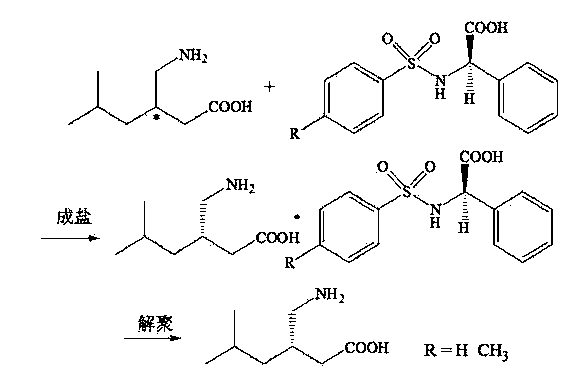

Chemical resolution preparation method of S-configuration pregabalin

A pregabalin and chemical separation technology, applied in the S-configuration pregabalin separation process and compound preparation field, to achieve the effects of less environmental pollution, high optical purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Salt forming process

[0023] In a 50mL clean three-neck flask, add 5.50g of p-toluenesulfonamido-D-phenylglycine and 40mL of isopropanol solution with a volume ratio of 3%, and heat to dissolve; add 2.40g of pregabalin racemate, and keep warm at a slow speed Stir for 0.5h, cool down naturally at 30-35°C, and crystallize for 4h. Suction filtration, transfer the obtained solid to 15 mL of isopropanol solution with a volume ratio of 3%, keep stirring at 50°C for 1h, cool to 30°C, crystallize for 1h, suction filtration, and dry to obtain 3.0g of S-pregabalin and p- Methylbenzenesulfonamide-D-phenylglycinate complex.

[0024] (2), depolymerization process

[0025] Suspend 3.0 g of the above-mentioned salt complex in 15 mL of deionized water, adjust pH = 0.5-1 with 10% hydrochloric acid, stir at room temperature for 3 h, filter, wash with 4 mL of water, dry, and recover the resolving agent p-toluenesulfonamide -D-phenylglycine 2.0 g. Adjust the pH = 6 to 6.5 with 20%...

Embodiment 2

[0027] (1) Salt forming process

[0028] In a 100mL clean three-necked flask, add 5.0g of benzenesulfonamide-D-phenylglycine and 40mL of 3% isopropanol solution by volume, heat to dissolve; add 2.40g of pregabalin racemate, keep warm and stir slowly for 0.5h , natural cooling 30 ~ 35 ℃, crystallization 6h. Suction filtration, the obtained solid was transferred to 30 mL of isopropanol solution with a volume ratio of 3%, kept stirring at 50°C for 2h, cooled to 30°C, crystallized for 3h, suction filtration, and dried to obtain 2.80g of S-pregabalin and benzene Sulfonamide-D-phenylglycinate complex.

[0029] (2), depolymerization process

[0030]Suspend 2.80 g of the above salt complex in 15 mL of deionized water, adjust pH = 0.5-1 with 10% hydrochloric acid, stir at room temperature for 3 h, filter, wash with 5 mL of water, dry, and recover the resolving agent benzenesulfonamide group-D- Phenylglycine 1.8g. Use 10% sodium hydroxide to adjust pH = 6 to 6.5. Concentrate 8 mL o...

Embodiment 3

[0032] (1) Salt forming process

[0033] In a 50mL clean three-neck flask, add 5.50g of p-toluenesulfonamido-D-phenylglycine and 45mL of isopropanol solution with a volume ratio of 3%, and heat to dissolve; add 2.40g of pregabalin racemate, and keep warm at a slow speed Stir for 0.5h, cool down naturally at 30-35°C, and crystallize for 6h. Suction filtration, the obtained solid was transferred to 15 mL of isopropanol solution with a volume ratio of 3%, kept stirring at 50°C for 2h, cooled to 30°C, crystallized for 2h, suction filtration, and drying to obtain 3.10g of S-pregabalin and para Methylbenzenesulfonamide-D-phenylglycinate complex.

[0034] (2), depolymerization process

[0035] Dissolve 3.10 g of the above-mentioned salt complex in 20 mL of 50% methanol solution by volume, adjust the pH = 6.5-7 with ammonia water, stir at room temperature for 3 h, cool down to 0 ° C, keep warm overnight, filter, wash with 2 mL of cold water, and dry to obtain White S-pregabalin 0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com