Airflow grinding equipment and wall breaking method with same for pollen pini

A technology of jet pulverization and equipment, applied in grain processing and other directions, can solve the problems of compressed air consumption, complex structure, low efficiency, etc., and achieve the effect of less consumption, simple equipment structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0019] The first embodiment: a jet milling equipment.

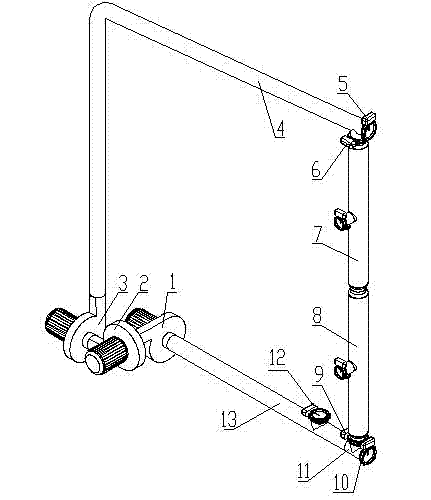

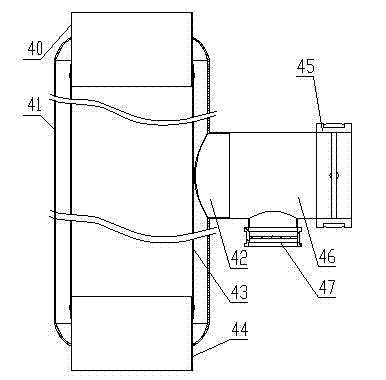

[0020] see figure 1 with figure 2 , the airflow crushing equipment includes fan I1, fan II2, fan III3, circulation pipeline I4, circulation cut-off valve 6, classification device 7, classification device 8, regulating valve 9, air intake tee 11, circulation pipeline II13, the above components According to fan Ⅰ1 outlet, fan Ⅱ2 inlet, fan Ⅱ2 outlet, fan Ⅱ3 inlet, fan Ⅱ3 outlet, circulation pipeline Ⅰ4, circulation stop valve 6, classification device 7 inlet pipe 40, classification device 7 outlet pipe 44, classification device 8 inlet pipe 40. Classification device 8 outlet pipe 44, regulating valve 9, intake tee 11, circulation pipeline II 13, fan 1 inlet are connected in sequence to form a circulation channel, and there is a cleaning port on the circulation pipeline I4, and a cleaning valve 5 is installed on the cleaning port , There is a feeding port on the circulation pipeline II13, and a feeding valve 12 is install...

no. 2 example

[0022] Second embodiment: apply the equipment of the first embodiment to carry out the method for breaking the wall of pine pollen, comprising the following steps:

[0023] S1. Adjustment and start-up of the initial state of the equipment: close the cleaning valve 5, the air inlet valve 10 and the feeding valve 12, open the circulation cut-off valve 6, start the fan I1, the fan II2, and the fan III3, and open the air inlet valve 10 after the fans are started. Adjust the opening of the regulating valve 9 between 5% and 40%, so that the interior of the classifying device 7 and classifying device 8 is in a positive pressure state of 100Pa to 1000Pa;

[0024] S2, feeding: open the feeding valve 12 and add pine pollen with a moisture content less than 10%, the amount of pine pollen added is 20% of the volume of the circulation channel, and the pine pollen enters the circulation channel under the action of gravity and fan negative pressure, and in the air flow Under the action, a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com