Air-flotation and membrane-filtration purification system

A purification system, air flotation membrane technology, applied in chemical instruments and methods, flotation water/sewage treatment, water/sewage multi-stage treatment, etc. High filtration rate, high filtration accuracy, improved load resistance, and reduced self-use water rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

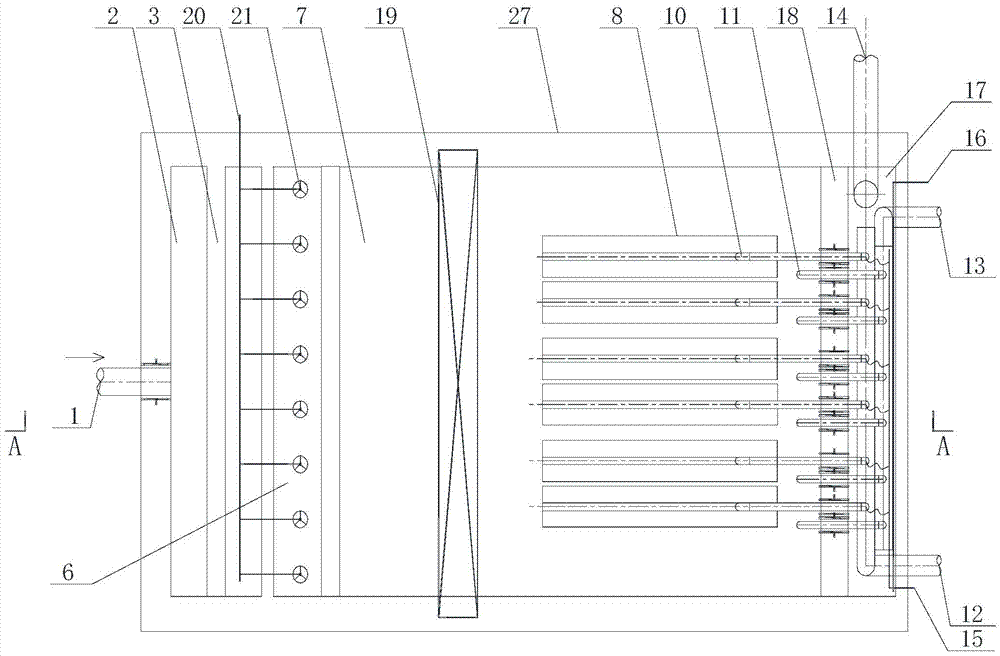

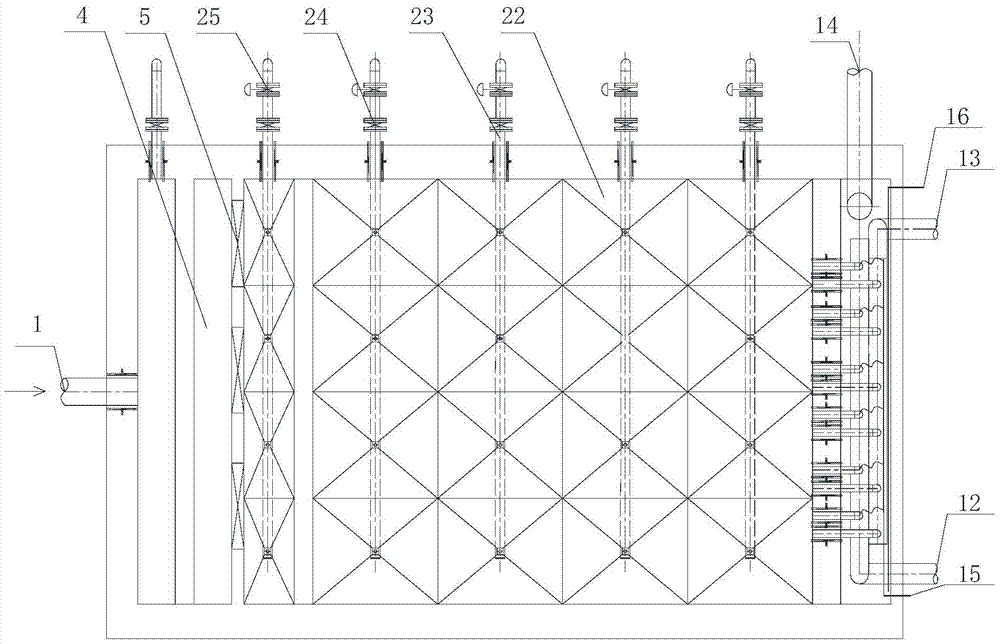

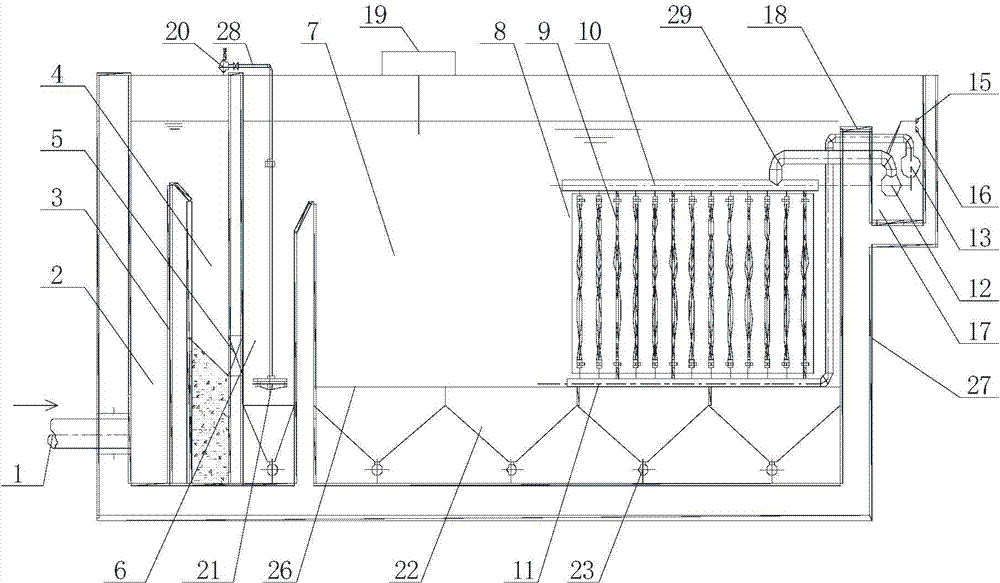

[0057] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown air flotation membrane filtration purification system includes: a filter tank body 27 surrounded by an outer wall, a dissolved air flotation device 28 and a submerged membrane filter device 29 arranged inside the filter tank body 27;

[0058] The interior of the filter body 27 is divided into a water inlet buffer zone 2, a water inlet distribution area 4, an air flotation contact area 6, an air flotation separation area and a membrane filtration water output area 7 by a partition wall;

[0059] The middle interval between the inlet buffer zone 2 and the inlet water distribution area 4 is the inlet water distribution weir 3;

[0060] The outer wall of the filter tank body 27 is provided with a water inlet pipe 1 for communicating with the water inlet buffer zone 2;

[0061] The water inlet distribution area 4 communicates with the air flotation contact area 6 through the water inlet distribution hole 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com