Oil charge and discharge control valve for coupler

A technology of oil discharge control and coupling, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of high motor failure rate, complex structure, high failure rate, etc., to ensure the oil pressure balance of the system and the overall structure is simple , the effect of simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

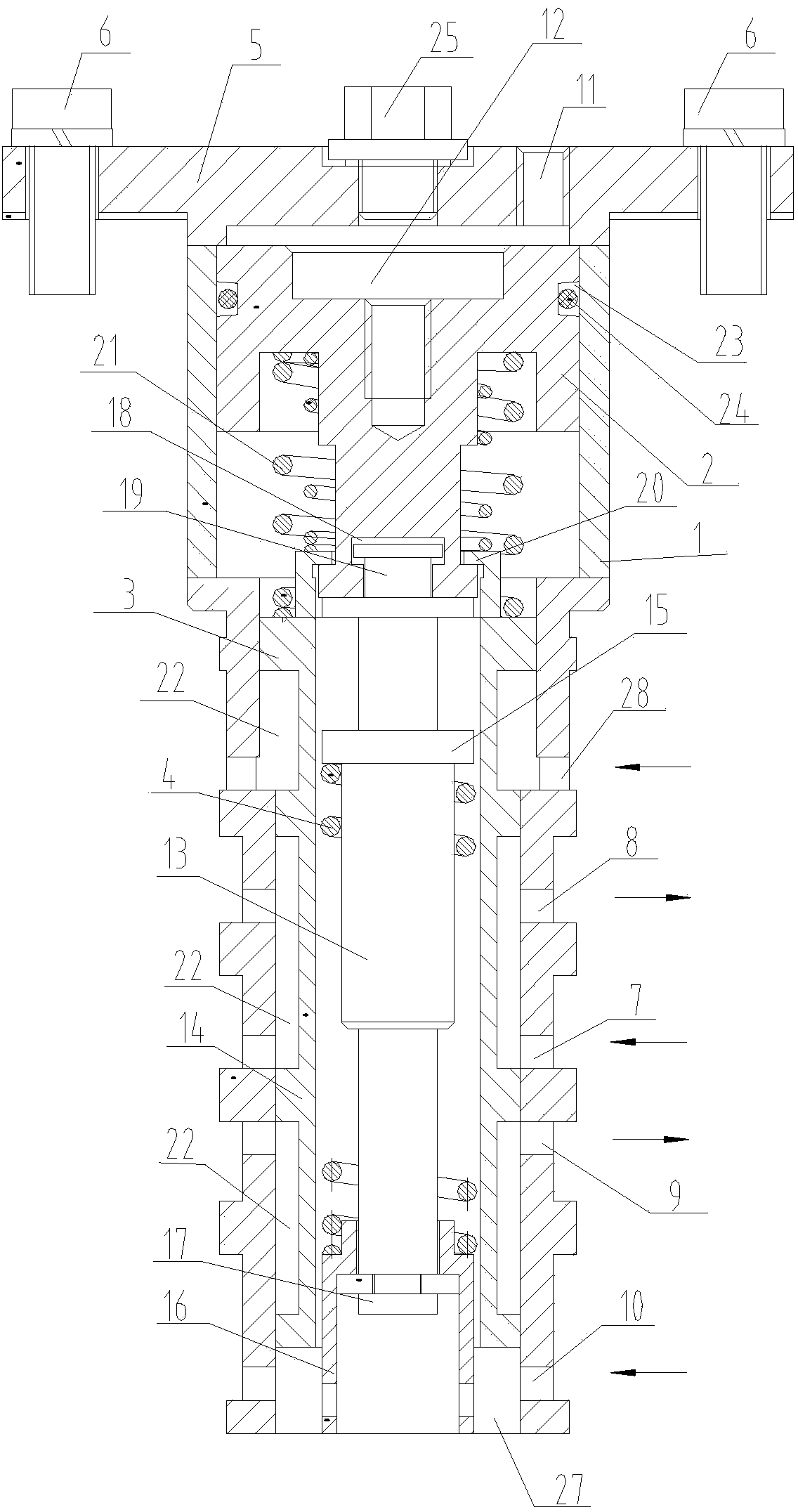

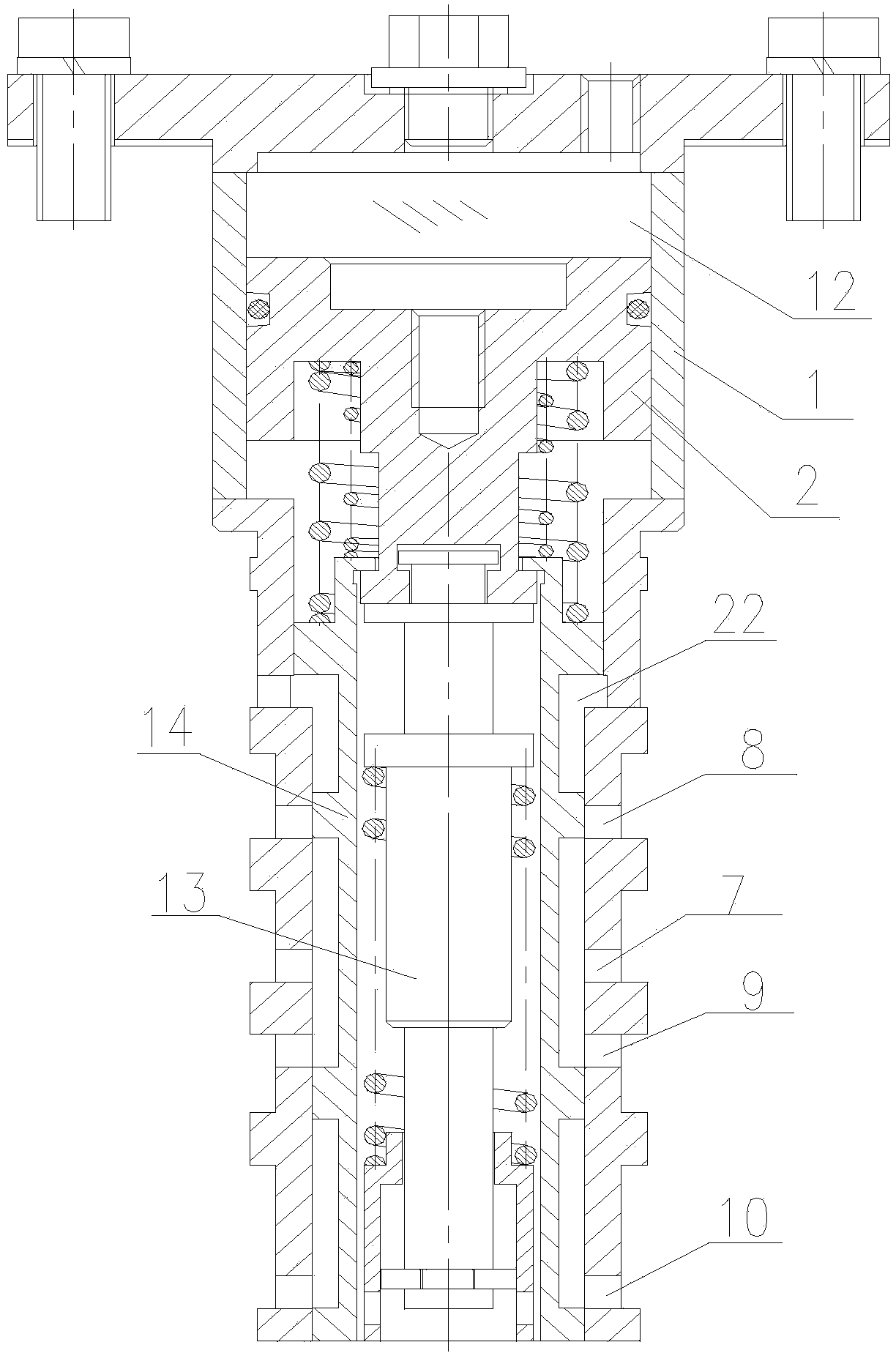

[0020] Such as figure 1 and figure 2 As shown, a coupling oil filling and discharging control valve provided by the present invention includes a valve body 1, and the valve body 1 is fixed on the control valve mounting seat of the coupling (not shown in the figure), and the valve body 1 is provided with Piston 2, control spool 3 and return spring 4, the bottom of piston 2 is connected to the top of control spool 3, piston 2 drives control spool 3 to move, piston 2, control spool 3 and the inner wall of valve body 1 slide connect. There is a detachable gland 5 on the top of the valve body 1 , the gland 5 compresses the valve body 1 and is fixedly connected to the control valve mounting seat by bolts 6 .

[0021] The valve body 1 is provided with an oil inlet 7 and an oil return port 8 connected with the coupling, an oil filling port 9 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com