Automotive carpet radiant heating system

A technology for automotive carpet and radiant heating, applied in vehicle components, heating/cooling equipment, air handling equipment, etc., can solve problems such as uneven air temperature distribution, poor comfort, and low ambient air temperature increase, to prevent heat consumption. , temperature balance, improve the effect of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

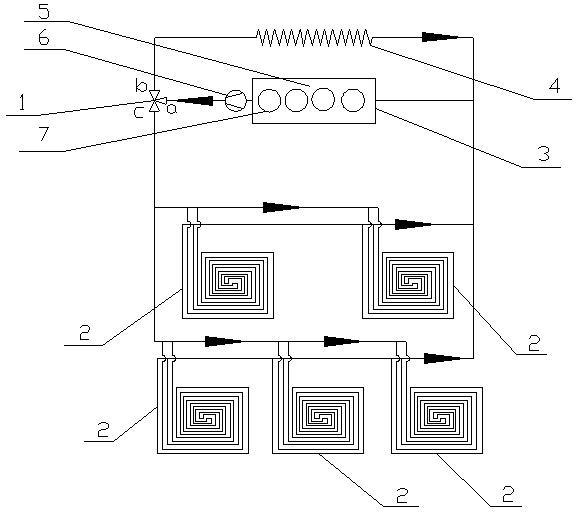

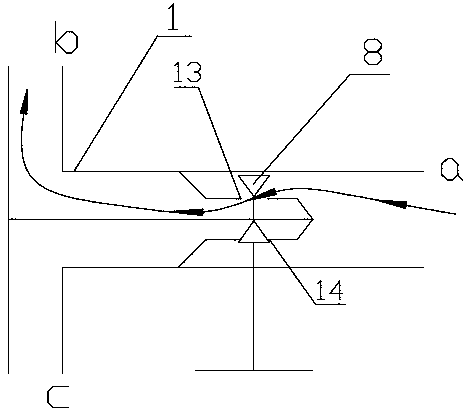

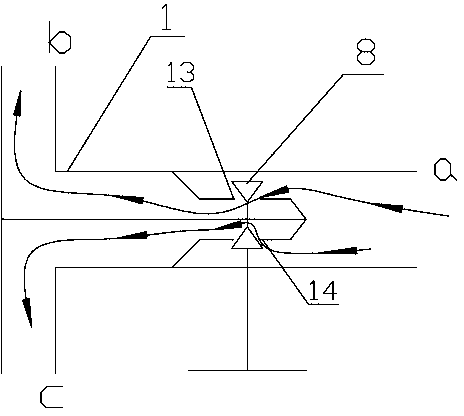

[0016] Such as Figure 1 to Figure 4 The car carpet radiant heating system shown includes a car carpet, a body floor, an engine cooling system, a flow regulating valve 1 and five coil radiators 2, and the engine cooling system includes an engine 3 (which has a cylinder 7 and a water jacket 5), radiator 4 and water pump 6, the water inlet of the water pump 6 is connected to the coolant outlet of the engine 3 through a pipeline, and five coil radiators 2 are arranged in parallel between the car carpet and the vehicle body floor (the coil radiator 2 and the vehicle body floor There is a heat insulation layer on the contact surface), two coil radiators 2 are connected in parallel in the front row, and three coil radiators 2 are connected in parallel in the rear row. The coil radiator 2 adopts floor heating coils, and each coil radiator 2 All have a first water inlet pipe 9, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com