Non-standard square coil for magnetic field immunity test and calibrating method and calibrating system of non-standard square coil

A technology of calibration system and calibration method, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of reduced test accuracy, inability to carry out, and inability to guarantee the calibration accuracy of non-coils, etc., to reduce the impact of test errors on results. Impact, Avoid Bias, Guaranteed Coverage Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

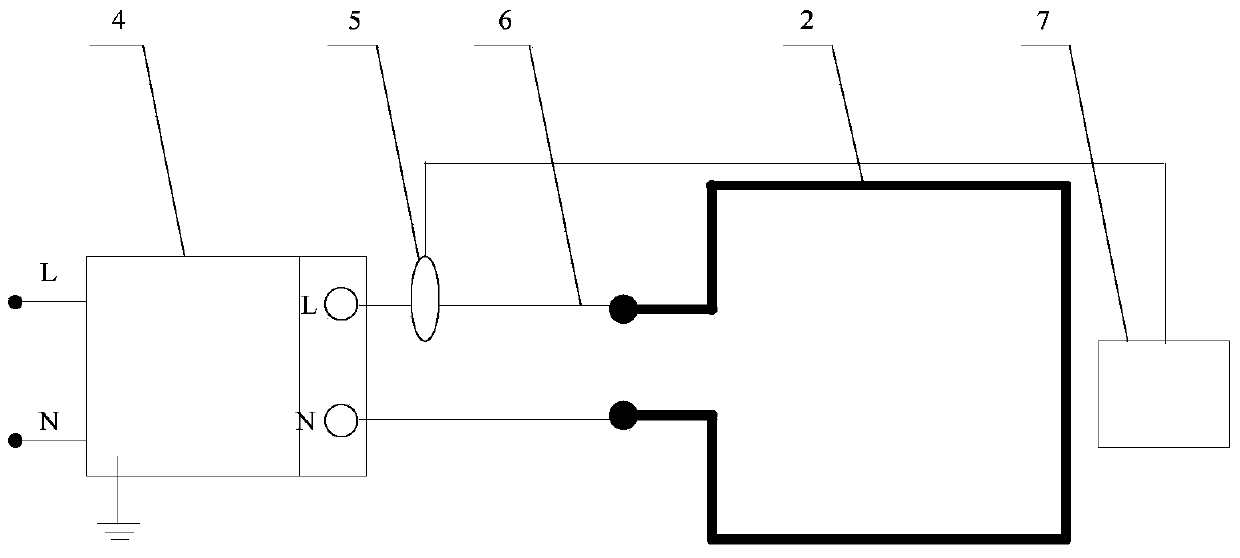

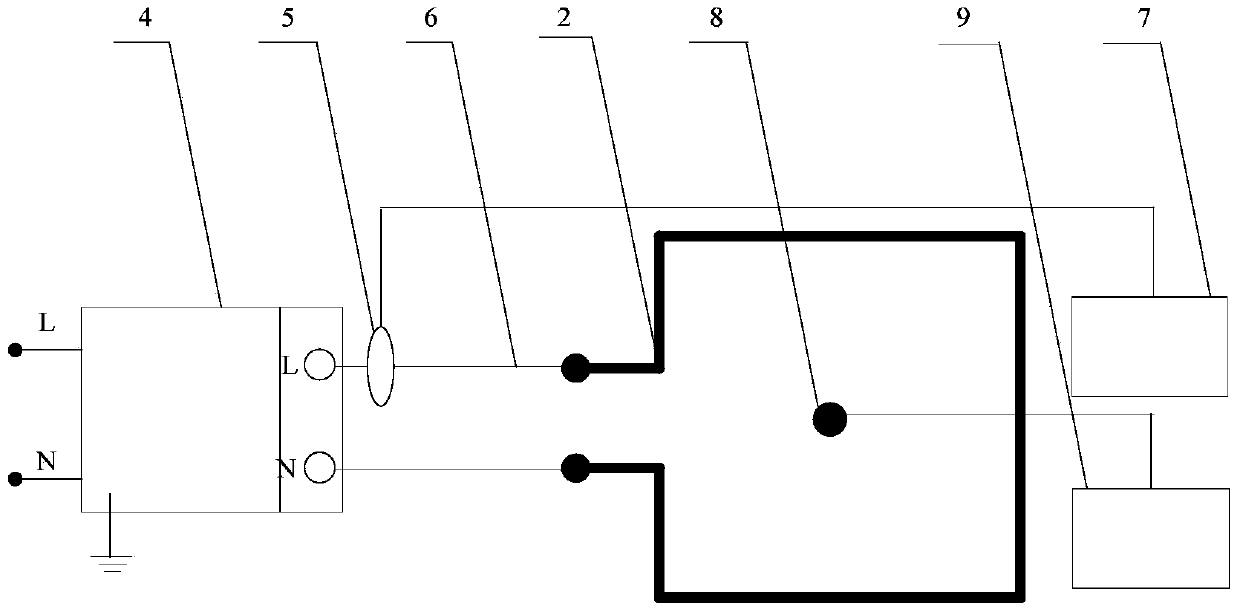

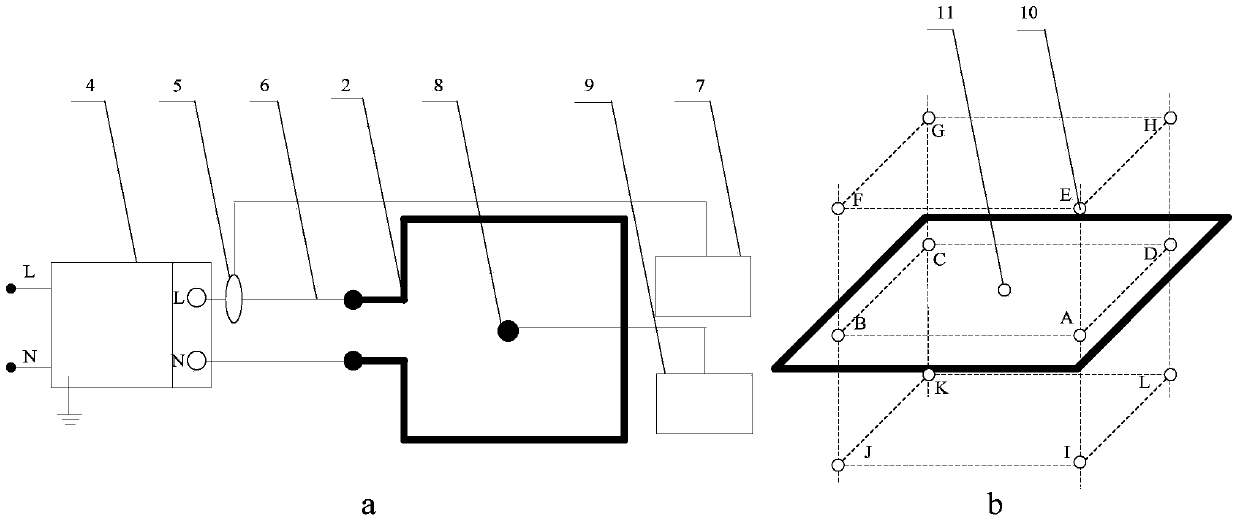

[0035] The calibration system of the non-standard square coil of the magnetic field immunity test of the present invention includes a magnetic field generation circuit, and a current monitoring circuit and / or a magnetic field detection circuit; the magnetic field generation circuit includes a current generator 4, and a The connection line 6 between the generator 4 and the non-standard square coil 2; the current monitoring circuit includes a current probe 5 arranged on the output connection line 6 of the output side of the current generator 4, and the input end is connected to the output end of the current probe 5 The oscilloscope 7; the magnetic field detection circuit includes a magnetic field probe 8 arranged in the magnetic field area formed by the non-standard square coil 2, and a magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com