Passive waste heat discharge system of nuclear power station steam generator secondary side

A steam generator and passive waste heat technology, applied in steam generation, nuclear power generation, steam boilers, etc., can solve problems such as failure, unit loss of ability to discharge waste heat from the core, and inability to guarantee the safety of nuclear power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

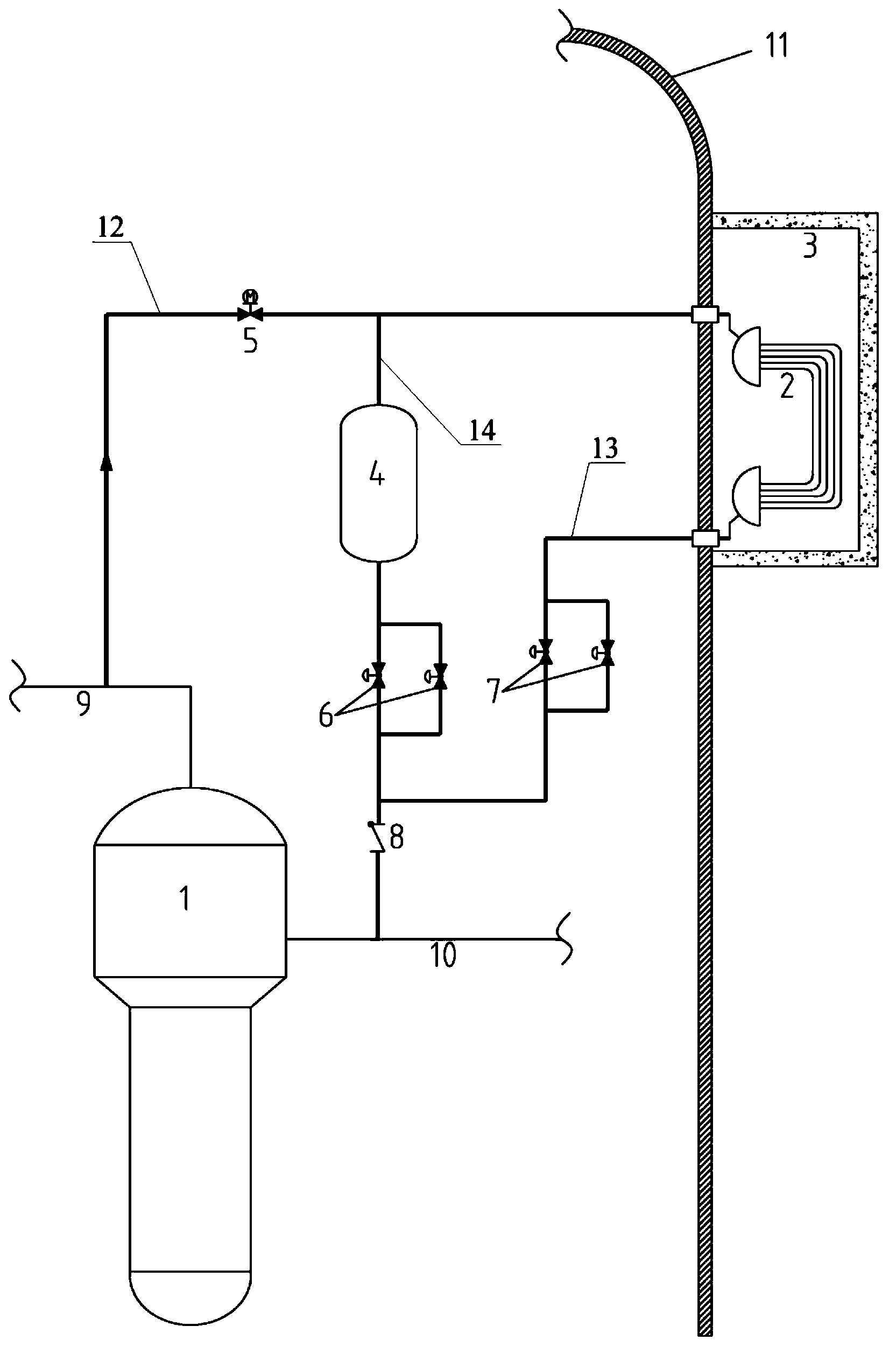

[0022] Such as figure 1 The present invention shows a passive waste heat removal system on the secondary side of a steam generator in a nuclear power plant. The waste heat removal system includes a cooling water tank 3 arranged on the periphery of a reactor containment 11 and filled with water. The containment 11 of the reactor has a cylinder The cylinder body, the cooling water tank 3 has a ring-shaped structure and is arranged at a higher position outside the containment vessel 11. The civil structure and the containment vessel are uniformly designed. The cooling water tank 3 is provided with a water replenishment structure and a drainage structure for The cooling water tank 3 drains water during replenishment and maintenance.

[0023] The heat exchanger 2 is submerged in the bottom of the cooling water tank 3, and water inlets and outlets are arranged on the upper and lower heads of the heat exchanger.

[0024] One end of the first waste heat discharge pipeline 12 passes t...

Embodiment 2

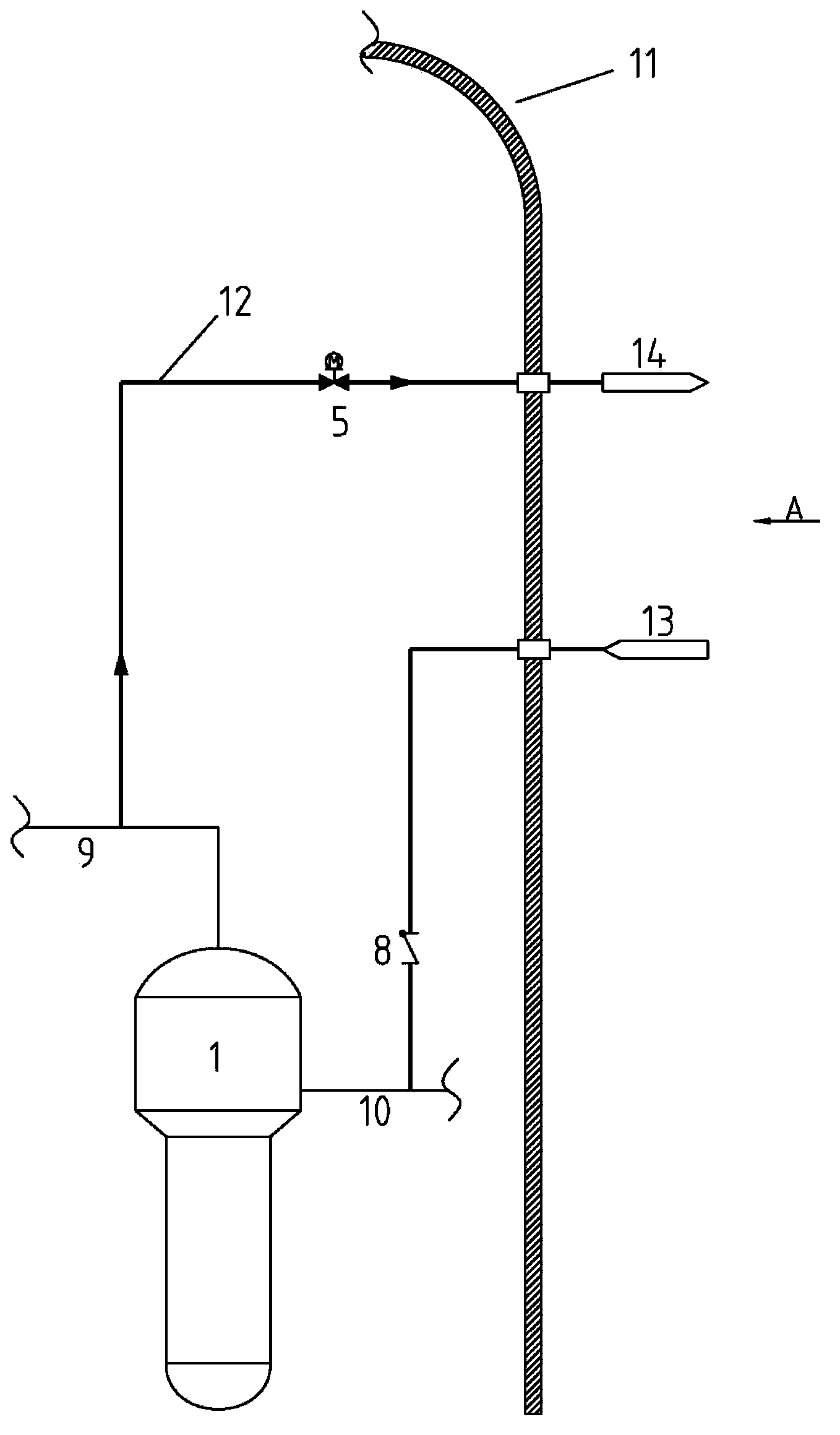

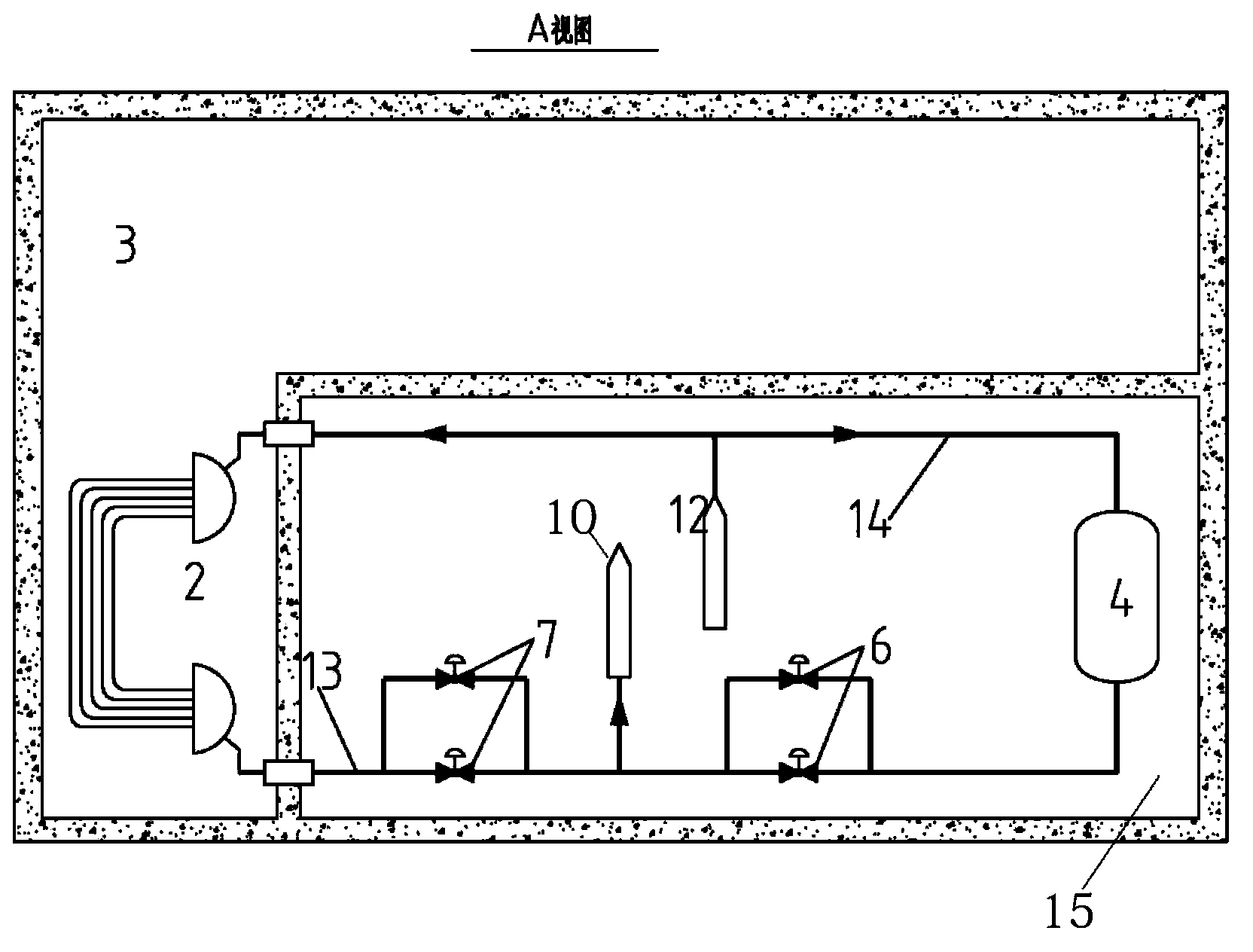

[0029] Such as figure 2 , image 3 As shown, the difference from Embodiment 1 is that the first isolation valve group 6 , the second isolation valve group 7 and the make-up water tank 4 are all arranged in the concrete equipment compartment 15 outside the containment.

Embodiment 3

[0031] The difference from Embodiment 1 is that the first isolation valve group 6 and the second isolation valve group 7 are located inside the containment, and the water supplement tank 4 is arranged in the concrete equipment compartment 15 outside the containment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com