Electrospark trimming device for metal binding agent superabrasive formed grinding wheel for sawtooth processing

A technology of metal bond and superabrasive, which is applied in the direction of abrasive surface adjustment devices, accessory devices, electric processing equipment, etc., can solve the problems of uneven loss of electrodes, increase of working hours and costs, and loss of original shape of electrodes, etc., to achieve The effect of wide processing range, avoiding damage and avoiding arc discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

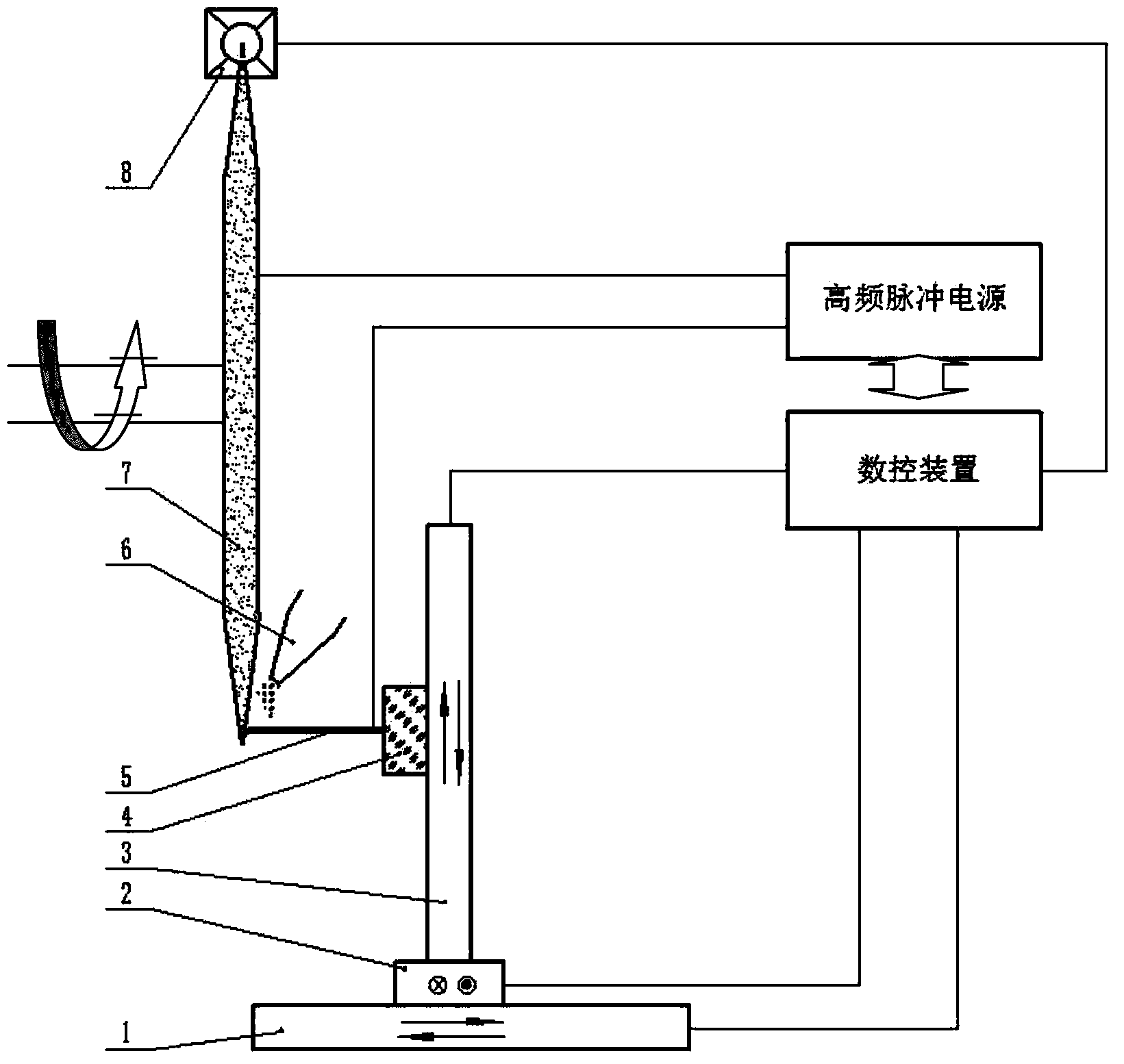

[0029] Such as figure 1 As shown, the overall device of the present invention includes an X-direction numerically controlled movement module 1, a Y-direction numerically controlled movement module 2, a Z-direction numerically controlled movement module 3, an insulating fixture 4, a tool electrode 5, a CCD on-line detection device 8, and a numerically controlled operation devices and high-frequency power supplies.

[0030] CNC movement module 1 in the X direction, NC movement module 2 in the Y direction, and NC movement module 3 in the Z direction are all connected to the numerical control device, and the CCD online detection device 8 detects the shape of the end face of the grinding wheel and transmits the data information to the numerical control device. The numerical control system real-time Adjust processing status. The tool electrode 5 is mounted on the insulating jig 4 and connected to the negative pole of the high-frequency pulse power supply. The grinding wheel 7 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com