Method and device for detecting molten silicon liquid level of monocrystalline silicon crystal pulling furnace

A liquid level detection and measurement device technology, which is applied in the direction of self-melt pulling method, single crystal growth, chemical instruments and methods, etc., can solve the problems that cannot be applied to the liquid level detection system, and achieve the effect of improving the quality of crystal pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

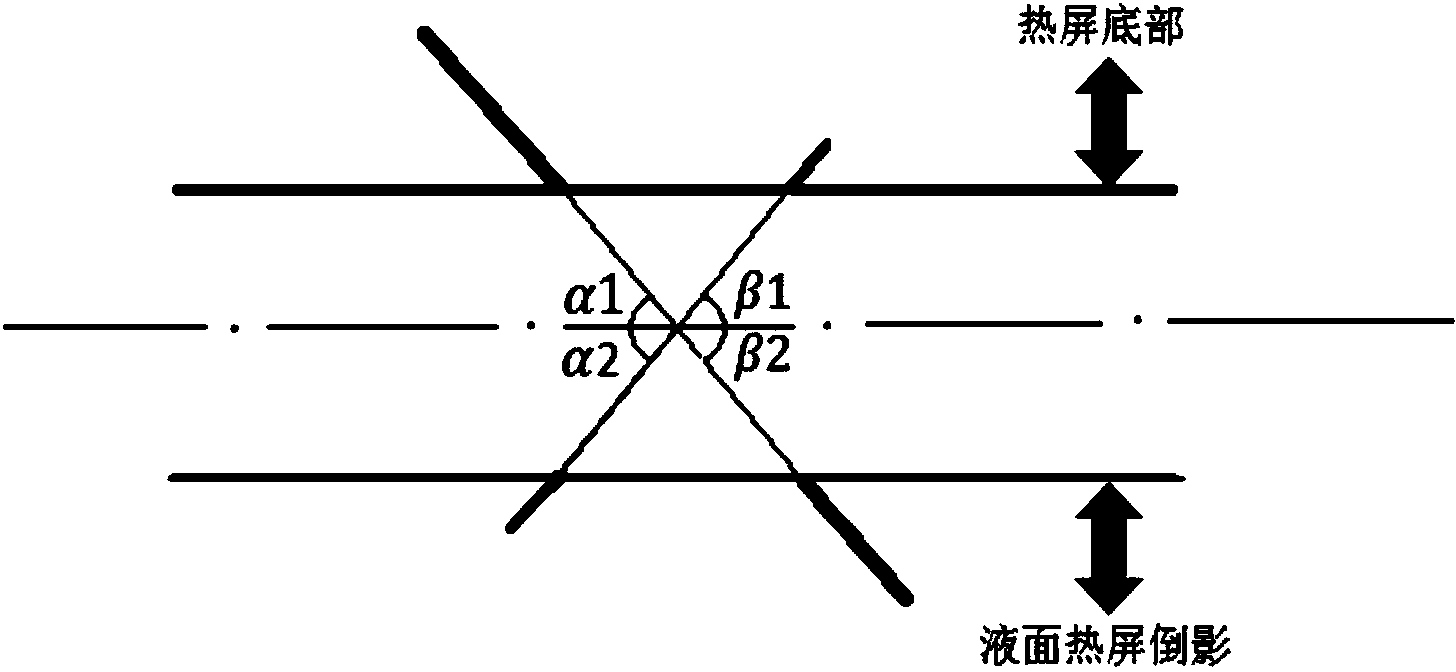

[0036] The triangular displacement measurement method is named because the incident light and the reflected light form a triangle. Its principle is to emit a beam of light from the light source to the surface of the measured object, and observe the reflected light through imaging in another direction and position. The position of the point, so that the displacement of the surface of the measured object can be obtained.

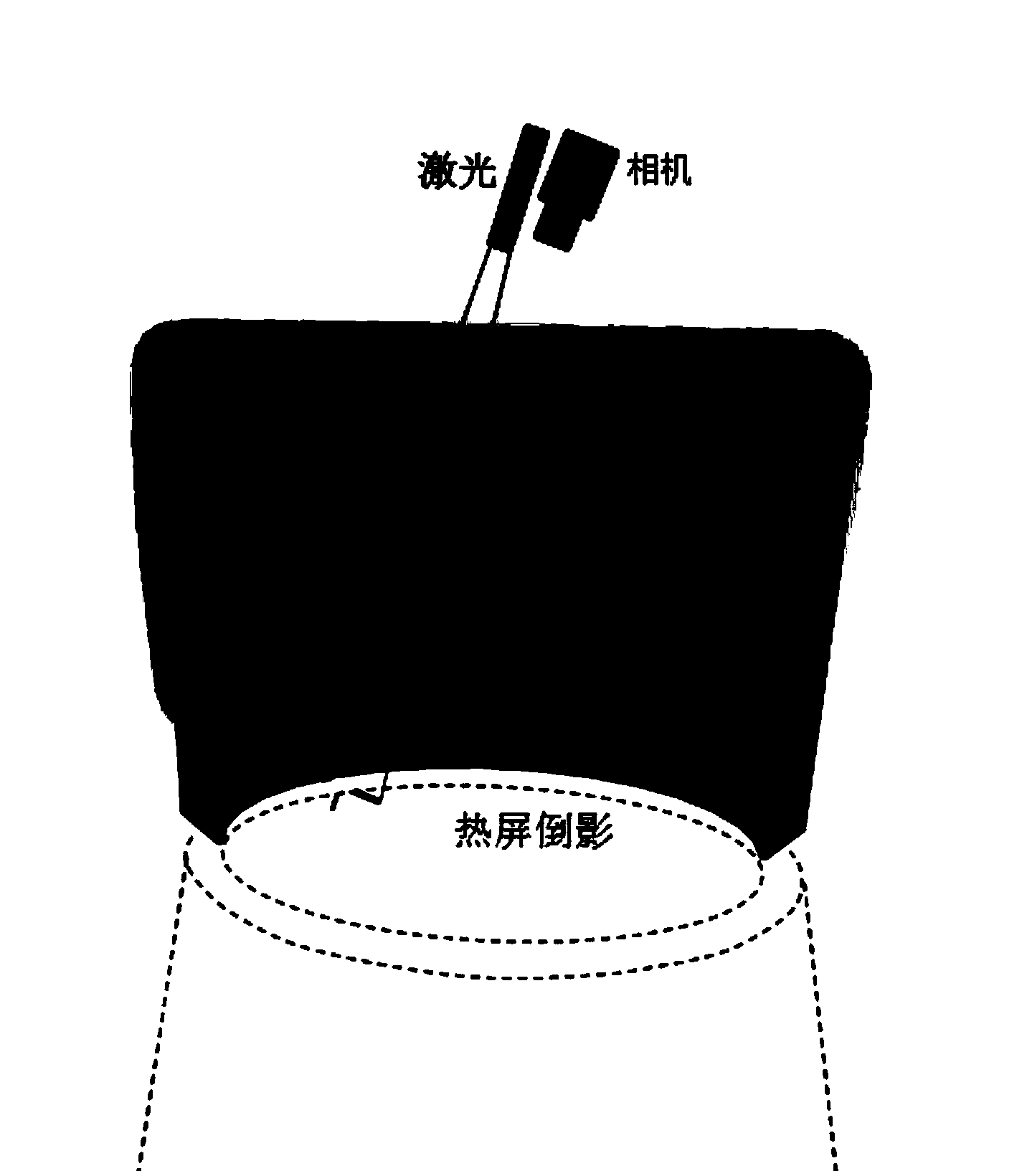

[0037] see Figure 1 to Figure 6 , a method for detecting the molten silicon liquid level of a single crystal silicon crystal pulling furnace in the present invention, a line laser and a camera are installed on the observation port of the single crystal silicon furnace, and the laser beam emitted by the laser is irradiated to the heat shield of the crystal pulling furnace thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com