Sleeve and tubular busbar bridging overcurrent fitting for 800kV convertor station

A technology for pipe busbars and converter stations, applied in the installation of busbars, electrical components, cables, etc., can solve the problems of limited space in the valve hall, unguaranteed construction period, and non-compliance with localization, etc., to ensure fixity , to ensure the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

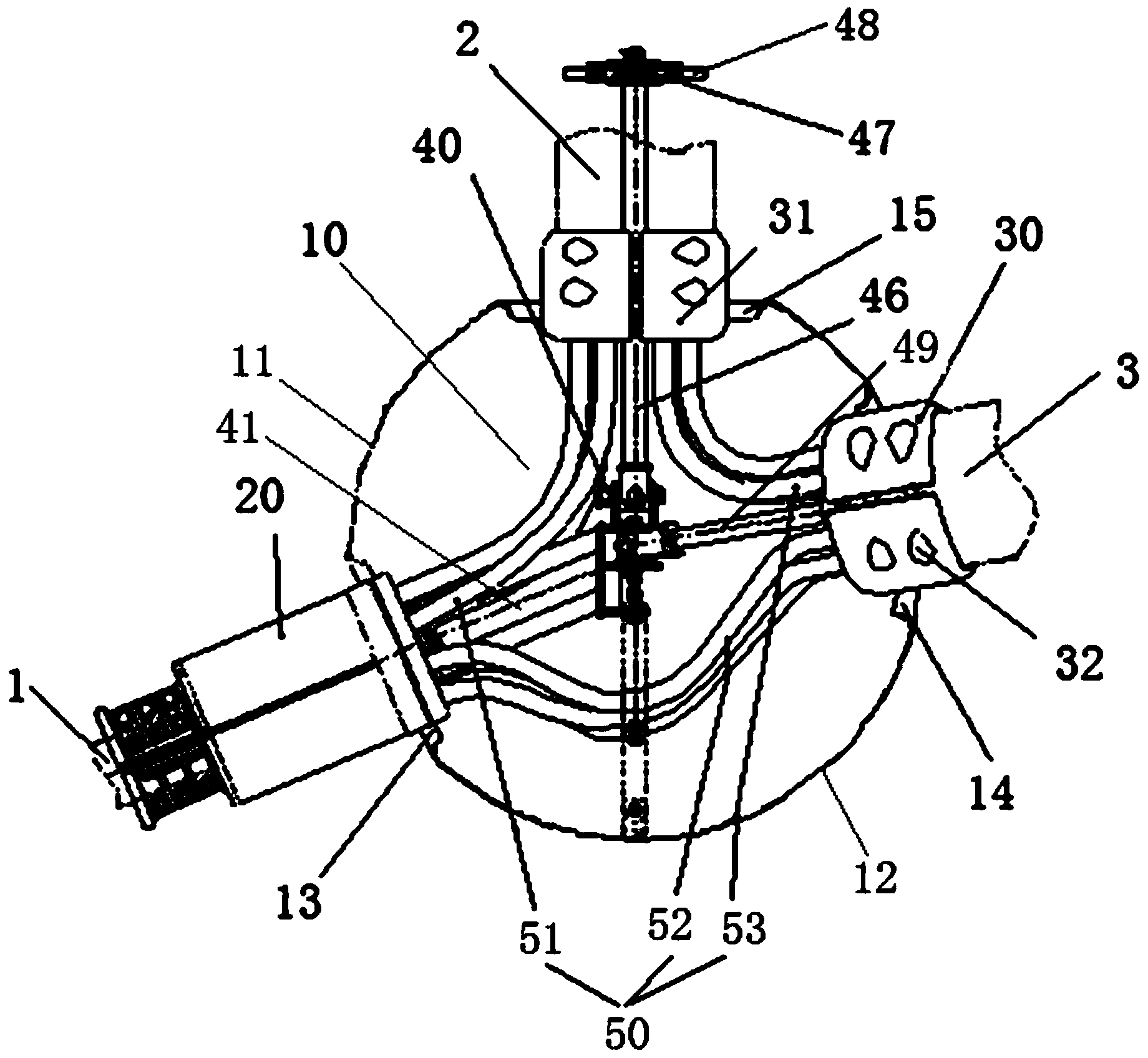

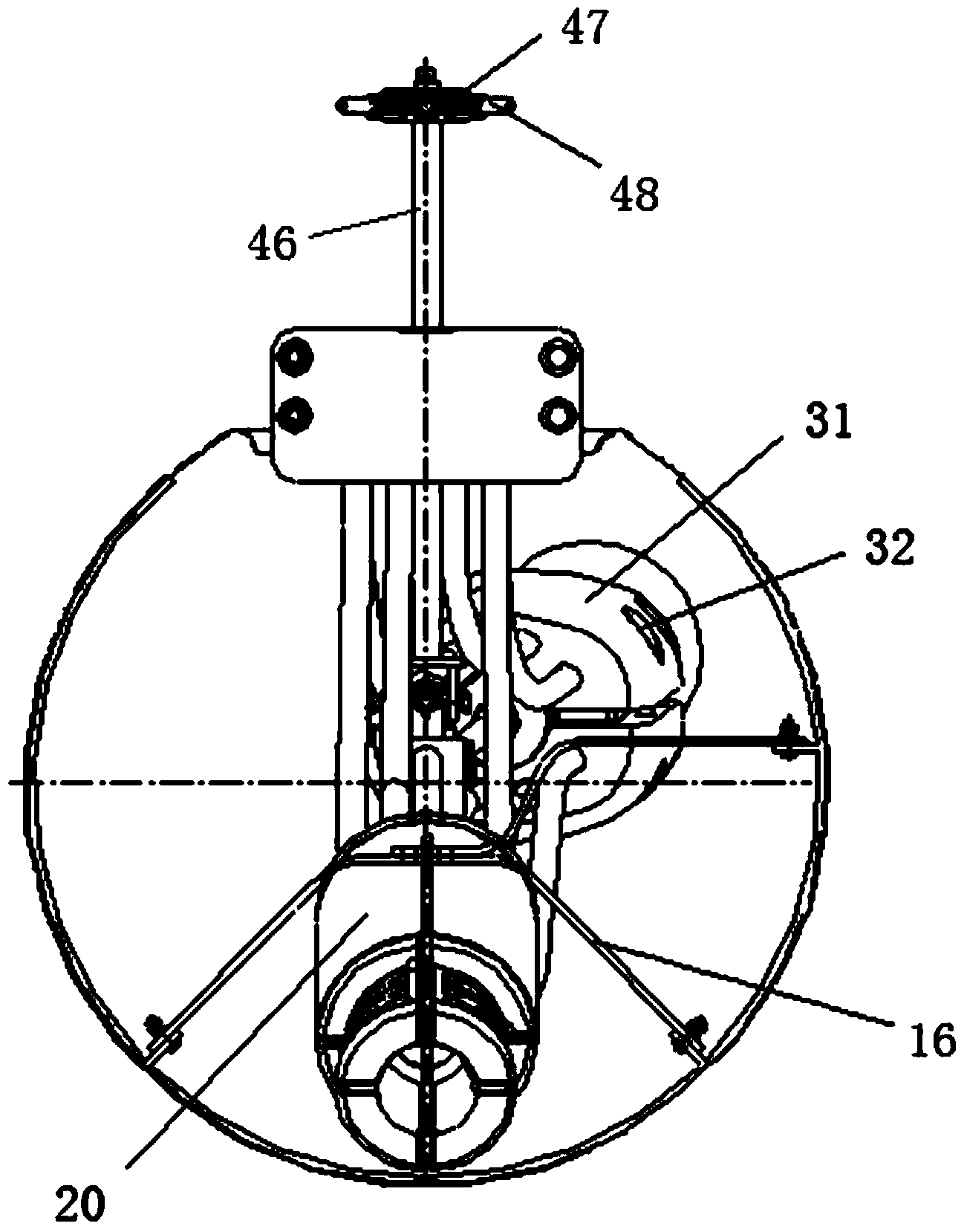

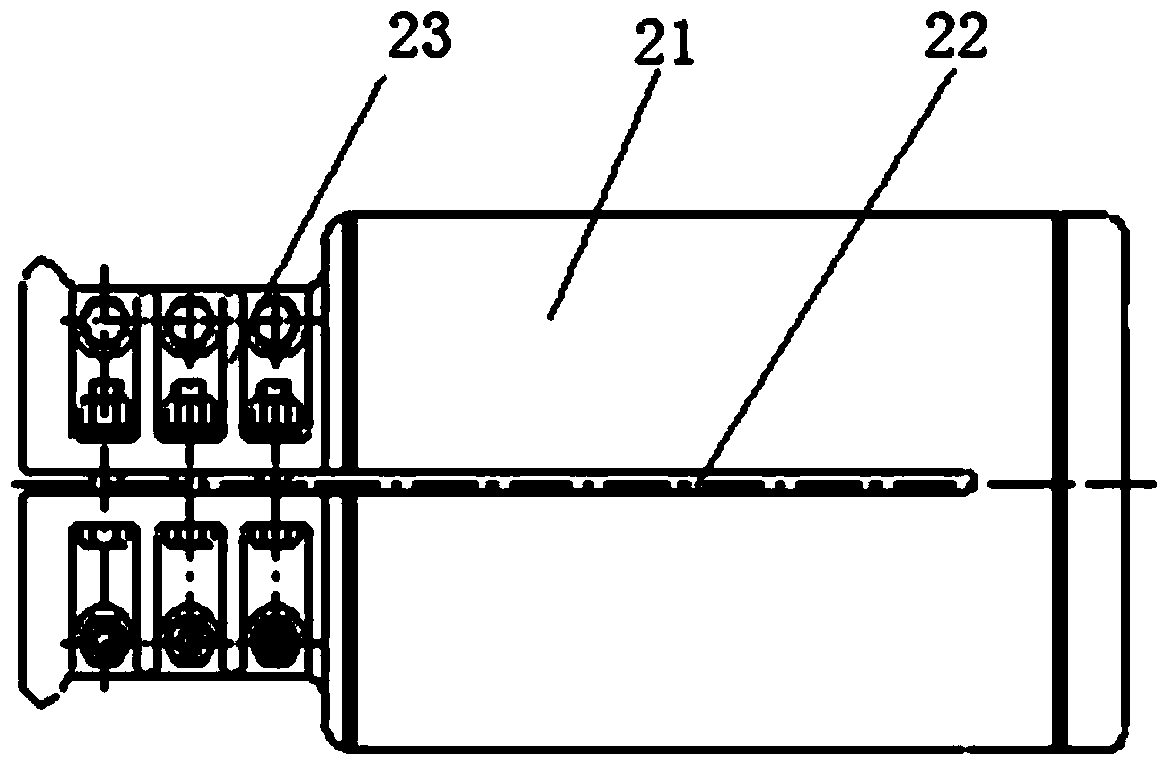

[0018] Such as figure 1 , figure 2 As shown, the present invention includes an anti-sickness ball 10 , a sleeve terminal fixing fitting 20 , two busbar fixing fittings 30 , a universal joint structure 40 and several drain wires 50 .

[0019] The anti-halo ball 10 of the present invention is a shell formed by connecting the left hemisphere 11 and the right hemisphere 12. The upper side wall of the left hemisphere 11 of the shell is provided with a left opening 13 for piercing the sleeve terminal fixing hardware 20. The side wall of the right hemisphere 12 of the housing is provided with a right side opening 14 for piercing the busbar fixing fitting 30, and the top two hemispheres of the housing are provided with a top opening for passing another busbar fixing fitting 30 15. A supporting frame 16 is connected in the left hemisphere 11 and the right h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com