Far infrared ray transmitting composite material and preparation method thereof

A composite material and far-infrared technology, applied in the direction of instruments, optics, optical components, etc., can solve the problems of poor compatibility of inorganic compound crystals, low infrared light transmittance, no practical value, etc., and achieve excellent physical and mechanical performance, high transmittance of far-infrared light, and the effect of maintaining physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

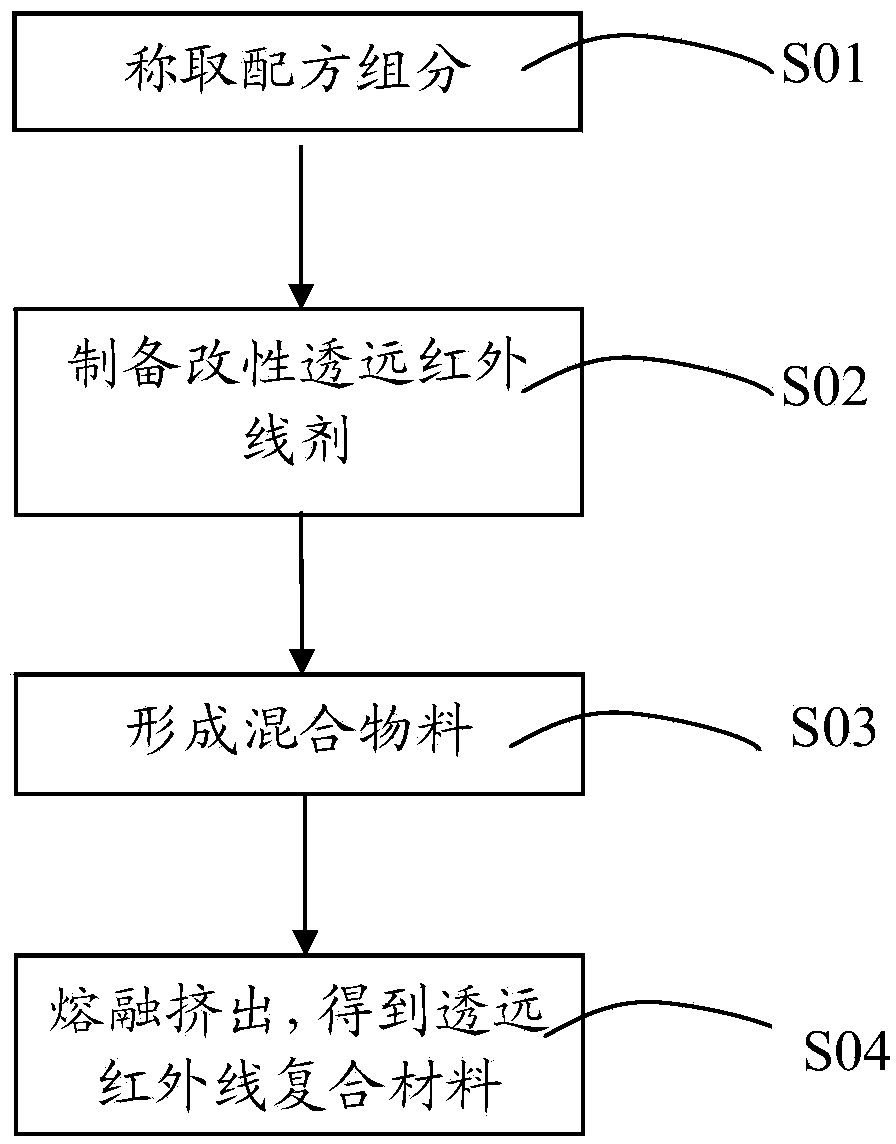

[0035] Correspondingly, the embodiment of the present invention provides the preparation method of the above-mentioned far-infrared ray-transmitting composite material, and the process flow chart of the method is as follows figure 1 shown, including the following steps:

[0036] S01, weighing formula components: weigh each component according to the above-mentioned far-infrared-transmitting composite material formula;

[0037] S02, obtaining the above-mentioned modified infrared-transmitting agent;

[0038] S03, obtaining the far-infrared-transmitting composite material: performing mixing and compounding treatment on the above-mentioned polyethylene and the above-mentioned modified infrared-transmitting agent, and then melt-extruding to obtain the above-mentioned far-infrared-transmitting composite material;

[0039] Specifically, in the above step S01, use an electronic scale (with an accuracy of 1.0%) to weigh the above-mentioned polyethylene and the modified infrared-trans...

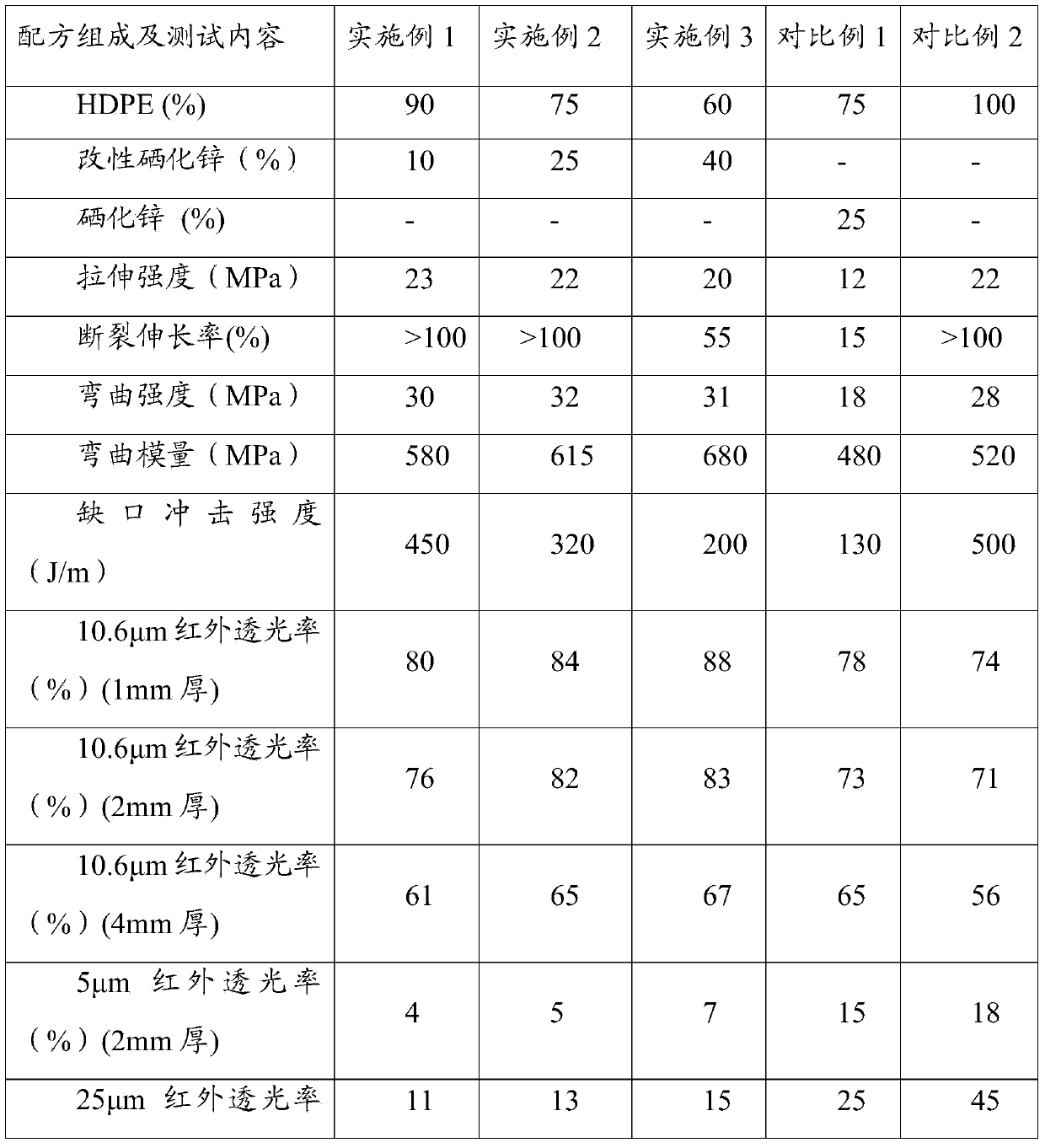

Embodiment 1

[0053] A kind of penetrating far-infrared composite material, comprises the formula component of following percentage by weight:

[0054] HDPE 90%,

[0055] Modified infrared agent 10%;

[0056] Wherein, the modified infrared-transmitting agent includes the following formula components in weight percent:

[0057] Epoxy resin E44 6%,

[0059] Epoxy curing agent T31 1%.

[0060] The preparation method of this far-infrared composite material is as follows:

[0061] S11, weighing the formula components: weighing each component according to the formula of the above-mentioned far-infrared-transmitting composite material;

[0062] S12, preparing modified zinc selenide: sequentially disperse the epoxy resin E44 and zinc selenide weighed in step S11 in pure water, and mechanically stir for 6 minutes; then add T31, and mechanically stir for 2 hours at a constant temperature of 80°C; Filter out the modified zinc selenide solid with a particle size of 3 μ...

Embodiment 2

[0066] A kind of penetrating far-infrared composite material, comprises the formula component of following percentage by weight:

[0067] HDPE 75%,

[0068] Modified infrared agent 25%;

[0069] Wherein, the modified infrared-transmitting agent includes the following formula components in weight percent:

[0070] Epoxy resin E44 12%,

[0072] Epoxy curing agent T31 1%.

[0073] The preparation method of this far-infrared composite material is as follows:

[0074] S21, weighing the formula components: weighing each component according to the formula of the above-mentioned far-infrared-transmitting composite material;

[0075] S22, preparing modified zinc selenide: sequentially disperse the epoxy resin E44 and zinc selenide weighed in step S21 in pure water, and mechanically stir for 12 minutes; then add T31, and mechanically stir for 3 hours at a constant temperature of 80°C; Filter out the modified zinc selenide solid with a particle size of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com