Energy stone sanitary towel and manufacturing method thereof

A technology of energy stones and sanitary napkins, applied in the field of women's hygiene products, to achieve the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

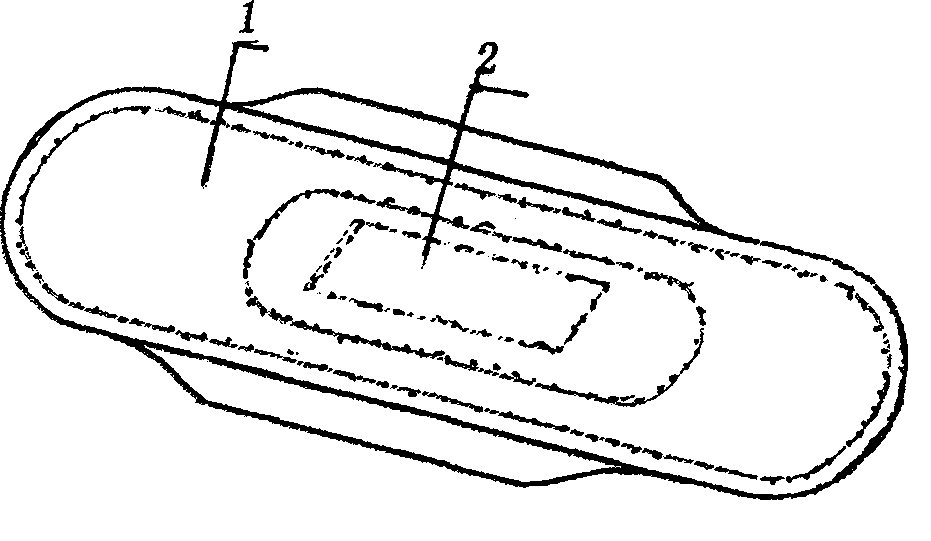

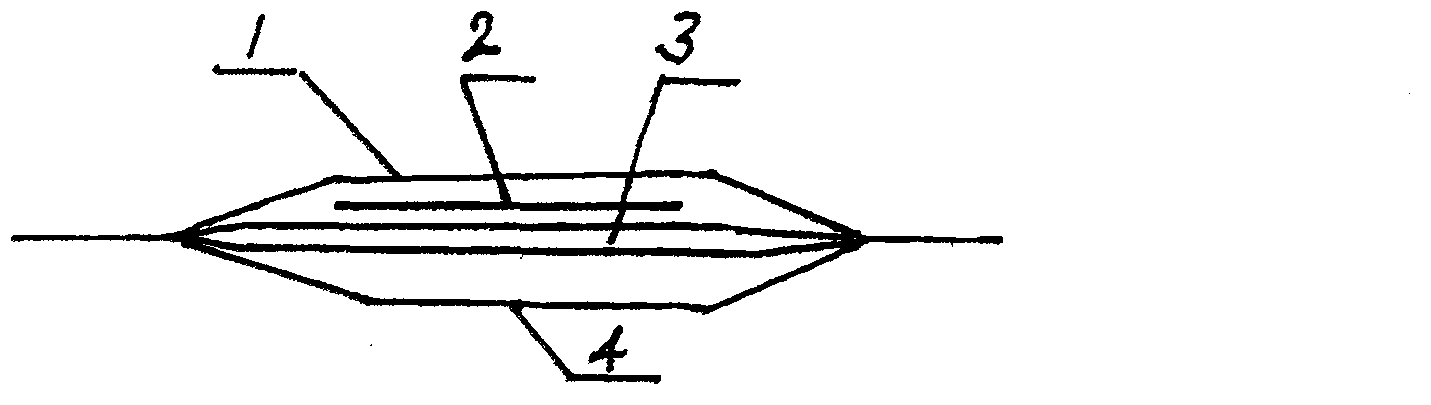

[0018] as attached figure 1 , and attached figure 2 Shown: a energy stone sanitary napkin is layered, including from top to bottom: an outer layer 1, a functional layer 2, a water-absorbing layer 3 and a bottom layer 4, and the layers are fixed with each other by hot sol; it is characterized in that the function Layer 2, is provided with non-woven fabrics containing energy stones; all the other layers are made of known sanitary napkin materials; the non-woven fabric formula composition and production method are as follows: (parts by weight)

[0019] Take 2 parts of medical stone; 1 part of tourmaline; 1 part of germanium stone; 1 part of silver ore; Put it into the kiln for sintering and forming, the furnace temperature range is 1000-1800 degrees, the sintering time is 1-3 hours, take out the furnace to cool, put it into the jet mill after crushing, and process it into a fineness of 0.5-1 Micron ultrafine powder, that is, the energy stone functional powder is obtained; then...

Embodiment 2

[0021] as attached figure 1 , and attached figure 2 As shown: a energy stone sanitary napkin is a layered object, which includes from top to bottom: an outer layer 1, a functional layer 2, a water-absorbing layer 3, and a bottom layer 4, and the layers are fixed with each other by hot melt; it is characterized in that The energy layer 2 is provided with a non-woven fabric containing energy stones, and all the other layers are made of known sanitary napkin materials; the non-woven fabric formula composition and production method are as follows: (by weight)

[0022] Take 10 parts of medical stone; 5 parts of tourmaline; 5 parts of germanium; 5 parts of silver ore; Put it into a kiln for sintering and molding, the furnace temperature range is 1000-1800 degrees, the sintering time is 1-3 hours, it is cooled after it is released from the furnace, it is crushed and put into a jet mill, and processed into a super fineness of 0.5-1 micron. Fine powder, that is, the energy stone fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com