Ceramic honeycomb filter and manufacturing method thereof

A ceramic honeycomb and filter technology, applied in membrane filters, ceramic products, chemical instruments and methods, etc., can solve the problem of reducing the effective area, unable to meet the PM capture performance and pressure loss characteristics, differential pressure loss characteristics, etc. problem, to achieve the effect of high capture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

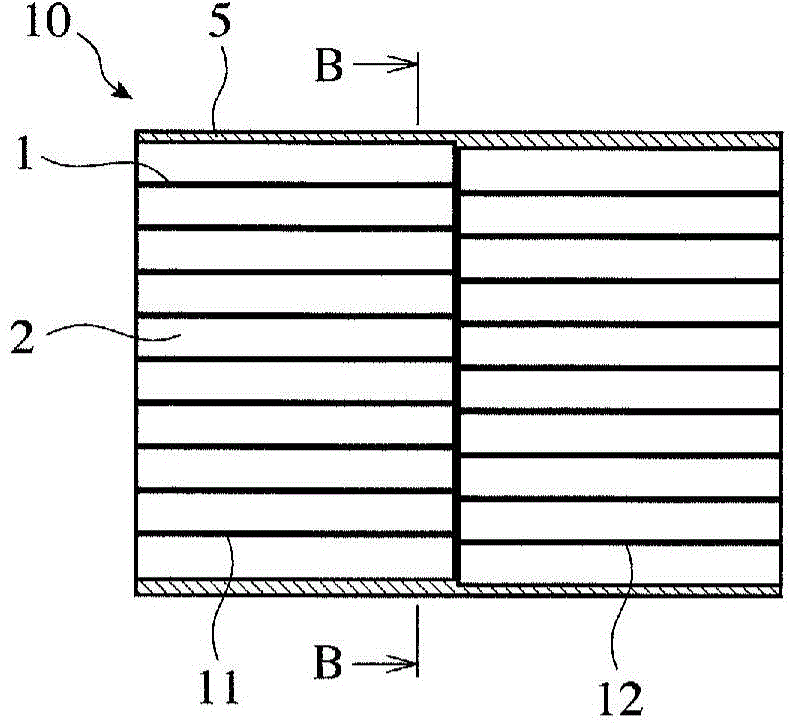

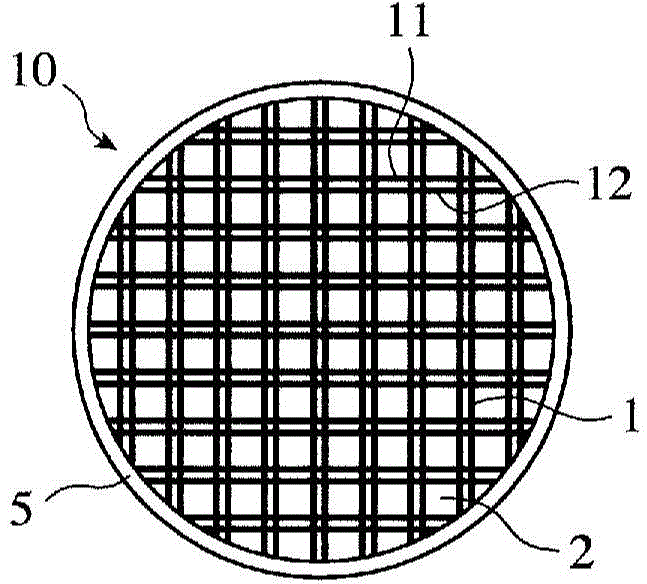

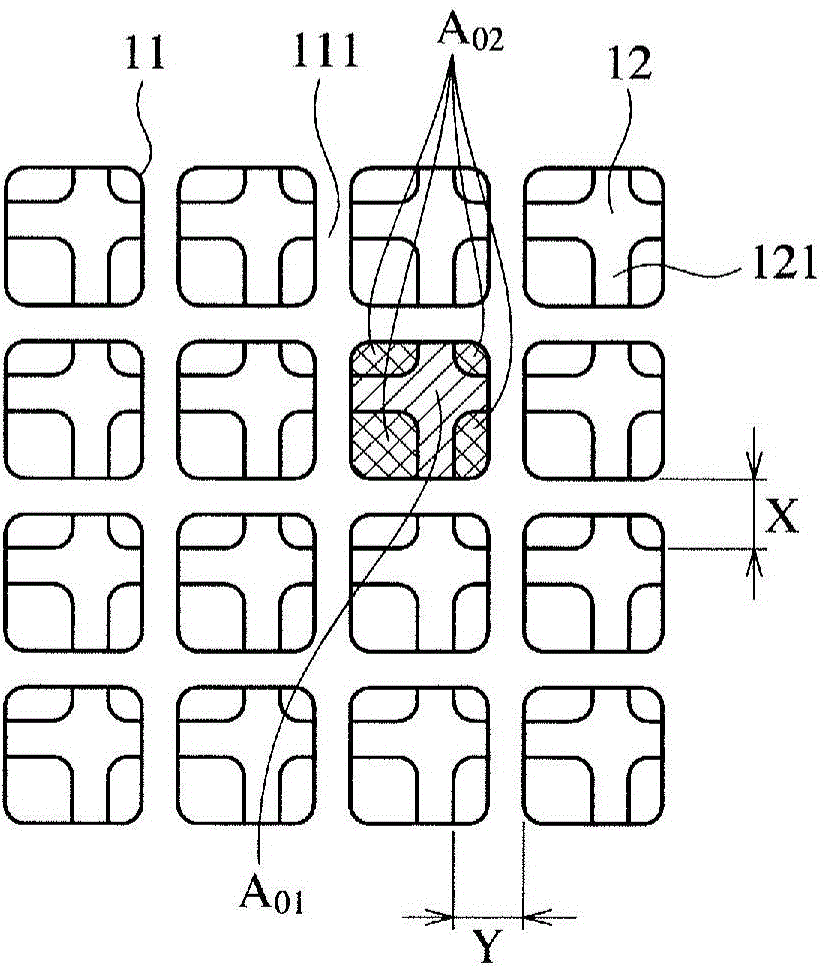

[0159] Using bonding equipment 80 [see Figures 15(a) to 15(e) ], two 150 mm long dry ceramic honeycomb structures C are displaced by 0.3 in each cell wall thickness direction [in each of the X and Y directions shown in Fig. The hole wall spacing is arranged end-to-end. No adhesive material is used on the opposite end surfaces. The arranged two dry ceramic honeycomb structures were sintered in a sintering furnace at a maximum temperature of 1410 °C for 8 days. A slurry including cordierite, a binder, and water was applied to the peripheral surface of the sintered ceramic honeycomb structure and dried to manufacture a ceramic honeycomb filter having an outer diameter of 270 mm and a length of 300 mm.

example 2

[0161] A ceramic honeycomb filter having an outer diameter of 270 mm and a length of 300 mm was manufactured in the same manner as in the example, except that the two desiccators were displaced by 45° in the direction of rotation around their central axis with their cell walls.

example 3

[0163] Adopt bonding equipment 80, two 150mm long dry ceramic honeycomb structures C with their cell walls on each cell wall thickness direction [in each of the X and Y directions shown in Fig. 2 (a) ] displaced by 0.1 times the cell wall spacing are arranged end-to-end via a bonding material comprising a cordierite forming material, a binder and water. The bonding material is a dry ceramic honeycomb structure C [see Figure 14(a) with 14(b) ] The end surface of the hole is 2 times thicker than the spacing of the holes. The arranged two dried ceramic honeycomb structures were sintered in a sintering furnace at a maximum temperature of 1410° C. for 8 days to manufacture a ceramic honeycomb filter with an outer diameter of 266.7 mm and a length of 301 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com