Wood lathe

A woodworking lathe and bed technology, applied in the field of woodworking lathes, can solve the problems of inconvenient re-installation of the tailstock, scratches on the bottom positioning surface of the tailstock, inconvenient placement of the tailstock, etc., and achieves ingenious design, good economic benefits and social benefits. Effective, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

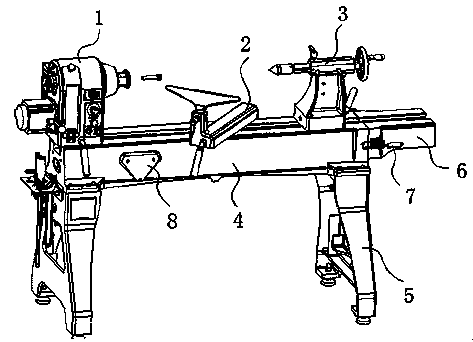

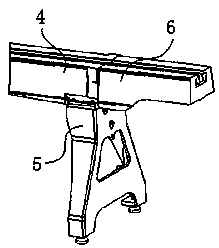

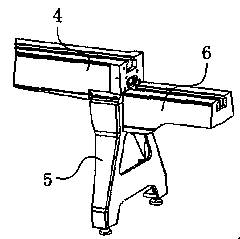

[0024] like figure 1 As shown, the main components of a woodworking lathe include a headstock assembly 1, a tool rest assembly 2, a tailstock assembly 3, a bed 4, legs 5, a bed extension 6, a quick fastening clutch device 7, and a fixing hole 8. Headstock assembly 1, tool rest assembly 2, and tailstock assembly 3 are sequentially arranged on the bed 4, and the bed 4 is arranged on the outrigger 5, which can be fixed to the ground through anchor bolts, and the bed extension 6 is used for To extend the length of the bed 4. Among them, the headstock assembly 1, the tool rest assembly 2 and the tailstock assembly 3 can be commonly used components required by woodworking lathes, for example: the headstock assembly 1 mainly includes a brushless DC motor, a box embedded door, a headstock, and a headstock lock Tight handles, faceplates and fixed top parts, among which the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com