A kind of method for preparing phosphogypsum whiskers by secondary crystallization

A technology of phosphogypsum whiskers and secondary crystallization, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problem of short aspect ratio of phosphogypsum whiskers, difficult to succeed without pretreatment, difficult to produce, etc. The problem is to achieve the effect of good solid-liquid ratio, reasonable reaction temperature and stirring speed, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

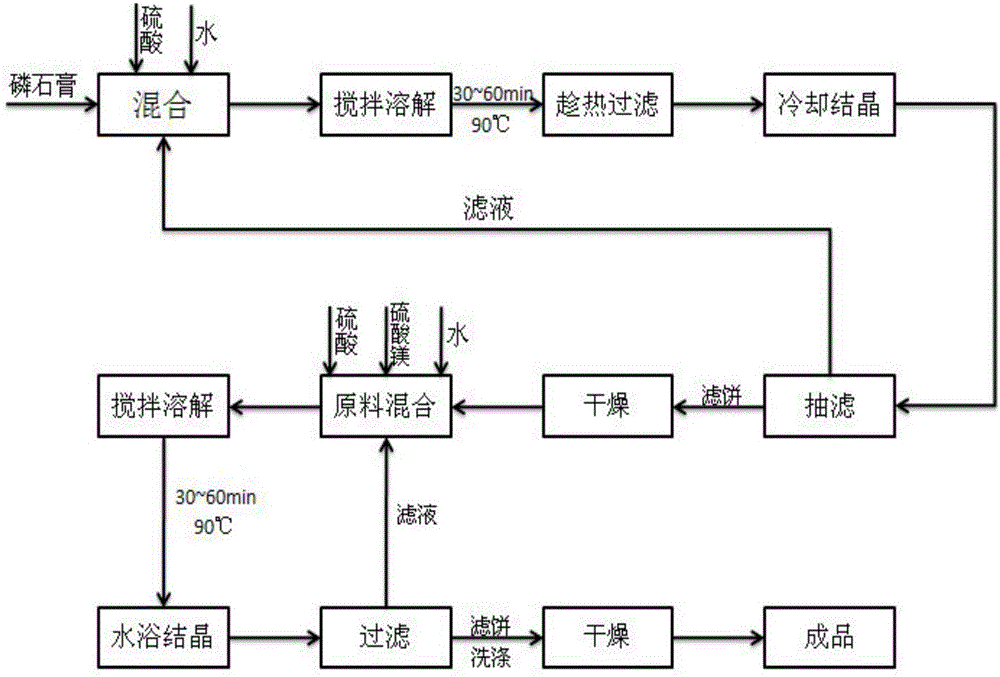

Method used

Image

Examples

Embodiment 1

[0032] (1) Primary crystallization:

[0033] Weigh 10g of dried phosphogypsum, add a sulfuric acid solution with a mass fraction of 8% according to the ratio of solid to liquid ratio 1:100, place it in a water bath with a water bath temperature of 80°C, stir and react at a speed of 250r / min, and react for 30min Finally, filter while it is hot, discard a small amount of insoluble matter, and cool the filtrate to crystallize at room temperature. After suction filtration, the filter cake is calcium sulfate dihydrate.

[0034] (2) Secondary crystallization:

[0035] Weigh 10g of calcium sulfate dihydrate obtained in one crystallization, add 8% sulfuric acid solution with a mass fraction of 8% according to the solid-to-liquid ratio of 1:100, and add 5% crystal aid magnesium sulfate, and place it in a water bath with a water bath temperature of 80°C Stir the reaction in a pot at a speed of 250r / min. After the solid is completely dissolved, keep the temperature constant for 30 minut...

Embodiment 2

[0037] (1) Primary crystallization:

[0038] Weigh 100g of dried phosphogypsum, add a sulfuric acid solution with a mass fraction of 10% according to the ratio of solid to liquid ratio 1:100, place it in a water bath with a water bath temperature of 90°C, stir and react at a speed of 250r / min, and react for 45min Finally, filter while it is hot, discard a small amount of insoluble matter, and cool the filtrate to crystallize at room temperature. After suction filtration, the filter cake is calcium sulfate dihydrate.

[0039] (2) Secondary crystallization:

[0040] Weigh 100g of calcium sulfate dihydrate obtained in one crystallization, add 10% sulfuric acid solution with a mass fraction of 10% according to the solid-to-liquid ratio of 1:100, and add 10% crystallization aid magnesium chloride, and place it in a water bath with a water bath temperature of 90°C Stirring reaction in medium temperature, rotating speed 250r / min, after the solid is completely dissolved, keep the tem...

Embodiment 3

[0042] (1) Primary crystallization:

[0043] Weigh 1000g of dried phosphogypsum, add sulfuric acid solution with a mass fraction of 15% according to the ratio of solid to liquid ratio of 1:100, put it in a water bath with a water bath temperature of 100°C, stir and react at a speed of 250r / min, and react for 60min Finally, filter while it is hot, discard a small amount of insoluble matter, and cool the filtrate to crystallize at room temperature. After suction filtration, the filter cake is calcium sulfate dihydrate.

[0044] (2) Weigh 1000g of calcium sulfate dihydrate obtained in the first crystallization, add a sulfuric acid solution with a mass fraction of 15% according to the solid-to-liquid ratio of 1:100, and add 15% crystallization aid magnesium sulfate, and place it in a water bath at a temperature of 100 Stir the reaction in a water bath at ℃, with a rotation speed of 250r / min. After the solid is completely dissolved, keep the temperature constant for 60 minutes, sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com