Side-pole multi-voltage nickel-metal hybrid battery module

A technology for nickel-metal hydride batteries and battery modules, which is applied in nickel storage batteries, battery pack components, secondary batteries, etc., can solve the problem of reducing the service life of battery modules, threatening the safety of battery module equipment, and high requirements for single cell sealing. problem, to avoid the danger of short circuit, improve the service life, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

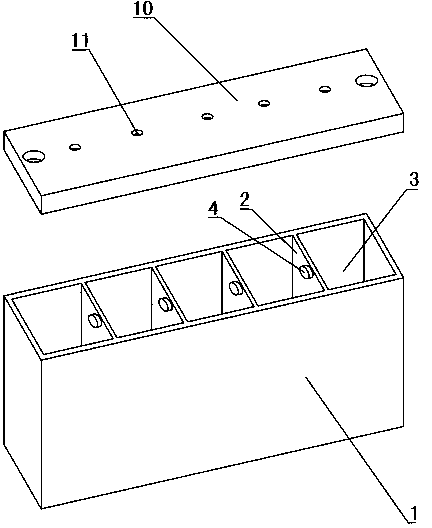

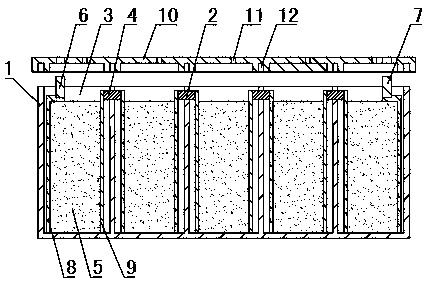

[0027] Embodiment 1, with reference to Figure 1~2 , the side pole multi-voltage Ni-MH battery module, including the battery module casing 1 and the battery cell 5, the battery cover 10 is fixed on the upper opening of the battery module casing 1, and the inner cavity of the battery module casing 1 is vertically provided with four compartments plate 2, which evenly partitions the inner cavity of the battery module housing 1 into five mutually sealed single battery cavities 3, each single battery cavity 3 is respectively packaged with a battery cell 5, and the separator 2 is fixed with a The conductive columns 4 of the two single battery chambers 3, and the two adjacent cells 5 are connected in series through the conductive columns 4, and the cells 5 located on both sides of the battery module casing 1 are respectively connected to the positive pole 6 and the Negative pole 7.

[0028] The material of the conductive column 4 is high-purity iron, which is convenient for welding ...

Embodiment 2

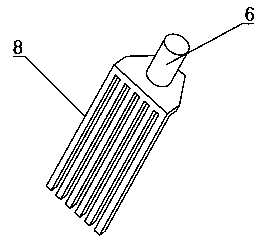

[0036] refer to Figure 7 In the present invention, the positive pole 6 can also be connected to the middle of the positive current collector 8, the negative pole 7 can be connected to the middle of the negative current collector 9, and the positive pole 6 and the negative pole 7 can be separated from the two vertical sides of the battery module case 1 respectively. wear out. The positive pole 6 and the negative pole 7 are arranged on the side of the battery module casing 1, so that the current flows in the direction of the positive pole 6 or the negative pole 7 in the middle, and the current path lengths at the upper and lower parts of the pole piece are the same, which overcomes the problem of the original battery positive pole. The upper current path is short, the lower current path is long, and the lower part of the battery is prone to heat. In order to facilitate assembly, the two sides of the battery module casing 1 are respectively a left cover 13 and a right cover 14. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com