Grid driving circuit and grid driving method

A gate drive circuit and drive signal technology, applied in the direction of instruments, static indicators, etc., can solve the problems of increasing the circuit area of the shift register, reducing the visible area of the display panel, increasing the production cost, etc. The effect of reducing size, simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

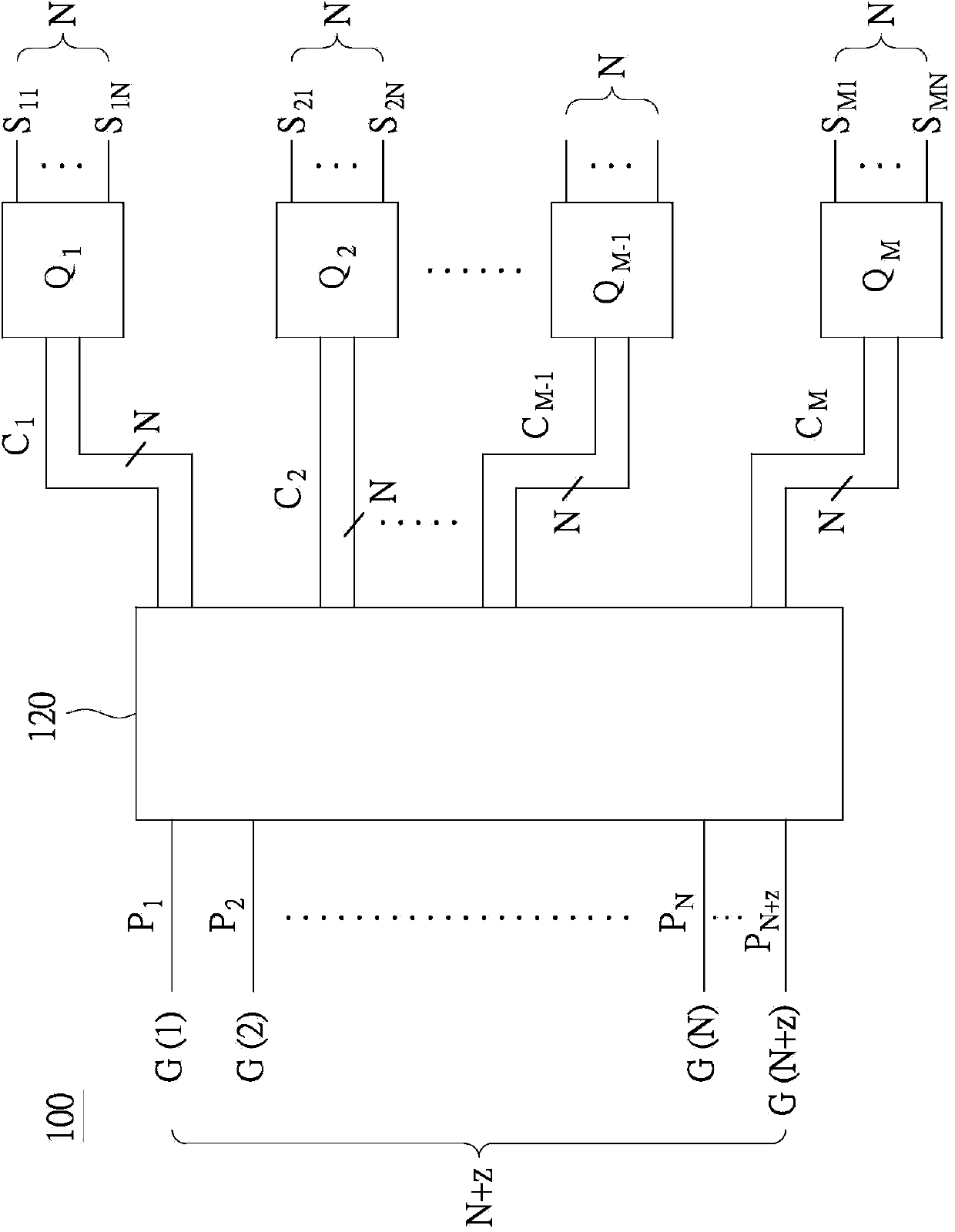

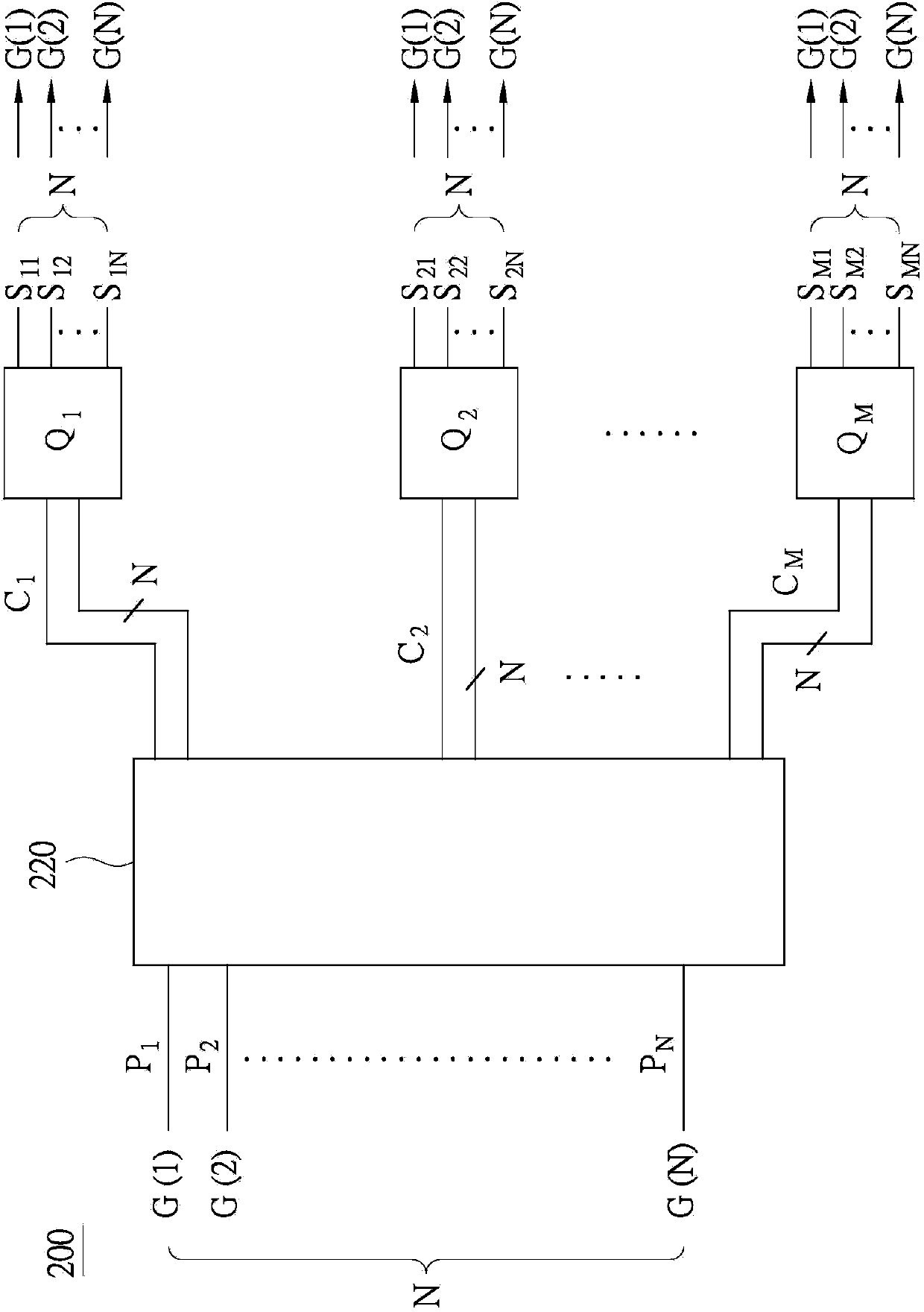

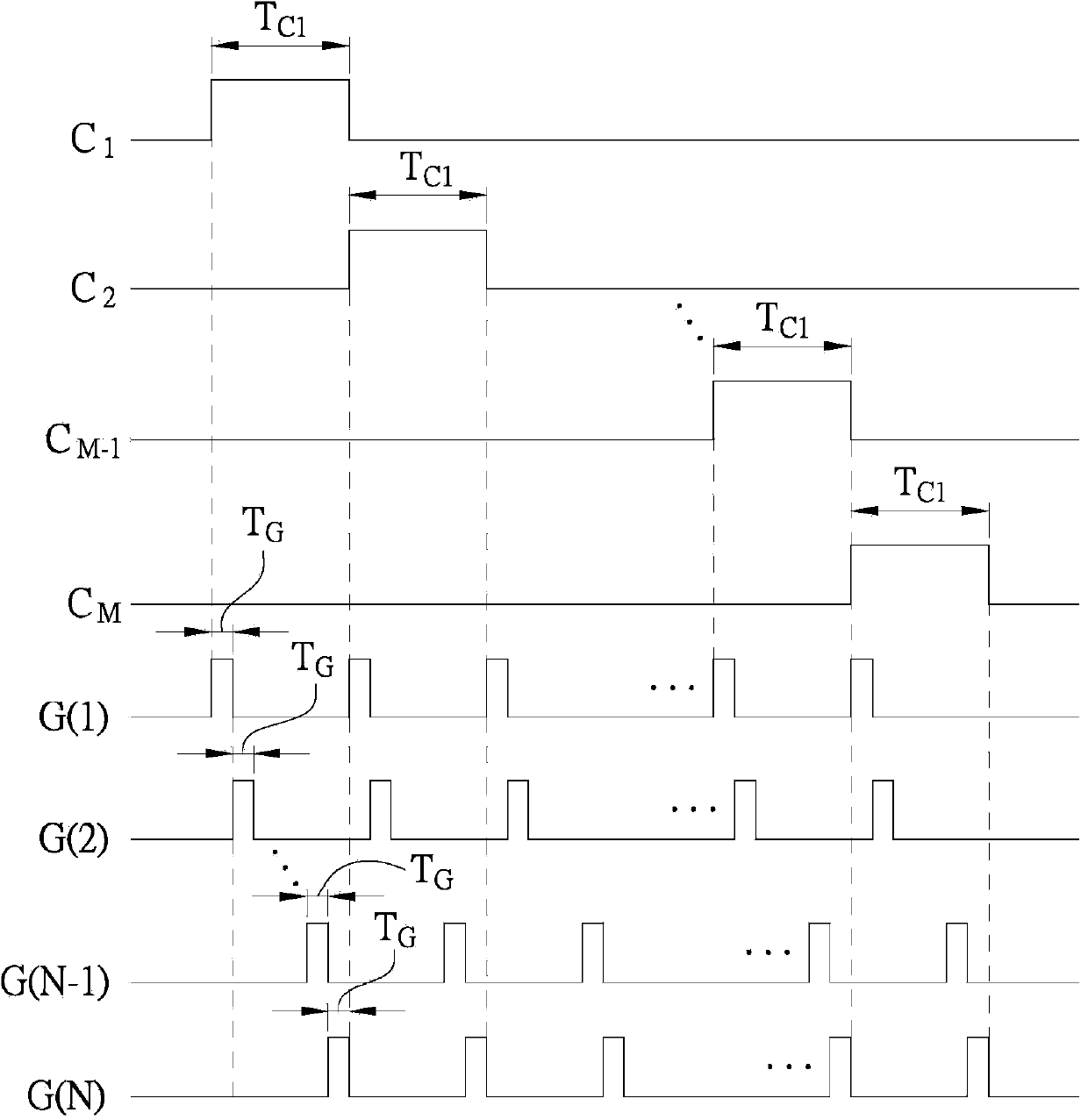

[0030] Please refer to figure 1 , figure 1 It is a schematic diagram of a gate driving circuit 100 according to an embodiment of the present invention. Such as figure 1 As shown, the gate drive circuit 100 includes at least N signal lines P 1 ,P 2 ,...,P N ,...,P N+z , M switch modules Q 1 , Q 2 ,...,Q M-1 , Q M , and the control module 120, wherein N represents the number of scan lines connected to each switch module, and z is an integer greater than or equal to zero. N+z signal lines P 1 ~P N+z It is used to transmit driving signals corresponding to the number of signal lines, that is, N+z driving signals G(1), G(2), . . . , G(N), . . . , G(N+z). Each driving signal is a periodic continuous timing signal, and the duty cycle (duty cycle) of each driving signal is 1 / (N+z).

[0031] Each switch module is electrically connected to N scanning lines S M1 ~S MN (M is the corresponding switch module). Therefore, the gate drive circuit 100 has M*N scanning lines S in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com