Processing process for honey flavor black tea

A processing technology and a honey-flavored technology, which is applied in the field of processing technology of honey-flavored black tea, can solve problems such as lack of processing technology of honey-flavored black tea, and achieve the effects of improving withering process and fermentation process, mellow tea aroma and mellow aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

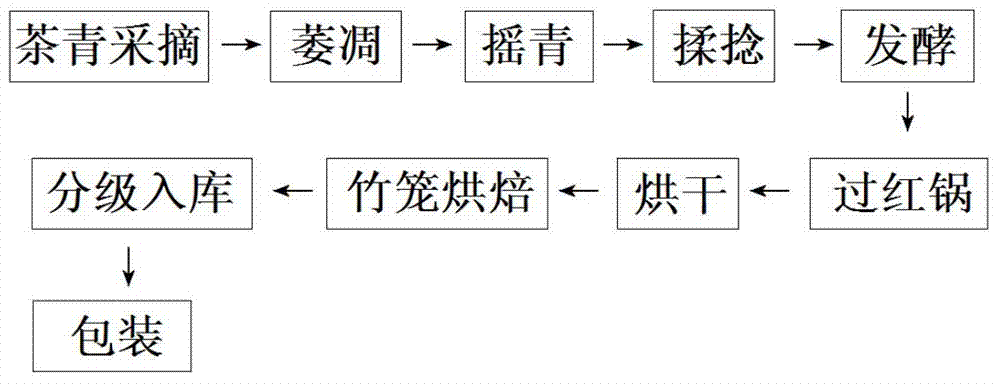

Image

Examples

Embodiment 1

[0032] A processing technology for honey-flavored black tea, specifically comprising the following operations:

[0033] (1) Green tea picking;

[0034] (2) Withering:

[0035] Lay it flat on a white cloth for sunlight withering, and flip it every 10 minutes;

[0036] (3) shake green:

[0037] For the first shaking, the amount of leaves thrown is 1 / 3 of the capacity of the shaking machine, and the time is 1 minute. 1 / 3 of the capacity, time 3min, thinly spread the green leaves on the bamboo sieve, it is advisable that the green leaves do not overlap, let it stand for 1.5h, and shake the green leaves for the third time, the amount of leaves is 1 / 3 of the capacity of the green shaker , about 5 minutes, let stand for 8 hours;

[0038] (4) kneading;

[0039] (5) Fermentation:

[0040] The temperature of the fermentation room should be maintained at 35°C, the relative humidity should be 90%, the thickness of the spread leaves should be 8cm, and the fermentation time should be ...

Embodiment 2

[0052] (1) Green tea picking;

[0053] (2) Withering:

[0054] Lay it flat on a white cloth for sunlight withering, and flip it every 12 minutes;

[0055] (3) shake green:

[0056] For the first shake, the amount of leaf thrown is 1 / 3 of the capacity of the green shaker, and the time is 1.5 minutes. 1 / 3 of the machine capacity, time 4min, thinly spread the green leaves on the bamboo sieve, it is advisable that the green leaves do not overlap, let it stand for 1.5h, and shake the green leaves for the third time, the amount of leaves is 1 / of the capacity of the green shaker 3. The time is about 6 minutes, and it is left to stand for 8 hours;

[0057] (4) kneading;

[0058] (5) Fermentation:

[0059] The temperature of the fermentation room should be maintained at 35°C, the relative humidity should be 92%, the thickness of the spread leaves should be 8.5cm, and the fermentation time should be 190min. Ferment until the tea leaves are orange-yellow and the green gas disappears;...

Embodiment 3

[0068] (1) Green tea picking;

[0069] (2) Withering:

[0070] Lay it flat on a white cloth for sunlight withering, and flip it every 14 minutes;

[0071] (3) shake green:

[0072] For the first shaking, the amount of leaves thrown is 1 / 3 of the capacity of the shaking machine, and the time is 2 minutes. 1 / 3 of the capacity, time 5min, thinly spread the green leaves on the bamboo sieve, it is advisable that the green leaves do not overlap, let it stand for 1.5h, and shake the green leaves for the third time, the amount of leaves is 1 / 3 of the capacity of the green shaker , the time is about 7min, let stand for 8h;

[0073] (4) kneading;

[0074] (5) Fermentation:

[0075] The temperature of the fermentation room should be maintained at 35°C, the relative humidity should be 94%, the thickness of the spread leaves should be 9cm, and the fermentation time should be 200min. Ferment until the tea leaves are orange-yellow and the green gas disappears;

[0076] (6) Over red pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com