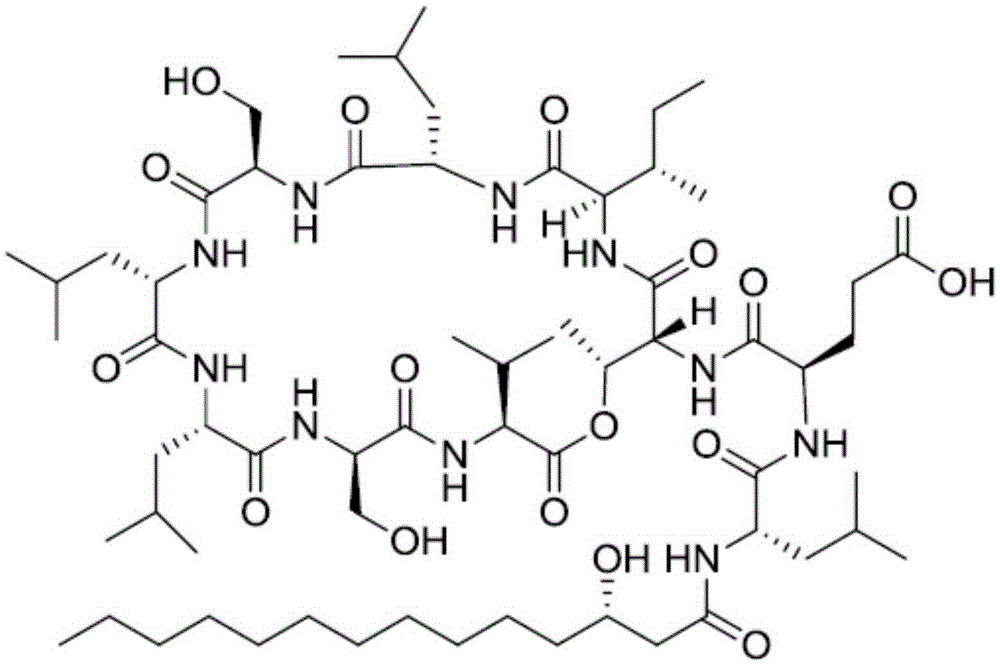

A kind of solid phase synthesis method of cyclic lipopeptide orfamide A

A technology of solid-phase synthesis and cyclic ester peptides, which is applied to the preparation methods of peptides, chemical instruments and methods, peptides, etc., and can solve the problems that there is no artificial synthesis of OrfamideA.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

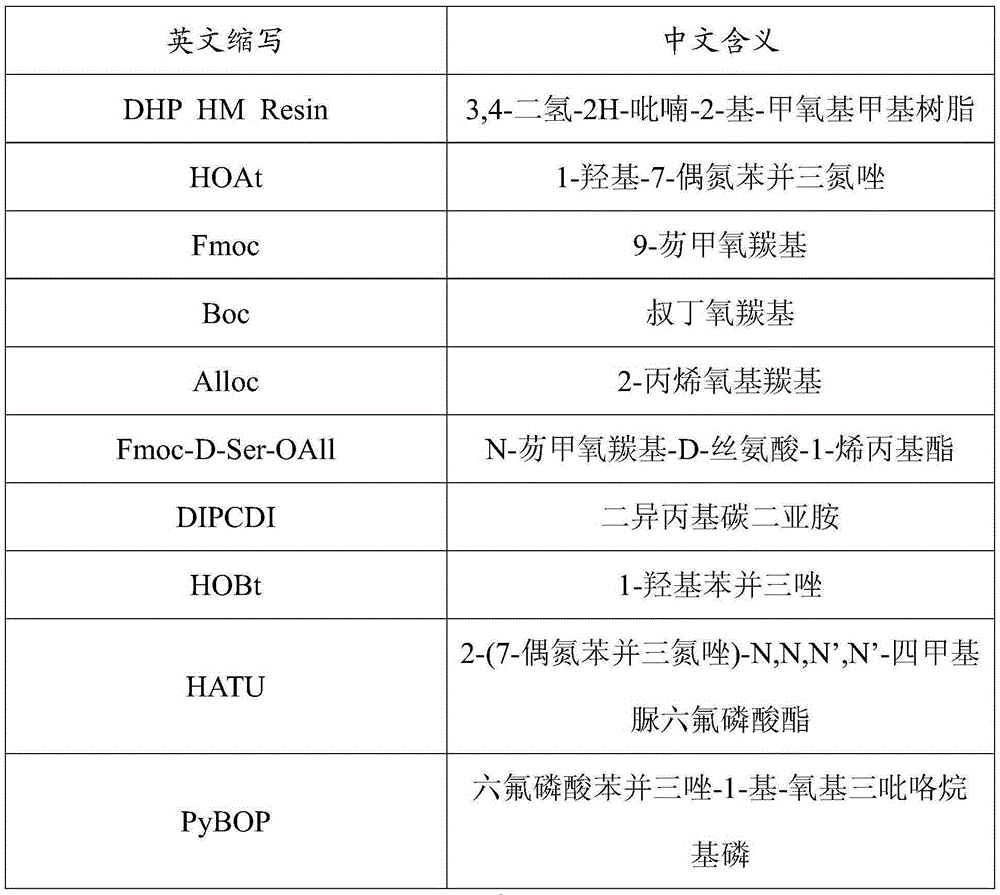

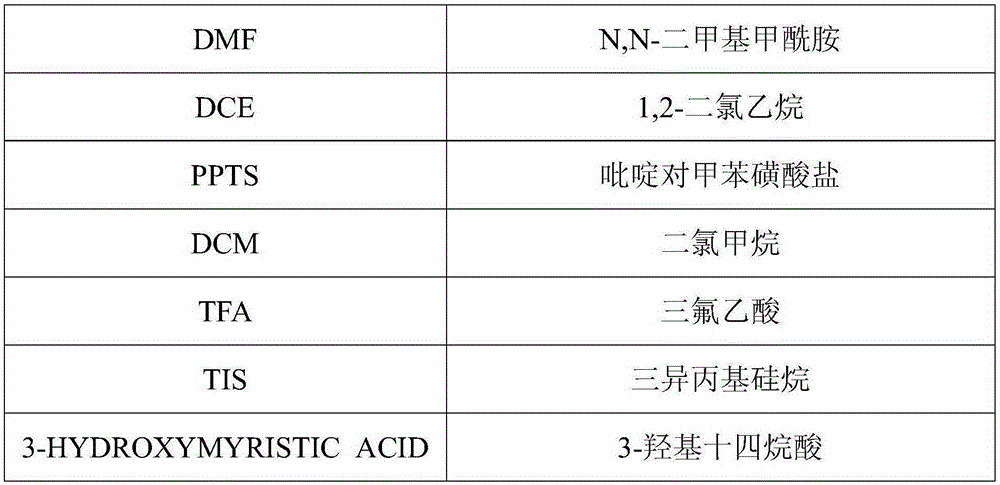

[0026] Embodiment 1: the preparation of the Fmoc-D-Ser(Resin)-OAll whose degree of substitution is 0.2mmol / g

[0027] Weigh 100g (100mmol) of DHPHM resin with a substitution degree of 1.0mmol / g, add it to the solid-phase reaction column, wash it twice with DCE, and swell the resin with DCE for 60 minutes, take 21.9g Fmoc-D-Ser-OAll (60mmol) and 7.5gPPTS (30mmol) were dissolved in 200ml DCM solution, added to the resin, and reacted at 80°C for 5h under the protection of nitrogen. Cool and filter, wash with DMF, DCM, and Hexane three times, and dry. The detected substitution degree is 0.205mmol / g.

Embodiment 2

[0028] Embodiment 2: the preparation of the Fmoc-D-Ser(Resin)-OAll whose degree of substitution is 0.5mmol / g

[0029] Weigh 100g (100mmol) of DHPHM resin with a substitution degree of 1.0mmol / g, add it to a solid-phase reaction column, wash it twice with DCE, and swell the resin with DCE for 60 minutes, take 54.7g Fmoc-D-Ser-OAll (150mmol) and 18.8gPPTS (75mmol) were dissolved in 200ml DCM solution, added to the resin, and reacted at 80°C for 5h under the protection of nitrogen. Cool and filter, wash with DMF, DCM, and Hexane three times, and dry. The detection degree of substitution is 0.500 mmol / g.

Embodiment 3

[0030] Embodiment 3: the preparation of the Fmoc-D-Ser(Resin)-OAll that the degree of substitution is 0.3mmol / g

[0031] Weigh 100g (100mmol) of DHPHM resin with a substitution degree of 1.0mmol / g, add it to the solid-phase reaction column, wash it twice with DCE, and swell the resin with DCE for 60 minutes, take 32.8g Fmoc-D-Ser-OAll (90mmol) and 11.3gPPTS (45mmol) were dissolved in 200ml DCM solution, added to the resin, and reacted at 80°C for 5h under the protection of nitrogen. After cooling and filtering, washing with DMF, DCM and Hexane three times respectively, and drying, the detected substitution degree was 0.302 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com