Novel centralized water supply and air supply system for automobile welding assembly line

A technology of gas supply system and water supply system, which is applied in the direction of pipeline system, auxiliary equipment, welding equipment, etc., which can solve the problems of easy generation of air bubbles in working water, increase of system cost, slow response speed, etc., and save pipeline installation and fixing process , Improve work efficiency and improve response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

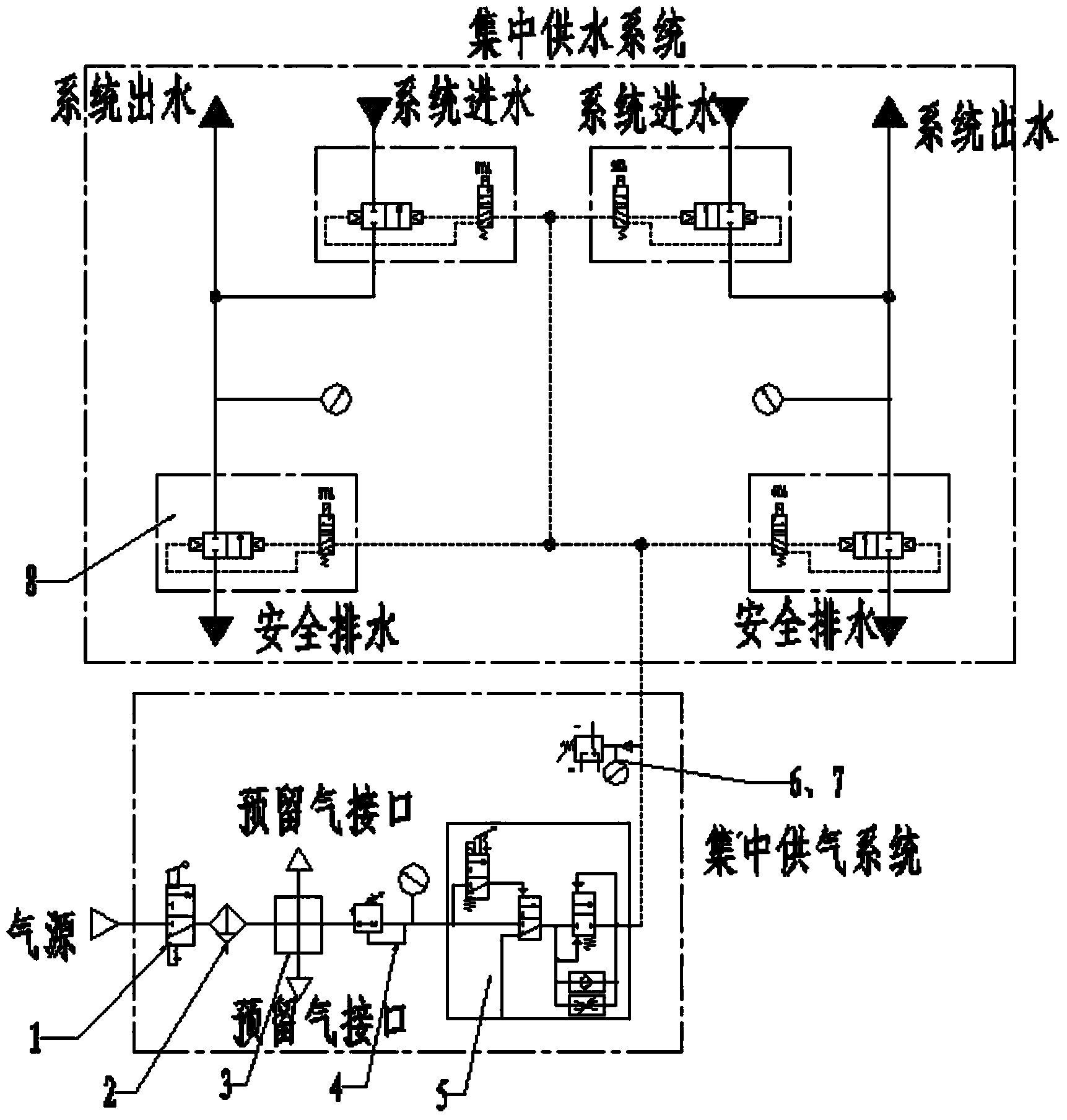

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, a centralized water supply and gas supply system for a new type of automobile welding line includes a centralized water supply system and a centralized gas supply system. The centralized water supply system is provided with an air interface to connect with the centralized gas supply system. The centralized gas supply system The system includes a two-position three-way manual valve 1, a filter 2, an air distribution block 3, a pressure reducing valve 4, a slow start and quick discharge valve 5, a pressure switch 6, and a pressure gauge 7, which are connected in sequence. The coaxial valve 8 is used as the system water outlet, system water inlet and safety drainage valves.

[0012] The present invention utilizes the valve block integration technology and the feature of plug-in installation of coaxial valves to realize the integration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com