Machine for automatic assembly and detection of automotive connector and implementation method of machine

An automotive connector and automatic assembly technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of wasting human resources, inaccurate assembly accuracy, and low production efficiency, reducing labor intensity and improving production efficiency. , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

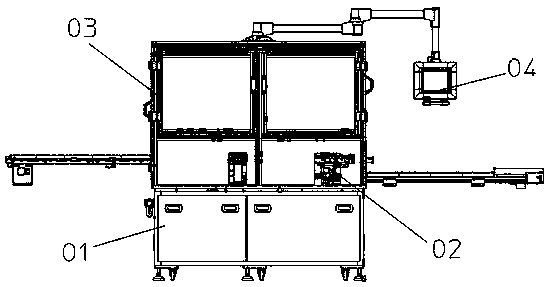

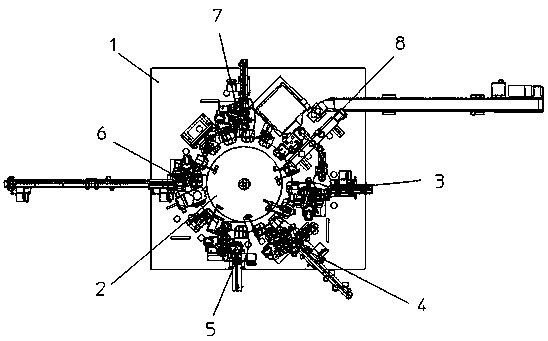

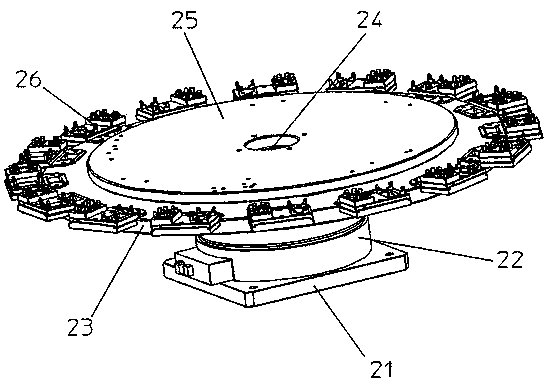

[0050] Such as Figure 1 to Figure 13 As shown, the machine for automatic assembly and testing of automotive connectors includes a cabinet 01 with built-in electrical control components, a molding part 02 connected to the cabinet for product assembly and molding, and installed on the cabinet to protect the protection of the molding part. The cover 03, and the controller 04 used to control the action of the forming part; wherein, the controller can be realized by using the existing general PLC control method, which will not be repeated in this embodiment. The forming part includes a bottom plate 1 connected to the cabinet, a rotary station 2 set on the bottom plate for product rotation cycle assembly, and sealing blocks that are installed on the bottom plate and evenly distributed along the clockwise rotation of the outer circumference of the rotary station Loading inspection station 3, small plastic shell assembly inspection station 4, sealing ring assembly inspection station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com