cutting, and then processed into a sample with a diameter of 12mm and a length of 40mm by cutting. A continuous equal-channel angle extrusion die. After preheating the extrusion part and the mold, the extrusion starts due to the limited length of the punch. When the extrusion part completely enters the chan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap