A kind of preparation method of monodisperse nano-starch microspheres with controllable particle size

A nano-starch, monodisperse technology, which is applied in the direction of non-active ingredient medical preparations, powder delivery, pharmaceutical formulations, etc., can solve the problems of unreachable, large size, and inability to control the particle size of microspheres, and achieve good application effects , Uniform size, good targeting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

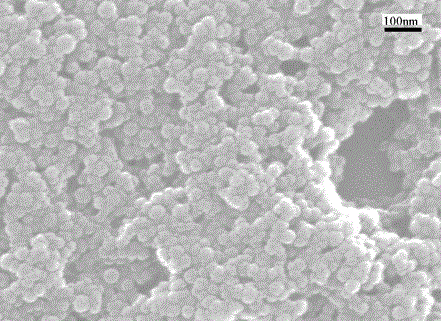

[0039] Embodiment 1: 150g soluble starch is dissolved in 1350g distilled water, is mixed with the starch solution that concentration is 10%. 600 g of water-soluble surfactant Tween20 and 6.1 g of inorganic salt NaCl were added to the solution, and the pH was adjusted to 9-10 with NaOH solution to obtain an aqueous phase. In addition, 1600g of oil-soluble surfactant Span80 and 53g of co-surfactant n-propanol were added to 4000g of organic solvent kerosene to obtain an oil phase. The oil phase and the water phase were mixed, mechanically stirred evenly, and left to stand for 2 hours to obtain a water-in-oil microemulsion.

[0040] Add the above-mentioned water-in-oil starch microemulsion into a 10000ml four-necked flask, stir mechanically (rotating speed 400rpm), pass nitrogen protection (gas flow rate is 10ml / min), add 32g crosslinking agent N,N-methylenebis Acrylamide, 5.6g water-soluble initiator ammonium persulfate, heat up to 45°C, keep warm at this temperature for 5h to c...

Embodiment 2

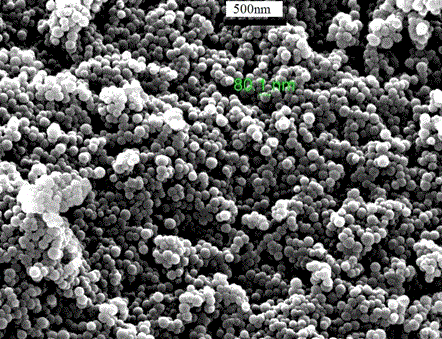

[0041] Embodiment 2: 100g of soluble starch was dissolved in 700g of distilled water to prepare a starch solution with a concentration of 12.5%. 225g of water-soluble surfactant Tween80 and 2.2g of inorganic salt KCl were added to the solution, and the pH was adjusted to 9-10 with NaOH solution to obtain an aqueous phase. Add 750g oil-soluble surfactant Span60 and 35g co-surfactant n-butanol to 3000g organic solvent kerosene in addition to obtain an oil phase. The oil phase and the water phase were mixed, mechanically stirred evenly, and left to stand for 1.5 hours to obtain a water-in-oil microemulsion.

[0042] Add the above-mentioned water-in-oil starch microemulsion into a 5000ml four-neck flask, stir mechanically (rotating speed 400rpm), pass nitrogen protection (gas flow rate is 10ml / min), add 18g crosslinking agent N,N-methylenebis Acrylamide, 3.5g water-soluble initiator cerium ammonium nitrate, heated up to 55°C, kept at this temperature for 4h to carry out cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com