A hydrothermal drum high temperature composting reactor

A technology of high-temperature composting and reactors, applied in applications, organic fertilizers, fertilization devices, etc., can solve problems such as secondary pollution, loss of nitrogen and phosphorus nutrients, and large footprint, to achieve improved efficiency, high controllability, Controllable effect of oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

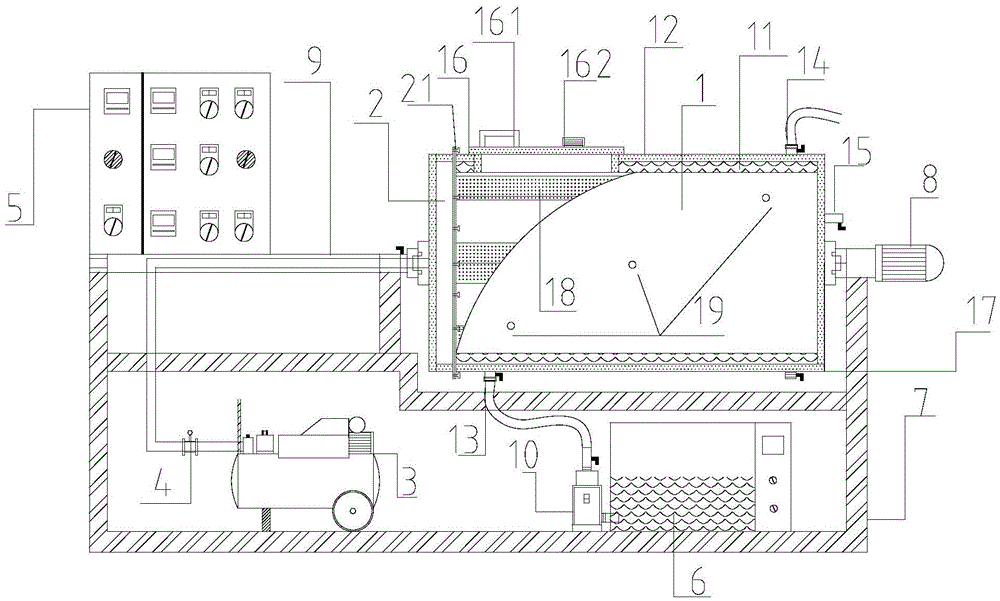

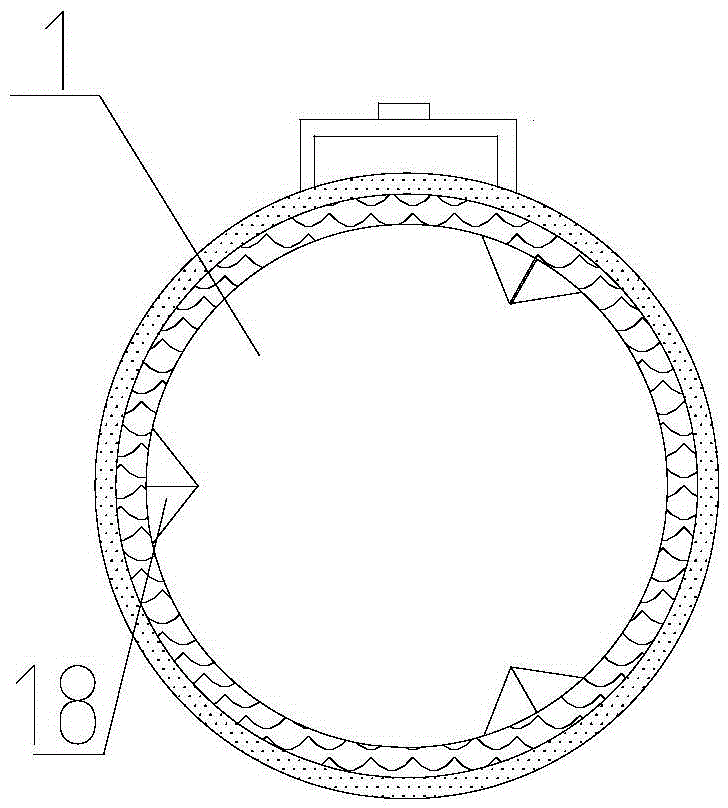

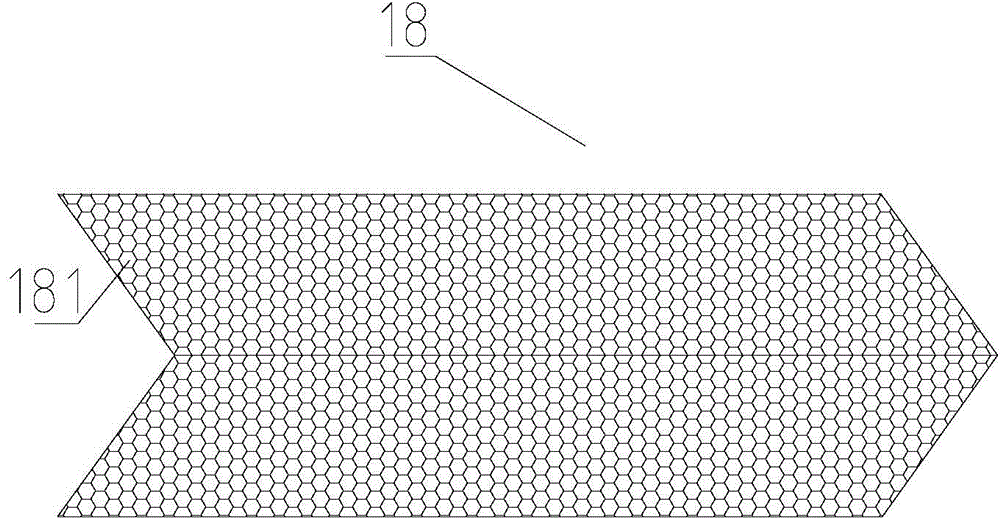

[0018] The structure of the hydrothermal drum high temperature composting reactor is as follows: figure 1 with figure 2 As shown, the inner wall is provided with a temperature control cylinder 11, and the outer wall is provided with a polystyrene foam insulation layer 12, a water inlet valve 13 and a return valve 14. The two ends of the main reaction tank 1 are respectively provided with an air distribution chamber 2. , exhaust valve 15 and inlet and outlet, a cavity is formed between the temperature control cylinder 11 and the inner wall of the main reaction tank, and the temperature of the reaction system can be adjusted by filling hot water or hot steam, and the polystyrene foam insulation layer 12 can be To prevent heat loss, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com