Composite two-lip threaded lip oil seal

A thread and lip technology, which is applied in the field of double-lip structure oil seals, can solve the problems of not being able to work for a long time, lubricating oil penetration, leakage and sealing, etc., and achieve the effects of improving use value, saving material costs, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

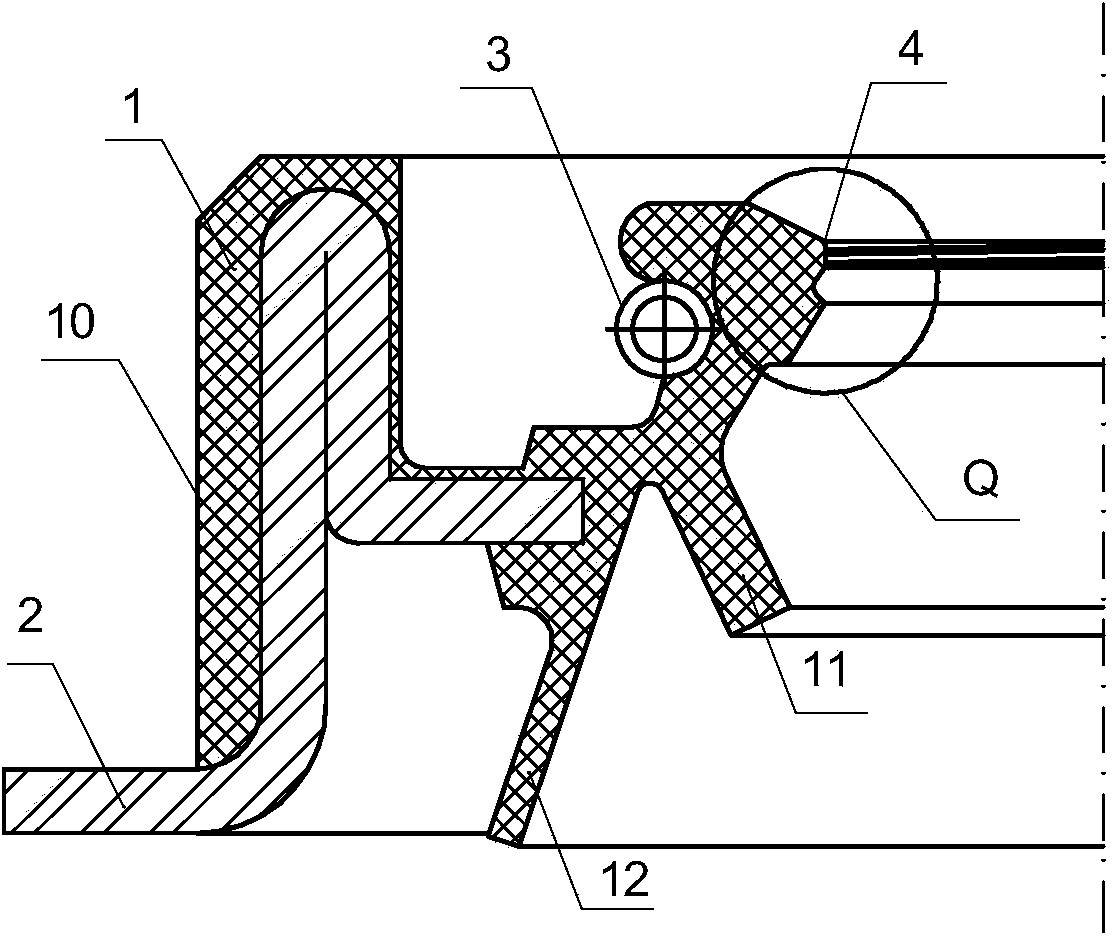

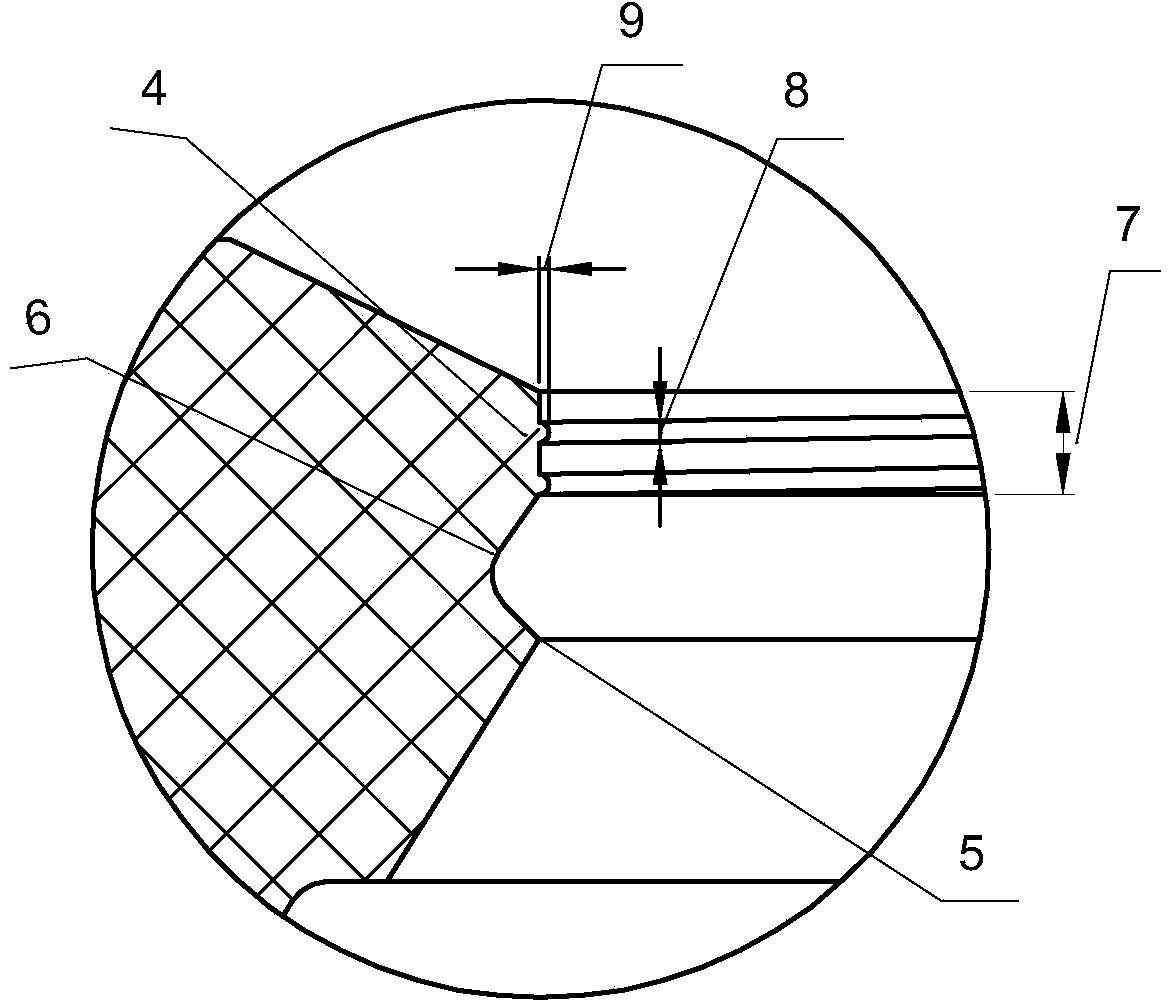

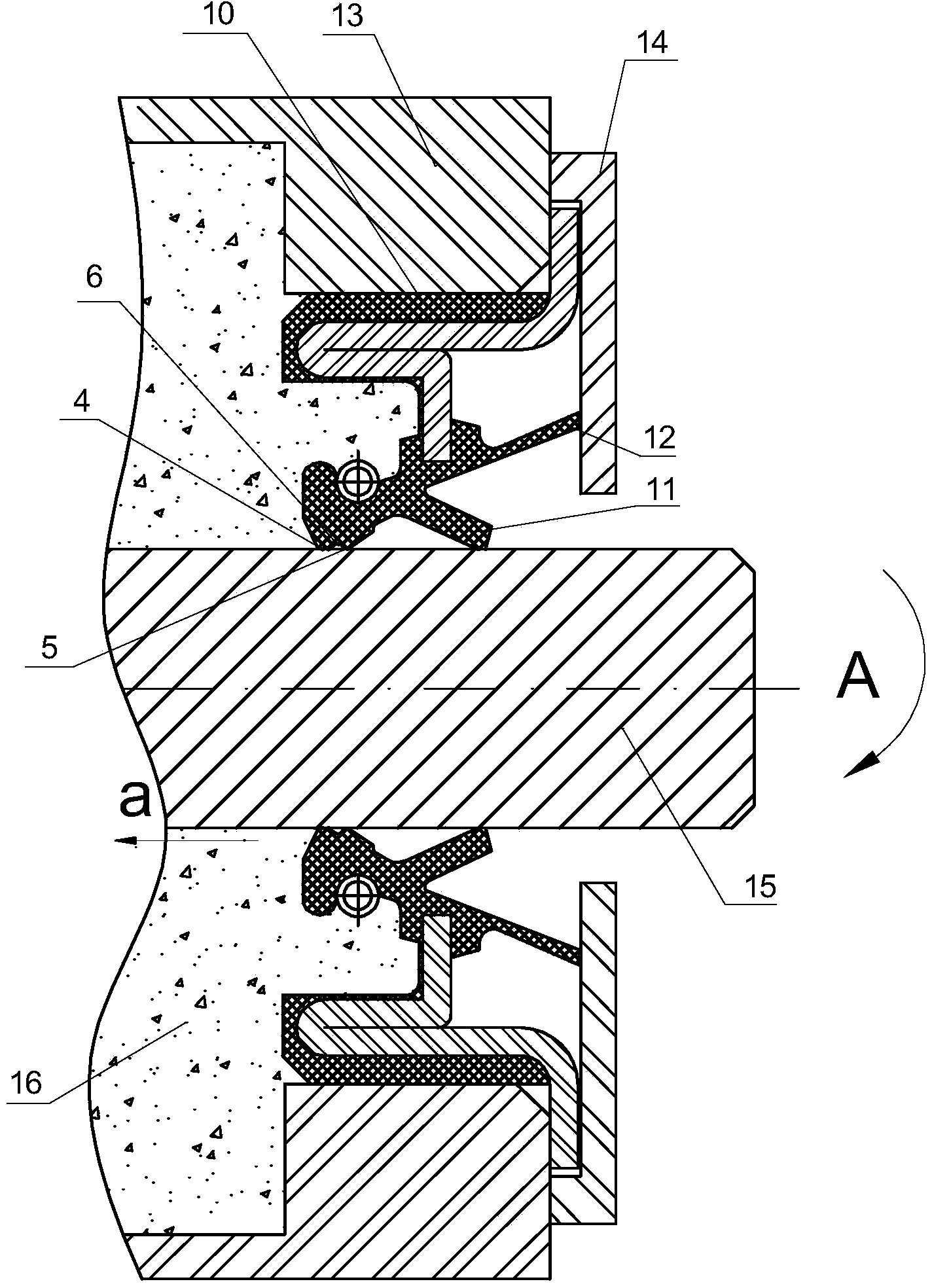

[0014] refer to Figure 1-Figure 3 , a composite double-lip threaded lip oil seal, including a metal skeleton 2 and a rubber body 1, the rubber body 1 is combined with the metal skeleton 2 through a vulcanization molding mold and process, and the outer wall of the rubber body 1 is an outer diameter matching surface 10, Interference fit with the sealing body 13, the outer diameter mating surface 10 can be a plane structure with rubber or a wave structure, or a plane structure with a metal skeleton; on the inner side of the rubber body 1, there is an interference fit with the working shaft 15 The main lip and the inner auxiliary lip 11; outside the main lip of the rubber body 1, there is a spring 3, and on the lower side of the rubber body 1, there is an outer auxiliary lip 12 that is interference fit with the end cover 14, and the inner The auxiliary lip 11 and the outer auxiliary lip 12 are dust-proof structures, and the structures of the inner auxiliary lip 11 and the outer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com