Method for better utilizing waste gas of turboset

A steam turbine unit and steam turbine technology, which is applied in steam applications, steam engine installations, mechanical equipment, etc., can solve problems such as affecting the benefits of power plants, and the income is not stable enough to achieve stable income, improve benefits, and ensure the effect of normal demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

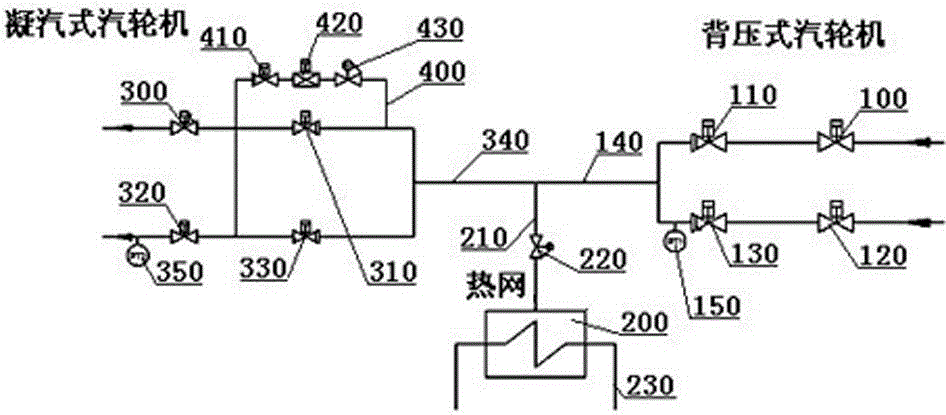

[0015] The present invention is based on the coexistence of the back pressure steam turbine and the condensing steam turbine in the power plant, the back pressure steam turbine and the condensing steam turbine coexisting in the power plant are connected through the online device, and the back pressure steam turbine and the condensing steam turbine are connected together. The exhaust steam pipe is connected at the steam inlet pipe of the heating network. The aforementioned online devices such as figure 1 As shown, it is mainly composed of an online pipeline 400 and an online shut-off valve 430, an online quick-closing regulating valve 420, and an online check valve 410 connected in series on the online pipeline 400 in sequence. One end of the online pipeline 400 is connected to the condensing steam of the condensing steam turbine. On the steam extraction pipe 340, the other end is connected to the steam inlet of the condensing steam turbine (usually the low-pressure cylinder st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com