A control system and control method for an aluminum ingot casting device

A control system and technology for aluminum ingots, applied in manufacturing tools, foundry workshops, casting equipment, etc., can solve the problems of low production capacity of small aluminum ingots, large space occupied, affecting casting, etc., to facilitate casting, reduce labor intensity, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

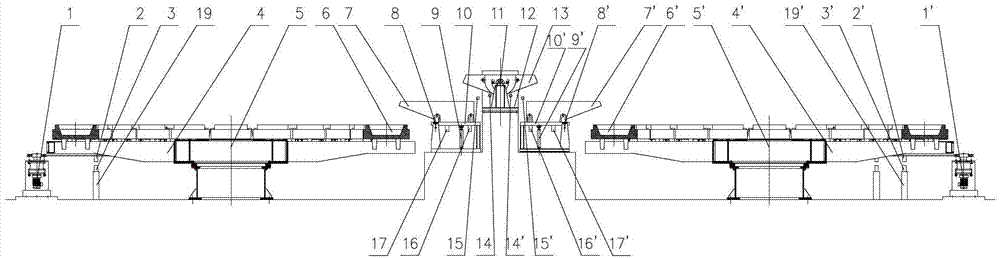

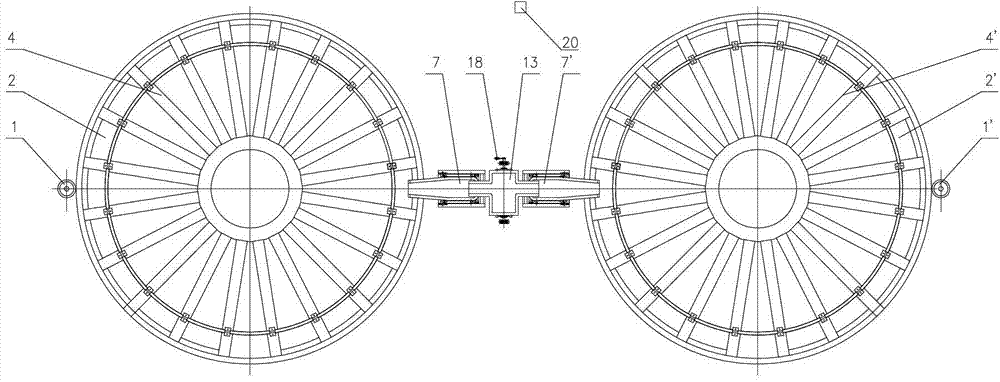

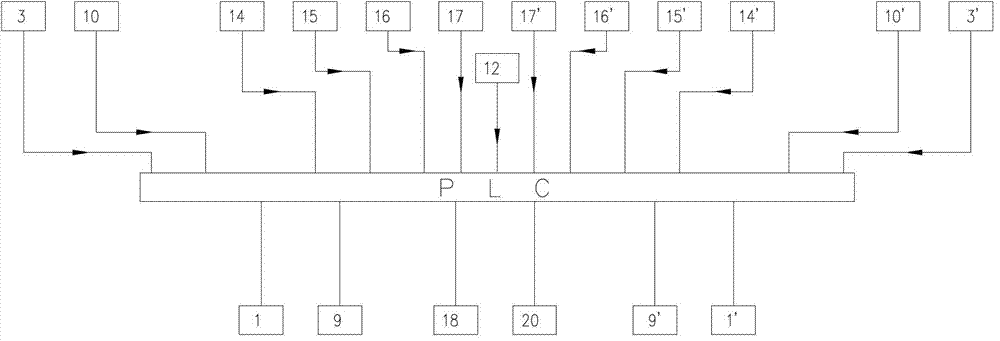

[0056] Such as Figure 1-Figure 3 As shown, the control system of the aluminum ingot casting device of the present invention mainly includes: left disc control system, right disc control system, distributor rotation center 11, No. 2 sensor 12, distributor 13, No. 2 drive device 18, emergency control system Manual switch 20 and PLC controller, etc., the left disc control system and the right disc control system are arranged symmetrically on both sides of the distributor 13, the No. 2 sensor 12 is arranged under the distributor 13, and the distributor 13 is installed on the On the center 11, the distributor rotation center 11 is connected with the No. 2 driving device 18, and the PLC controller is respectively connected with the left disc control system, the right di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com