Winch of depth-indicating safety alarm system

A technology of safety alarm and depth indication, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of high speed of the reel, hidden dangers, power failure protection, etc., and achieve the effect of preventing the nut from forcibly moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

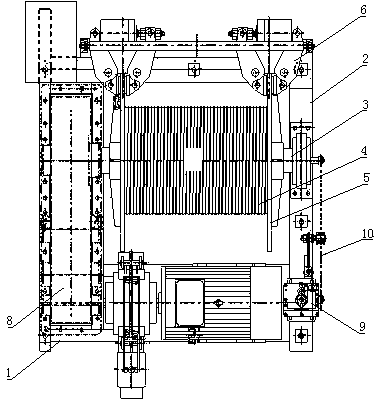

[0020] see figure 1 , the invention discloses a control system comprising a frame, a reel, a driving device, a depth indicator, a transmission monitoring device and a winch;

[0021] The frame includes a base 1 and a bracket 2 installed on the base 1, a reel shaft 3 is horizontally arranged on the base 1, and a reel 4 is installed on the reel shaft 3; brake stops are provided at both ends of the reel 4 Ring 5, brake band assembly 6 is installed outside the two brake retaining rings 5.

[0022] The driving device comprises a driving motor 7 and a reduction box 8. The driving motor 7 is arranged on the base 1 on one side of the reel 4 and is parallel to the reel 4. A brake device 9 is arranged on the output shaft of the driving motor, and the reduction box 8 is installed on the On the base 1 at one end of the reel 4, and set opposite to the support 2.

[0023] The input shaft of the reduction box 8 is connected with the output shaft of the drive motor 7 through a coupling, and...

Embodiment approach

[0031] As a more specific embodiment of the present invention: the limit device includes a limit nut 225, a limit screw 226 and a locking nut 227, the limit nut 225 is welded on the cantilever bracket 221, and the screw connection on the limit nut 2265 is located below the cantilever 222 The limit screw 226 is locked on the limit nut 225 through the lock nut 227 .

[0032] working principle:

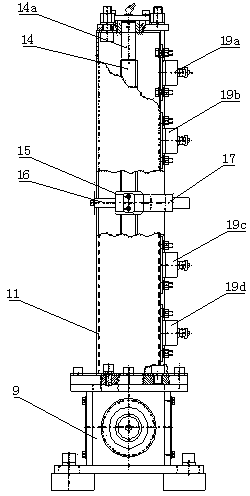

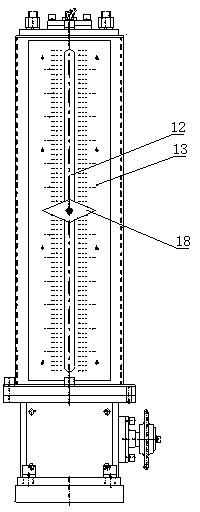

[0033] When the winch works normally, the reel shaft 3 drives the bevel gear in the gearbox 9 to rotate through the chain transmission, so that the screw mandrel 14 rotates; It moves in the vertical direction under the cooperation guide of the indicating groove 12 and the triggering groove.

[0034] When the nut 15 moves upwards or downwards, the position of the suspension point is displayed by the indicator needle 18. Before the upper and lower limit positions are approached, the trigger lever will first push the upper deceleration switch 19b or the lower deceleration switch 19c in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com