Multi-stage adjustable soil sample grinder

An adjustable and grinding machine technology, applied in grain processing, etc., can solve the problems of complicated soil sample processing, inability to classify soil samples for multiple times, and deviation of experimental results, so as to increase the scope of soil sample processing and avoid multiple times Effect of repeated grinding and simplified pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following implementations. example.

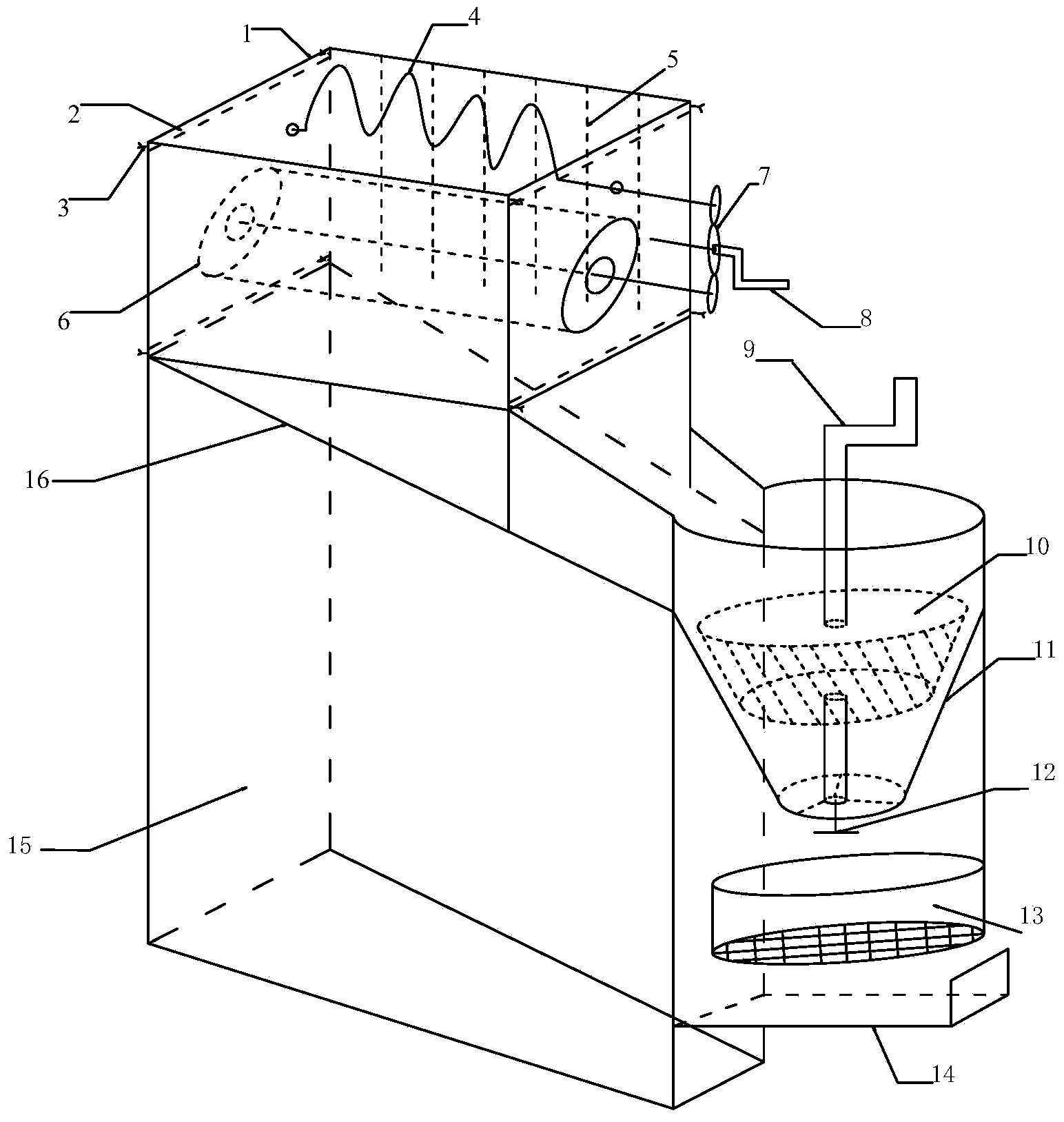

[0020] Such as figure 1 As shown, this embodiment includes a sampling box 1, a rail 2, an adjusting bolt 3, a spiral knife 4, a grinding shaft 6, a gear assembly 7, a first rotating handle 8, a second rotating handle 9, a grinding core 10, a funnel 11, The sample sieve 13, the sample loading box 14, and the bracket 15, the sample injection box 1, the funnel 11, the sample sieve 13, and the sample loading box 14 are respectively fixed on the bracket 15, and the rail 2 is inlaid on the left and right walls of the sample box 1. At the upper and lower ends, the adjusting bolts 3 are arranged on the front and back walls of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com