Mesoporous-macroporous composite structure alumina support and its preparation method for hydrodemetallization catalyst, and prepared catalyst

A technology of alumina carrier and macroporous alumina, applied in physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problem that catalysts cannot form more macropores and mesopores, etc. Hydrodemetallization performance, the effect of prolonging the operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

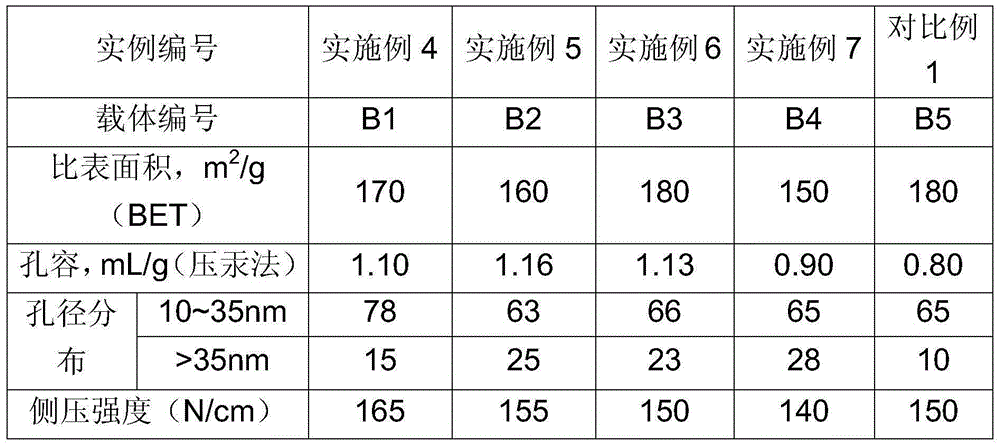

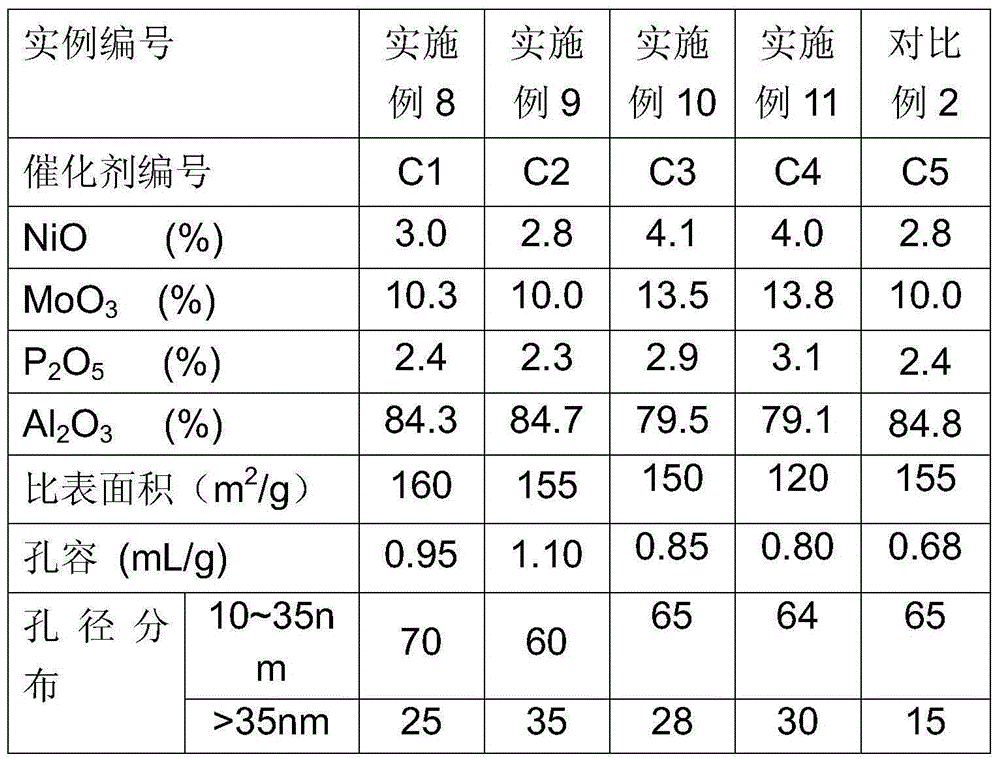

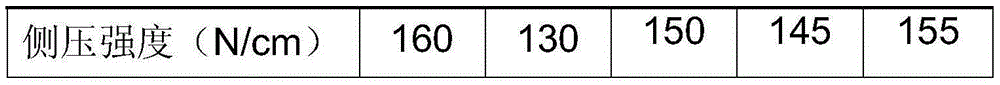

Examples

Embodiment 1

[0031] Put 9.19g of divinylbenzene and 31.25g of styrene (mass ratio of divinylbenzene to styrene: 1:3.4) into a 500mL three-necked flask, and add 2.02g of Span 60 and 0.20g of 2,2′-azo-bis -(2,4-Dimethyl-4-methoxyvaleronitrile) and mix well. Under the condition of stirring, 115 g of deionized water was added dropwise into the three-necked flask to form a reverse-phase concentrated emulsion, so that the amount of water added was 70% of the volume of the obtained reverse-phase concentrated emulsion. The concentrated emulsion was sealed and polymerized in a mold at 50°C for 48 hours, and then dried at 90°C for 24 hours. The obtained macroporous PS template was crushed and sieved to obtain macroporous PS template particles of 50-80 meshes.

[0032] During the preparation of alumina hydrosol, weigh 334g of deionized water into a three-necked flask, add 26.7g of pseudo-boehmite under stirring conditions, add nitric acid dropwise to maintain the pH at 3, and obtain a stable alumina ...

Embodiment 2

[0035] Put 9.19 g of divinylbenzene and 37.70 g of styrene (mass ratio of divinylbenzene to styrene: 1:4.1) into a 500 mL three-necked flask, and add 9.38 g of Span 60 and 0.70 g of azobisisobutyronitrile into it. and mix well. Add 190 g of deionized water dropwise to a three-necked flask under stirring to form a reverse-phase thick emulsion, so that the amount of water added is 75% of the volume of the obtained reverse-phase thick emulsion. The concentrated emulsion was sealed and polymerized in a mold at 85°C for 12 hours, and then dried at 60°C for 36 hours. The obtained macroporous PS template was crushed and sieved to obtain macroporous PS template particles of 50-80 meshes.

[0036] During the preparation of alumina sol, weigh 334g of deionized water into a three-necked flask, add 66.8g of pseudo-boehmite under stirring conditions, add nitric acid dropwise to keep the pH at 4.0, and obtain a stable alumina hydrosol after 3 hours.

[0037]The obtained macroporous PS part...

Embodiment 3

[0039] Put 9.19g of divinylbenzene and 34.92g of styrene (mass ratio of divinylbenzene to styrene: 1:3.8) into a 500mL three-necked flask, and add 5.29g of Span 80 and 0.44g of 2,2′-azo-bis -(2,4-Dimethyl-4-methoxyvaleronitrile) and mix well. Under the condition of stirring, 320 g of deionized water was added dropwise to the three-necked flask to form a reverse-phase concentrated emulsion, so that the amount of water added was 85% of the volume of the obtained reverse-phase concentrated emulsion. The concentrated emulsion was sealed and polymerized in a mold at 70°C for 24 hours, and then dried at 80°C for 30 hours. The obtained macroporous PS template was crushed and sieved to obtain macroporous PS template particles of 50-80 meshes.

[0040] During the preparation of alumina sol, weigh 334g of deionized water into a three-necked flask, add 16.7g of pseudo-boehmite under stirring conditions, add nitric acid dropwise to maintain the pH at 3.5, and obtain a stable alumina hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com