Hot plate mechanism for water purifying barrel cutting and welding machine

A technology for cutting and welding clean water barrels, which is applied in the field of hot plate mechanism of clean water barrel cutting and welding machines, which can solve the problems of incapable mass production, many human factors involved, poor production quality, etc., and achieve good welding quality and long service life , the effect of high welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

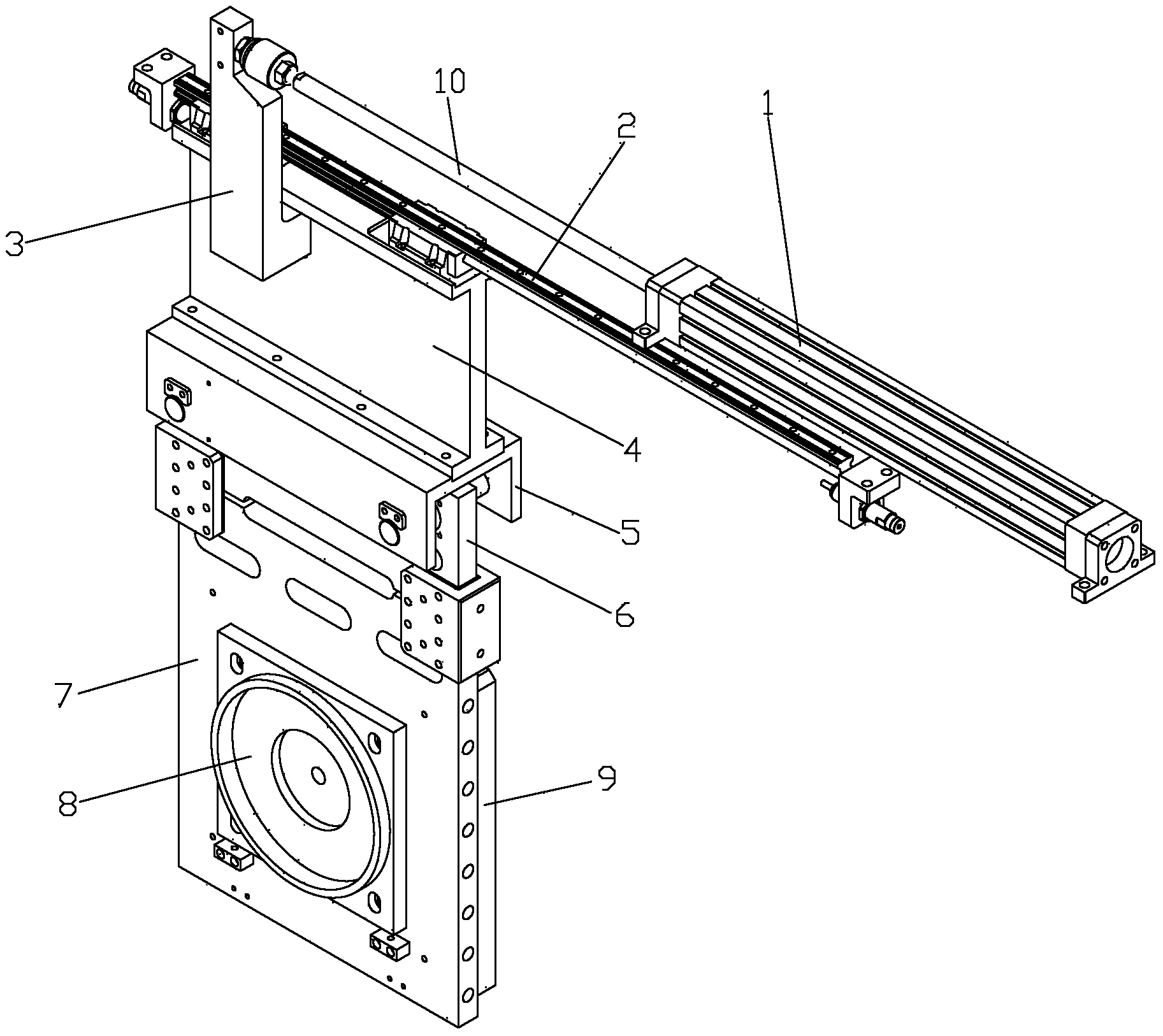

[0012] as attached figure 1 The hot plate mechanism of a clean water barrel cutting and welding machine shown in the present invention includes a cylinder 1, a slide rail 2, a cylinder push block 3, a hot mold upper support plate 4, a hot mold bracket 5, and a hot mold middle Support plate 6, heating plate 7, first hot mold 8 and second hot mold 9; The telescoping rod 10 end of described cylinder 1 is provided with cylinder push block 3; The bottom of described cylinder push block 3 is fixed with hot mold Support plate 4; the upper support plate 4 of the hot mold is arranged on the slide rail 2; the cylinder 1 drives the upper support plate 6 of the hot mold to move along the direction of the slide rail 2, thereby driving the hot plate mechanism to move; the upper support of the hot mold A thermal mold support 5 is fixed below the plate 4; a thermal mold intermediate support plate 6 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap